In manufacturing, vacuum sintering is a vital process, especially when it comes to powder metallurgy and material science. This method is a high-temperature heat treatment process carried out in a vacuum environment to densify powder metallurgy parts without oxidation or contamination. It is commonly used for materials that are sensitive to air, such as stainless steels, tungsten alloys, titanium, and ceramics.

In this article, we’ll explore vacuum sintering: what it is, its working principle, its benefits, and its real-world applications.

Contents

What Is Vacuum Sintering?

Vacuum sintering can be defined as a specialized thermal process where powdered materials are compacted and then heated under vacuum conditions to a temperature just below their melting point. The idea of using a vacuum is to remove oxygen, which suppresses harmful reactions such as oxidation, thereby enabling atoms to diffuse efficiently and fill microscopic pores within the material. In addition, this prevents contamination and results in a dense, strong, and highly pure final product.

Because it delivers superior mechanical properties, vacuum sintering is the preferred choice for manufacturing high-precision parts from metals and ceramics with very high melting points.

Vacuum Sintering Furnace

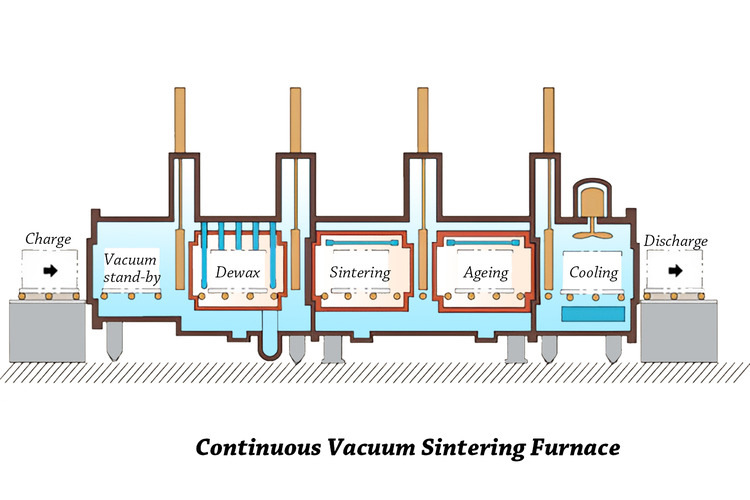

The vacuum sintering furnace is the heart of this process because it provides the controlled atmosphere needed for high-quality sintering and production.

Working Principle

The furnace creates a vacuum chamber by removing gases like oxygen, nitrogen, and water vapor to prevent oxidation. The material to be sintered is heated to high temperatures, enabling atomic diffusion and the movement of grain boundaries. The result is a dense solid with enhanced mechanical properties.

Key Features

The general temperature range for a vacuum sintering furnace is 1100°C–2000°C; however, some furnaces range up to 2400oC and even 3000oC, depending on the material.

The components include:

- The vacuum chamber where the sintering takes place.

- Heating elements such as tungsten and graphite which are responsible for providing the heat needed for sintering.

- Vacuum pumps with different vacuum levels and pumping speeds are used accordingly to create the vacuum in the chamber.

- Loading system for loading and removing the material to be sintered; it could be manually operated or automated.

- Temperature control system for controlling the sintering temperature, heating, and cooling rate of the process.

- Water cooling system to cool the furnace and vacuum pump.

Vacuum Sintering Process

Debinding

The first important step in vacuum sintering is to remove any binders used to hold the powder particles together, that is, removing the primary binder from the molded component. This step is done via evaporation following degradation, or with the use of a solvent.

In summary, a gas is used to degrade the binder into small molecules that can be evaporated via a chemical reaction. This is done by heating material to 200-600 °C until the binders are decomposed into vapour. The vapour is taken out of the chamber through gas flow and surface-connected pores, and the debinding process is complete.

Sintering

The debinded part is placed in the chamber and heated to a temperature just below its melting point under a vacuum. During sintering process, particles bond through diffusion, porosity decreases, and impurities are removed, resulting in a pure, dense, and strong material.

Cooling

The next step after sintering is to gradually cool the sinter in the vacuum furnace under controlled conditions. Controlled cooling prevents oxidation, thermal stresses, and deformation.

Vacuum Sintering Materials

Vacuum sintering is ideal for materials that are difficult to process using conventional methods. This is because of the need to prevent oxidation and contamination to produce superior quality and high-performance components. These materials include:

Tungsten and Molybdenum.

These are known for their high melting points and resistance to extreme conditions. The vacuum sintering process enhances the prevention of oxidation and promotes atomic diffusion.

Titanium Alloys

These are used in aerospace and medical applications. It is important to keep the material surface clean to avoid nitriding and oxidation during the process.

Advanced Ceramics and Composites

They offer excellent hardness and wear resistance. Vacuum sintering prevents reduction or excessive oxidation and controls grain growth when using these materials.

Vacuum Sintering: Advantages and Limitations

Advantages

- This method eliminates oxidation and contamination, thereby ensuring high material purity.

- It produces parts high in density and strength, with superior mechanical properties.

- It enhances surface finish by preventing unwanted reactions.

- It is ideal for processing reactive or refractory materials that are naturally challenging to sinter otherwise.

Limitations

- This method poses a high operational cost because vacuum furnaces are expensive to purchase and maintain.

- It is energy-intensive due to high temperature and vacuum requirements.

Applications of Vacuum Sintering

Vacuum sintering is widely applied in industries where precision and material integrity are of utmost importance:

Powder Metallurgy Parts

For conventional powder metallurgy parts, materials that are sensitive to oxidation or require high density, such as stainless steels and titanium alloys, are often vacuum-sintered. The oxygen-free atmosphere allows higher sintering temperatures and results in parts with high density, low impurity levels, and superior quality.

Metal Injection Molded (MIM) Parts

Vacuum sintering is also a common method for metal injection molded parts, particularly for materials such as stainless steel, tool steel, and titanium alloys that are sensitive to oxidation or require high density. The vacuum environment helps remove impurities, prevents oxidation, and improves part strength, surface quality, and dimensional stability.

Ceramic Parts

High-melting-point ceramics typically demand sintering temperatures ranging from 1600 °C to 2000 °C. In conventional atmosphere furnaces, residual oxygen or process gases quickly oxidize molybdenum or graphite heaters, disrupting uniform heating, damaging equipment, and contaminating the compact. A vacuum furnace prevents these reactions, reaches the target temperature more efficiently, and yields dense, clean sintered ceramic parts with fine grains and excellent mechanical and thermal properties.

Additive Manufacturing (AM) Parts

It is important to process additive manufacturing in collaboration with vacuum sintering because it ensures that the required hardness, size, and density are achieved. Additionally, it mitigates the need for post-machining processes and prevents the production of faulty parts. This makes it ideal for post-processing of 3D-printed metal components such as turbine hubs in automotive applications, aerospace engine parts, prosthetics, and medical implants.

Vacuum Sintering vs. Other Sintering Methods

| Method | Atmosphere | Cost | Properties of Final Part | Applications |

|---|---|---|---|---|

| Vacuum Sintering | Vacuum (no oxygen) | High | High purity, high density | Aerospace, medical, electronics |

| Conventional Sintering | Atmospheric gas | Low | Lower purity, oxidation risk | General powder metallurgy |

| Hot Isostatic Pressing (HIP) | High pressure + inert gas | Very High | Extremely dense, defect-free | Critical aerospace/medical parts |

| Spark Plasma Sintering (SPS) | Pulsed DC + pressure | High | Ultra-fast sintering, fine microstructure | Research, advanced ceramics |

FAQ

How Does Vacuum Sintering Affect Grain Growth in Materials?

Vacuum sintering minimizes unwanted grain growth and enhances densification because the process is tightly controlled and free from contaminants via oxygen vacancies. This results in a fine and uniform microstructure that enhances the mechanical properties of the final component.

Can Vacuum Sintering Be Combined with Other Techniques for Better Results?

Yes. Vacuum sintering is sometimes combined with hot isostatic pressing (HIP) or rapid cooling techniques to further improve density and eliminate porosity in high-performance parts.

How Does the Vacuum Level Influence the Quality of Sintered Parts?

The quality of sintered parts strongly depends on the vacuum level. Ultra-high vacuum levels like 10⁻3 Pa reduce oxygen content to nearly zero, preventing secondary oxidation, residual microcracks, and segregation at the particle boundaries. Thus, improving the mechanical performance of the end product.