Shock Absorber Piston

BLUE is a professional manufacturer of shock absorber pistons, all produced with tight tolerances of ±0.01 mm. Our components are widely used in automotive, motorcycle, and off-road suspension systems.

What is a Shock Absorber Piston?

A shock absorber piston is an internal part inside the damper that moves through hydraulic fluid to generate damping force. This piston is responsible for controlling fluid flow through its precisely machined orifices or holes that allow controlled passage of hydraulic fluid. Piston itself moves through the hydraulic fluid within the shock absorber to regulate resistance as the suspension compresses and rebounds.

Shock absorber pistons are generally produced from aluminum alloys or sintered iron. Aluminum alloys provide low weight and good heat dissipation, while sintered iron offers high strength and wear resistance for heavy-duty use.

How does the Shock Absorber Piston Work?

The role of shock absorber piston is to control how a vehicle’s suspension reacts to bumps and road irregularities by providing damping resistance. The piston moves up and down with the shock absorber cylinder when the vehicle encounters a bump or dip.

This forces hydraulic fluid to pass through small orifices in the piston, allowing only a controlled amount of fluid to pass at a time. As a result, the piston’s movement slows down and regulates how quickly the suspension compresses or rebounds. The energy generated during this process is dissipated as heat, preventing excessive bouncing and ensuring the tires remain firmly in contact with the road.

Advantages of BLUE Shock Absorber Pistons

BLUE’s shock absorber pistons are manufactured under the strict standards of ISO 9001:2015 and IATF 16949:2016.

Our shock absorber pistons are manufactured using powder metallurgy, achieving tight tolerances and highly consistent quality.

BLUE offers a variety of surface treatment processes, including steam treatment, machining, oil impregnation, electroplating, and Dacromet.

Download Shock Absorber Part Product List

The following is a list of our standard shock absorber parts, including shock absorber guide, shock absorber piston, shock absorber valve body and seat.

Shock Absorber Guide

Shock absorber guides are basic components used in the suspension system of vehicles to support and align the shock absorber.

Shock Absorber Piston

A shock absorber piston is attached to the rod inside the shock absorber and moves up and down within the shock absorber cylinder.

Shock Absorber Valves Body

Shock absorber valve body controls fluid flow during compression and rebound to adjust suspension resistance.

Shock Absorber Valve Seat

A shock absorber valve is the part of a shock absorber that controls the flow of hydraulic fluid between its chambers.

Need Shock Absorber Parts?

Types of Shock Absorber Pistons

Hydraulic Shock Pistons

Hydraulic shock pistons are the primary component of a hydraulic shock absorber, where the cylinder is filled with hydraulic fluid. Pistons move through this fluid, creating resistance that dampens the motion. Such piston contains a series of valves, often shim stacks or orifices that restrict oil flow.

Additionally, these valves are critical in determining the damping characteristics during both compression and rebound strokes. The size and number of orifices directly influence the damping rate. Hydraulic shock absorber pistons are fitted with seals to prevent oil bypass around their outer diameter, ensuring that all displaced fluid passes through the valving. These pistons are present in standard passenger vehicles.

Gas-Charged Shock Pistons / Gas-Pressurized Designs

These pistons are present within gas-charged shock absorbers, which incorporate a low-pressure nitrogen gas charge into the hydraulic system. In mono-tube designs, a floating piston separates the oil from the gas, preventing aeration. This floating piston moves freely within the shock body, compressing the gas as the main piston displaces oil. This design prevents the oil from mixing with air/gas, thereby eliminating cavitation and maintaining consistent damping.

Adjustable / Electronically Controlled Pistons

Electronically controlled shock absorbers utilize sensors and electronic valves to adjust the damping characteristics in real-time. The electronically controlled piston assembly includes electronically actuated valves, such as solenoids or stepper motors, that can rapidly change the size of the oil passages or the stiffness of the valving. These valves are controlled by a central ECU based on sensor inputs, either wheel speed, steering angle, or vehicle load, allowing for real-time, adaptive damping adjustments.

Manufacturing Process of Shock Absorber Piston

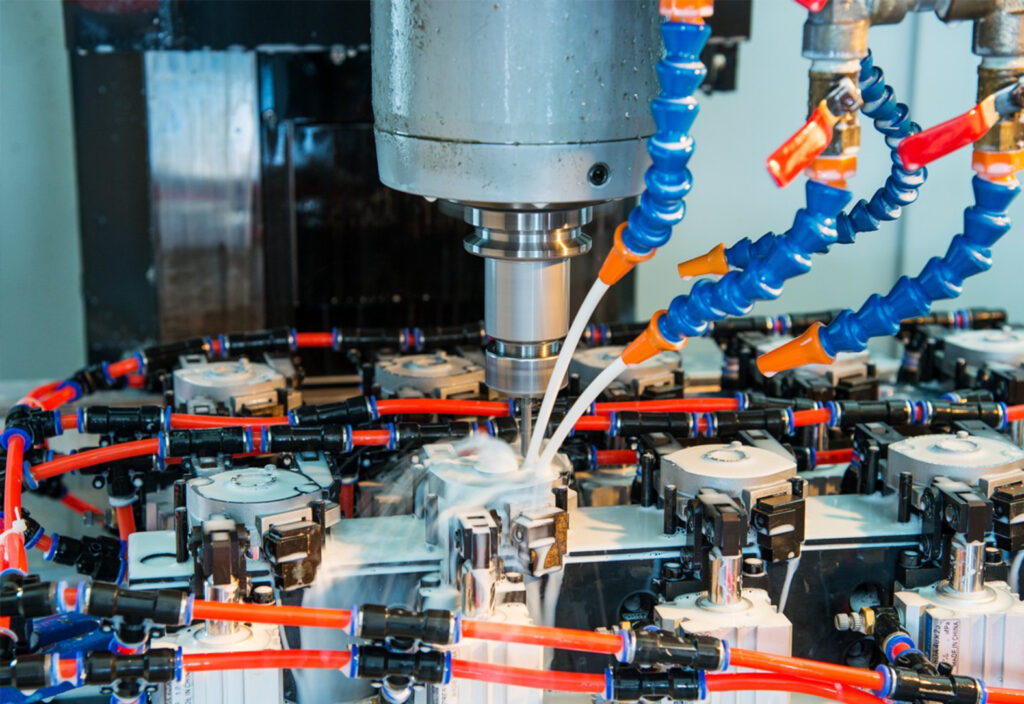

CNC Machining

Manufacturers use CNC machining to produce shock absorber pistons from solid metal stock, achieving excellent dimensional precision and surface integrity. This method becomes inefficient for mass production due to high material removal rates and extended cycle times.

Powder Metallurgy

Shock absorber pistons produced by powder metallurgy process begin with metal powder compacted into a die cavity to achieve the desired shape. Then this green compact is heated below its melting point to bond the particles metallurgically, achieving strength and dimensional stability.

A study showed that the manufacturing of shock absorber pistons through powder metallurgy using Fe-Cu alloy steels shows exceptional properties, including:

- PM enables manufacturers to produce pistons of desired strength by controlling their porosity. For example, lower porosity shock absorbers, such as those with 10% porosity, result in higher density (~7.0 g/cm 3).

- At approximately 90% of theoretical density (~7.0 g/cm³), Fe–Cu powder metallurgy alloys typically exhibit ultimate tensile strengths in the range of 300–430 MPa in the as-sintered condition

- These pistons showed enhanced hardness and impact resistance, ensuring durability and stable performance under cyclic loads.

- With powder metallurgy, manufacturers can achieve tight tolerances (±0.01 mm) and fine surface finishes.

Metal Injection Molding

Metal Injection Molding (MIM) combines the versatility of plastic injection molding with the strength of sintered metal. In this method, the manufacturer uses ultrafine metal powders, which are mixed with a polymer binder. Now this feed is injected into molds to achieve near-net shape components with minimal post-processing. After molding the green part is subjected to sintering where the binder is removed, the final component obtained has high density and strength. MIM offers exceptional properties to shock absorbers. The key characteristics are summarized below:

| Property / Characteristic | Description |

|---|---|

| High Density | Achieves up to 99% of the density of wrought materials. |

| Controlled Shrinkage | Predictable 15–25% shrinkage during debinding and sintering with uniform density. |

| Dimensional Accuracy | As-sintered tolerance of approximately ±0.3% of nominal dimensions with excellent surface finish. |

| Material Flexibility | Stainless steels, low-alloy steels, superalloys, high-speed steels, hard metals, and magnetic alloys. |

Damping Curve-Based Piston Designs

Linear Pistons

These pistons provide a near-linear damping response over a limited velocity range. As a result, they offer a consistent and predictable response across a wide range of suspension speeds.

Design and Characteristics of Linear Piston

- Flat Faces: Linear pistons typically have perfectly flat faces where the valve disks (shim stacks) are seated.

- Pyramid Stacks: To achieve linear performance, these pistons commonly utilize pyramid stacks of valve disks, where the disks decrease in diameter. This configuration allows for a consistent increase in damping force as oil flow increases.

- Sufficient Bleed Holes: The piston incorporates adequately sized bleed holes to allow oil flow, contributing to the linear response. The damping force is primarily generated by the resistance of oil flowing through these fixed orifices and the deflection of the shim stack.

Digressive Pistons

Digressive pistons are designed to offer firm damping at low shaft speeds while remaining softer at higher speeds. Digressive behavior results from preloaded shim stacks or blow-off valves that open at a set pressure, reducing the damping slope at higher piston speeds. This setup enhances control during low-speed body motions such as braking, cornering, or acceleration.

Progressive Pistons

Progressive pistons deliver a damping force that increases more rapidly with piston velocity or pressure differential. It ensures a smooth ride at low speed while offering firm resistance at high speed or high suspension movements. As a result, it effectively prevents bottoming out and enhances vehicle control under demanding conditions. The progressive behavior is mainly due to stiff valve stacks and restrictive orifice geometry; the bleed path only affects low-speed damping and is not the cause of progressivity.

Applications of Shock Absorber Pistons

Passenger Cars

Passenger-vehicle shocks often use linear, digressive, or progressive pistons depending on how aggressively the vehicle is tuned. For instance, Luxury vehicles often employ digressive or adaptive damping valves to provide a soft initial response and stable control at higher speeds However, sportier models usually employ digressive pistons for enhanced body control during aggressive driving maneuvers.

Motorcycles

Motorcycle suspension systems typically incorporate a piston, such as in forks or rear shocks, combined with springs. The piston modulates oscillations from road irregularities, isolating the rider and improving handling.

Off-road Vehicles

Often, off-road shocks feature robust pistons with progressive or hybrid valving schemes. These designs are engineered to handle severe conditions, such as large impacts, high-speed washboard sections, and prolonged rough terrain, without failure.