Sintered Water Pump Flange From China

BLUE offers 100+ standard water pump flanges, perfectly suited for your engine, with no mold fees. Compatible with Audi, VW, Toyota, Mazda, Jaguar, Ford, Kia, Suzuki, etc.

Why Choose BLUE?

We have established ourselves as a trusted supplier of water pump flanges, providing free mold design service, free samples, fast shipping, and competitive prices.

BLUE High Quality Standards

BLUE assurethe quality of your water pump flanges with an ISO 9001:2015 certified quality management system. Free samples are available for testing.

Standard Water Pump Flange Shop

BLUE has a full range of standard flanges in stock for fast delivery. Visit our standard parts shop to find the exact match for your applications.

Free Mold Design Service

With over 20 years of expertise in mold design, BLUE offers free, high-precision mold design services to meet your customized needs. Let our experience work for you!

What Is a Water Pump Flange ?

A water pump flange is a mechanical installation part that links the water pump to an engine, housing or plumbing connection. It offers a secure interface for the pump shaft or impeller and maintains the seal that prevents coolant from leaking through the system.

In automotive and machine applications, the flange usually has been machined to precision tolerances and is constructed of material such as cast iron, steel, aluminium or a powder metallurgy alloy in order to provide high strength and dimensional stability. This generally has bolt holes, a hub or bore for the pump shaft and a surface on which seals such as gaskets or O-rings are to be sealed against.

The water pump flange is fitted in position and provides a stable coolant flow with no leaks while connecting the pump to bearing structure to facilitate effective thermal management across engines and industrial cooling systems.

How Water Pump Flanges are Made by Powder Metallurgy?

Water pump flange production begins with mixing iron-based powders such as FC-0205, FC-0208, or FN-0205 with zinc stearate or lithium stearate. These binders improve powder flow and compaction performance. The mixed powders are subsequently pressed into a precision multilevel die at 400–800 MPa, resulting in formation of the green compact (the geometry of flanges, position the bolts and surface for sealing).

For the ferrous material, the green compact is sintered in a controlled atmosphere furnace at approximately 1120 °C. Under the sintering process, solid state diffusion bonds the particles and density, strength and design stability are gained that turns the compact into a fully functioning water pump flange.

Sizing and machining are performed after sintering to final tolerances and finish. Frequent surface treatment such as steaming, Dacromet coating and electroplating can be used to improve anti corrosion ability of fastener.

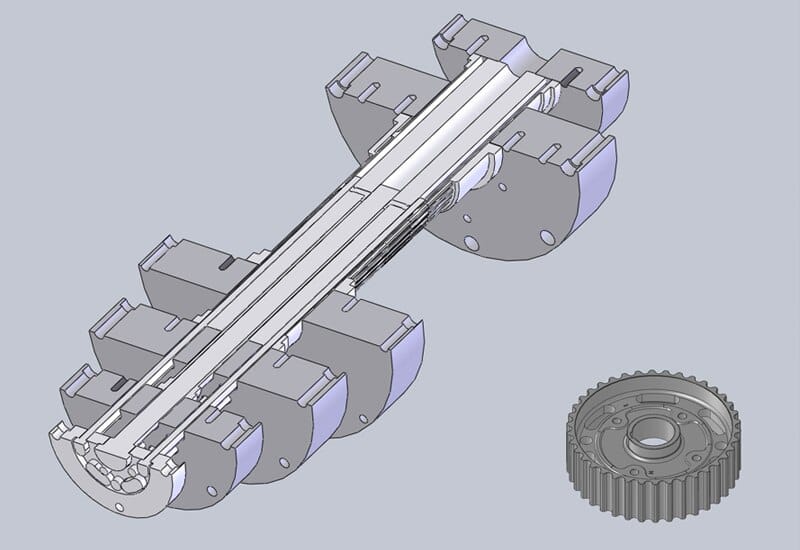

BLUE Powder Metallurgy Water Pump Pulley

BLUE provides a variety of flanges for your water pump, covering a wide range of vehicle engine models.

Water Pump Flange

BLUE's high-quality water pump flanges, after heat treatment, offer excellent corrosion resistance, durability, and enhanced hardness and strength.

Auto Water Pump Flange

BLUE auto water pump flange uses iron-based powder as raw material, which has uniform density and good mechanical properties after sintering process.

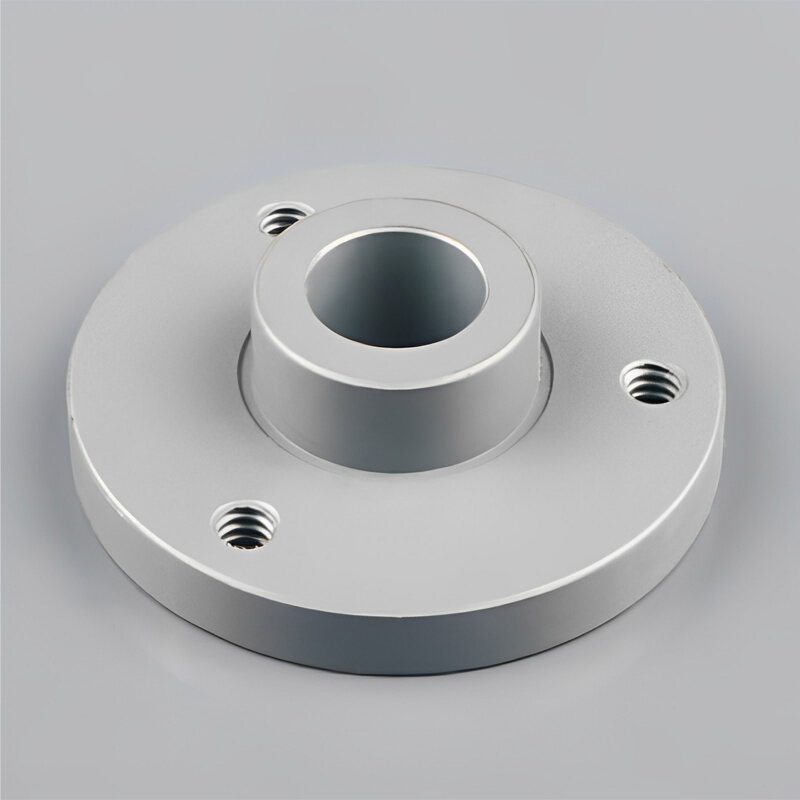

Mini Water Pump Pulley

BLUE's mini water pump flanges are suitable for compact engine water pumps and provide reliable sealing function.

Powder Metal Water Pump Flange

Our powder metal water pump flanges have a core hole tolerance within ±0.015mm and smooth burr-free threads to ensure secure installation.

Sintered Water Pump Flange

Our sintered water pump flanges are made of MPIF standard 35 FC-0208 as raw material, which has good mechanical strength and durability after sintering.

Powdered Metallurgy Water Pump Flange

BLUE powder metallurgy water pump flanges allow a variety of surface treatment processes to improve performance, including Dacromet and electroplating

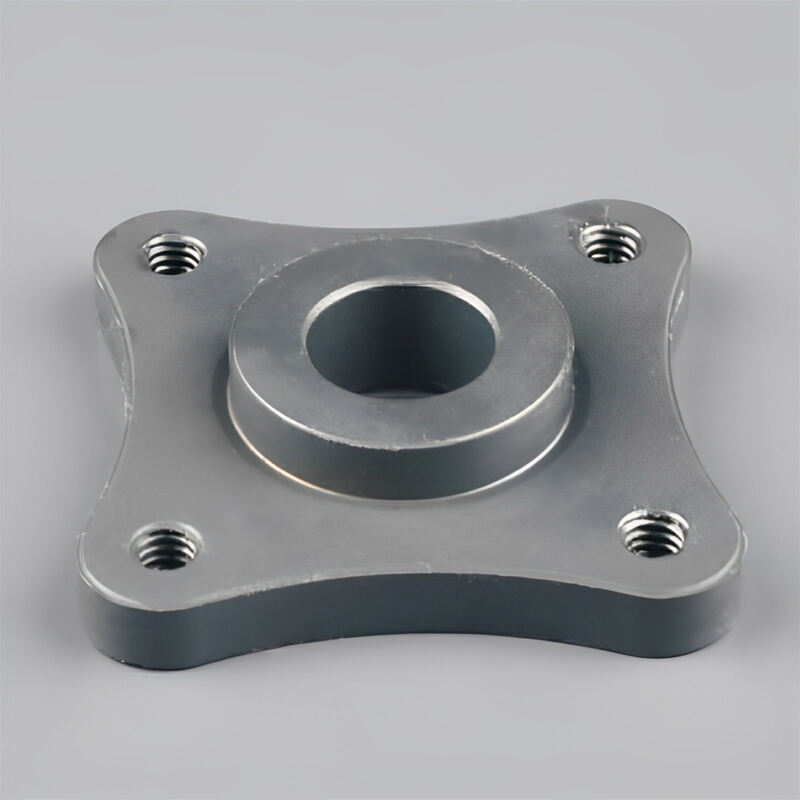

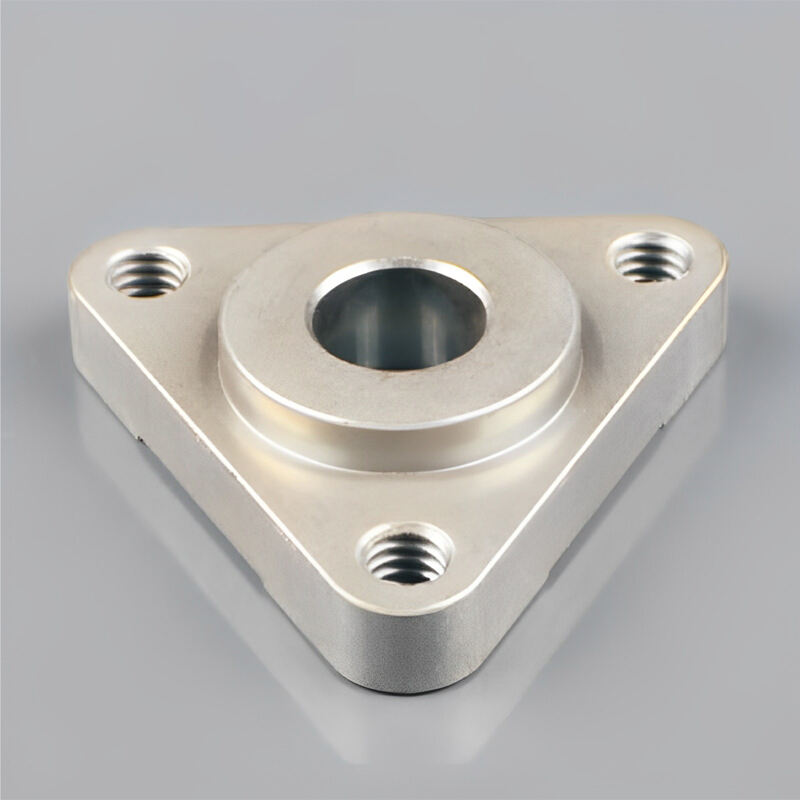

Powdered Metal Water Pump Flange

Our powdered metal water pump flanges come in a variety of styles, including round, square, triangular

Sintered Metal Water Pump Flange

BLUE sintered metal water pump flanges can reach a hardness of more than 65HRB after steam treatment, which has a long service life.

R53 Water Pump Flange

R53 water pump flange is the basic part of the automobile engine water pump, which is used to drive the water pump impeller to rotate.

BLUE Water Pump Flange Features

BLUE water pump flanges are manufactured in compliance with IATF 16949:2016 standards.

Our sintered water pump flanges are available in many types, including round, rounded square, and triangular, suitable for many types of automotive water pumps.

BLUE powder metallurgy flanges have high dimensional accuracy within ±0.015mm, ensuring precise connection..

The threads of our water pump flangs are precisely processed with a smooth surface and no burrs, making them easy to install.

Standard Water Pump Flange

With over 20 years of expertise in powder metallurgy, BLUE provides a wide range of standard parts with no tooling fees.

Our standard sintered water pump flanges are compatible with a variety of automotive engines, including GTE, TDCi, Carens, TDI, DCI, TSI, and more.

These standard flanges are available in various sizes, shapes, and surface treatments.

Download our product list for free by clicking the link below.

Sintered Water Pump Flanges Benefits

High Raw Material Utilization

Sintered flanges are compacted from metal powder to achieve a net shape, reducing the need for further machining process.

Tight Tolerance

The tolerance of water pump flange can reach between IT6 to IT7 after sizing.

Cost-effective in Mass Production

Powder metallurgy water pump flanges are cost-effective in mass production due to fewer processes and higher material utilization.

Batch to Batch Quality Consistency

Water pump flanges have good quality consistency between different batches.

Wide Range of Surface Treatments

Dacromet

Dacromet is a water-based, chrome-free coating made from zinc, aluminum flakes, and a binder. Water pump flanges are cleaned, coated by dipping or spraying, then cured to form a protective layer.

Anti-rust oil

Sintered flanges can be oil-soaked to prevent rust for up to one year.

Galvanizing

Sintered flanges have pores inside, which need to be filled before electroplating, and then a layer of zinc is applied by electroplating.

Custom Water Pump Flange Specifications

The following table shows BLUE’s production capabilities for water pump flanges, including density, hardness, tolerance and diameter range, surface treatment, etc.

| Attribute | Value |

|---|---|

| Material | MPIF Standard 35 FC-0205. FC-0208, FN-0205, FD-0208 |

| Density | 6.6-7.0g/cm3 |

| Hardness | 65-90 HRB |

| Surface Treatment | Steam Treatment, Dacromet, Electroplating |

| Diameter | Max. 350mm |

| Length | Max. 200mm |

| Tolerance | ±0.015 mm |