Water Pump Flange

BLUE is a dedicated powder metallurgy manufacturer supplying a wide range of standard automotive water pump components, including water pump flanges and water pump pulleys. All standard parts require no tooling fee, come with competitive pricing, and are kept in stock for immediate ordering.

BLUE Standard Sintered Water Pump Flanges

BLUE provides a variety of flanges for your water pump, covering a wide range of vehicle engine models.

Water Pump Flange

BLUE's high-quality water pump flanges, after heat treatment, offer excellent corrosion resistance, durability, and enhanced hardness and strength.

Auto Water Pump Flange

BLUE auto water pump flange uses iron-based powder as raw material, which has uniform density and good mechanical properties after sintering process.

Mini Water Pump Pulley

BLUE's mini water pump flanges are suitable for compact engine water pumps and provide reliable sealing function.

Powder Metal Water Pump Flange

Our powder metal water pump flanges have a core hole tolerance within ±0.015mm and smooth burr-free threads to ensure secure installation.

Sintered Water Pump Flange

Our sintered water pump flanges are made of MPIF standard 35 FC-0208 as raw material, which has good mechanical strength and durability after sintering.

Powdered Metallurgy Water Pump Flange

BLUE powder metallurgy water pump flanges allow a variety of surface treatment processes to improve performance, including Dacromet and electroplating

Powdered Metal Water Pump Flange

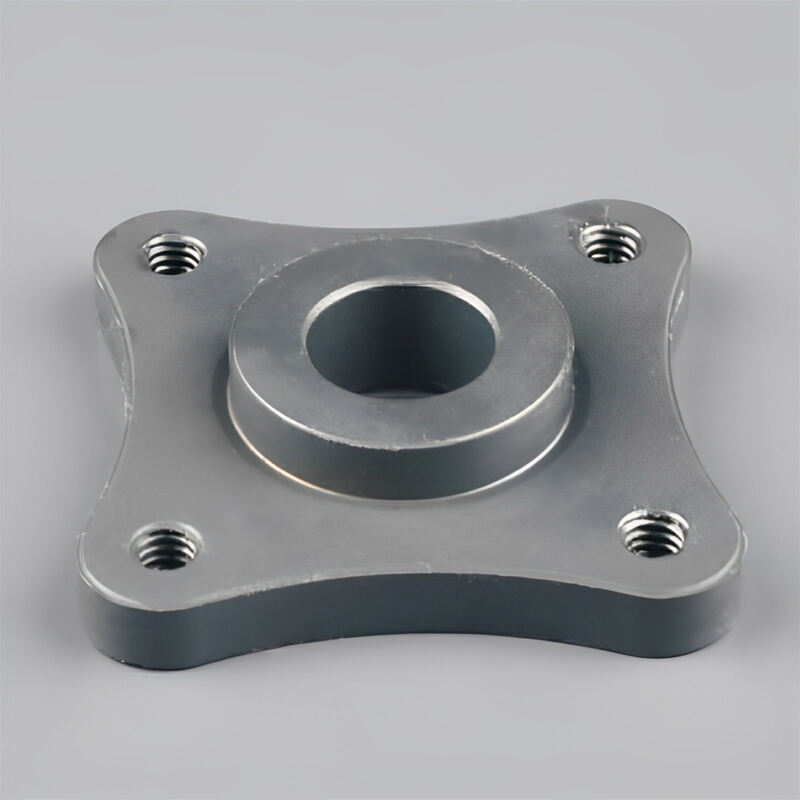

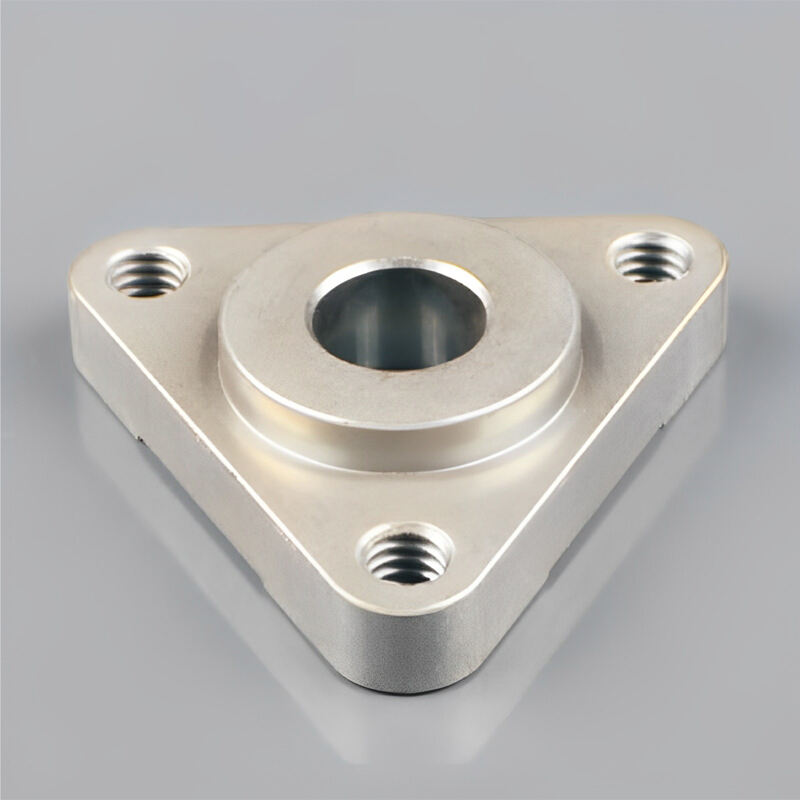

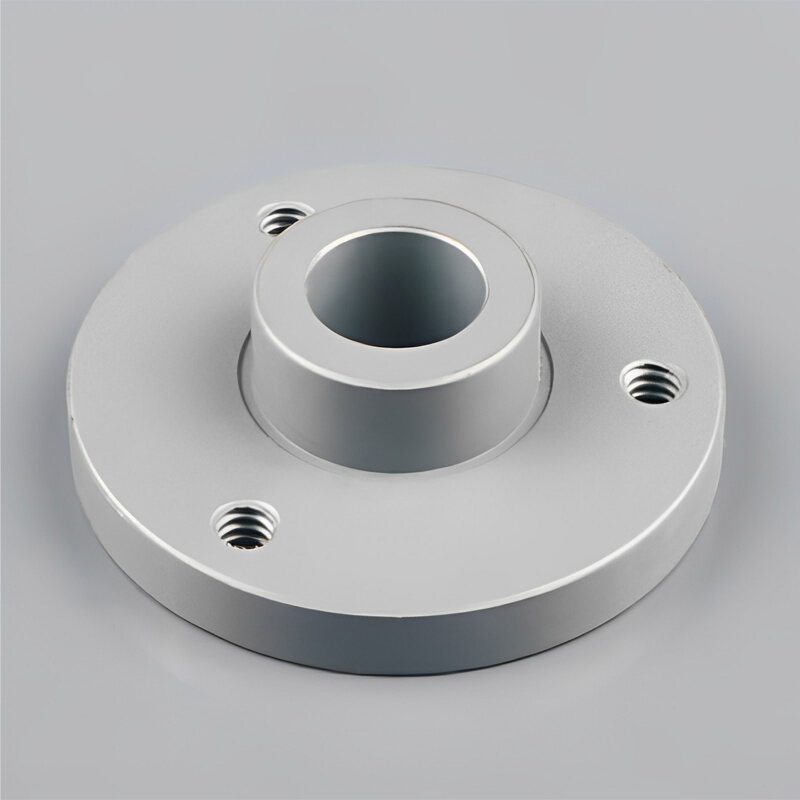

Our powdered metal water pump flanges come in a variety of styles, including round, square, triangular

Sintered Metal Water Pump Flange

BLUE sintered metal water pump flanges can reach a hardness of more than 65HRB after steam treatment, which has a long service life.

R53 Water Pump Flange

R53 water pump flange is the basic part of the automobile engine water pump, which is used to drive the water pump impeller to rotate.

A water pump flange is a connecting component that securely attaches the pump or water pump housing to the engine block or piping system. It provides a flat, bolted surface for a leak-free attachment of the pump’s inlet and outlet to the pipes or housings. Gaskets and/or O-rings are added to the flanges to ensure proper sealing under high pressure and for a long service period.

Common Materials of Water Pump Flange

Steel

Carbon steel, alloy steel, or stainless steel, such as grades 304 or 316, is used to design water pump flanges when there is a need for greater strength and toughness. This material is ideal for applications exposed to mechanical stress where the flange must resist bending, deformation, impact, or fluctuating loads. Steel flanges often undergo additional treatments such as coating or painting to enhance corrosion resistance.

Cast Iron

Cast iron is commonly used for flanges because it is durable, more cost-effective, and robust under high heat and pressure. For example, many cast iron pump housings, including their flanges, are made using grades such as grey cast iron or ductile iron. This is because they can endure the harsh temperature and vibration during engine operation.

Aluminum

Aluminum is best suited for producing flanges with lightweight properties and good thermal conductivity, which also helps to reduce overall engine weight and improve heat dissipation. This material is commonly used in aftermarket or performance-oriented water pump housings/flanges. Aluminum flanges are durable where corrosion is more likely, because the material naturally forms a protective oxide layer that resists moisture.

Powder Metallurgy materials

Powder metallurgy allowswater pump flanges to be produced with near-net shape and high dimensional accuracy. Powder metal materials, such as iron-based or stainless-steel powders, are commonly used for their strength and wear resistance. Additional treatments like steam oxidation can further enhance surface hardness and corrosion resistance.

Manufacturing Methods

Casting

Many flanges are formed by pouring molten metal (e.g., cast iron, aluminum alloy) into molds. This gives room for production flexibility for different geometries and sizes; it also allows for the formation of bolt holes and other surface features. Cast components are generally faced with the potential defects from high porosity, hence questionable structural integrity; this should be considered when choosing flange production methods.

Machining

After casting or forming, machining operations (turning, drilling, milling) are done using lathes, CNC machines, or mills to ensure precision in bolt-hole placement and dimensional accuracy. The machining processes ensure that the seal and alignment are reliable, making the flange suitable for specialized and/or high-pressure applications.

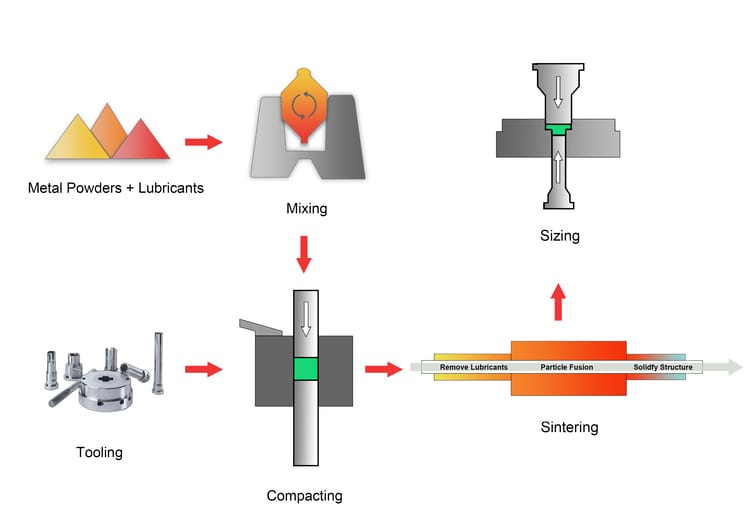

Powder Metallurgy

Some manufacturers produce water pump flanges through powder metallurgy process by sintering compacted metal powder. This method goes through about four stages: the metal powder is mixed, compacted under high pressure, and then sintered under controlled atmospheric conditions. The sintered product undergoes secondary surface treatments such as dacromet, steam treatment, or electroplating before the final water pump flange product is finished.

Applications of Water Pump Flanges

Some automotives that have internal combustion engines that use liquid coolants must have a water pump flange to connect the water pump to the engine, which prevents overheating:

Passenger Cars & SUVs

The water pump flange is used to attach the water pump to the engine block. It helps to connect the timing belt-driven water pumps.

Trucks and Buses

A water pump assembly with powerful cooling systems is used in trucks and buses, and they also come with water pump flanges that provide proper coolant circulation to curb overheating.

Maintenance and Troubleshooting

- Regularly inspect flange joints for signs of coolant leakage, rust, or corrosion. Flange bolts may loosen from vibration over time; check to tighten them.

- It is of utmost importance to use the right gasket material; check and replace gaskets or seals if flattened, hardened, or damaged.

- If flange faces are warped or damaged, you need to replace the water pump flange.

- Make sure to use safety gear when working and ensure the engine is cool; disconnect the battery to avoid accidental starts and properly clean spills to prevent slipping.

Benefits of Using the Right Flange

Leak Prevention

Choosing the right flange and gasket with proper installation helps avoid coolant loss, overheating, and engine damage.

Extended Pump Life

A secure flange ensures less vibration, better alignment, less wear on the bearings and seals in the pump, which leads to pump longevity.

Easier Maintenance and Repair

Flanges make disassembling easier during servicing or repair; you can replace the pump or gasket without cutting pipes or damaging adjacent components.

BLUE is a specialized powder metallurgy manufacturer with over 20 years of experience. We provide a full range of automotive components, including water pump flanges & pulleys.

You can explore our Water Pump Flange SHOP to select from standard parts or download our product list for details. We also deliver customized powder metallurgy solutions tailored to your specific applications.

FAQ

How Often Should a Water Pump Flange be Checked or Replaced in a Car?

The water pump flange comes hand-in-hand with the water pump; therefore, it should be replaced every time you replace the water pump or during a major cooling system service. Regular inspections of the water pump should also extend to the flange; check during belt replacements, or if you notice coolant leaks, noise, or overheating. Conducting regular visual inspections every few thousand miles in addition to following the manufacturer’s manual also helps.