Titanium Metal Injection Molding (TIMIM)

BLUE has more than 10 years of experience in titanium metal injection molding. Our titanium MIM parts have the advantages of high quality consistency, good durability, tight tolerance and good strength.

Why Choose BLUE?

BLUE is an ISO 9001:2015 certified metal injection molding and powder metallurgy supplier. We provide standard parts without tooling fees.

BLUE High Quality Standards

BLUE assures your product quality with ISO 9001:2015 certified quality management system. We provide a one-year warranty on your metal injection molding products.

Standard Parts Shop

BLUE has a wide range of standard metal injection molding parts in stock for fast delivery. Visit our standard parts shop to find the exact match for your applications.

OEM/ODM Services

Using advanced equipment, we provides free mold design based on your drawing and offers assistance with your cotomized product processing.

What is Titanium Injection Molding?

Titanium Injection Molding (TiMIM) is a metal injection molding process that uses fine titanium powder mixed with polymer binders to form complex, near-net-shape components. The molded “green part” is debound and then sintered in a controlled atmosphere or vacuum furnace, where the titanium particles bond metallurgically and achieve high density.

TiMIM allows manufacturers to produce intricate titanium parts that would be difficult, wasteful, or expensive to machine from wrought stock. The process maintains titanium’s well-known advantages such as high strength-to-weight ratio, corrosion resistance, and biocompatibility.

Properties of Titanium

Titanium has a high strength-to-weight ratio, making it ideal for weight-sensitive applications such as aerospace components.

Titanium has a stable oxide layer (TiO₂) on the surface, which is extremely resistant to corrosion in seawater, chlorine, acids and body fluids.

Titanium and its alloys have good biocompatibility, are non-toxic, and will not be rejected by the human body.

Pure titanium has a melting point of 1,668°C (3,034°F) and is suitable for components in high-temperature environments (such as turbine blades, exhaust systems).

Benefits of TIMIM

Titanium metal injection molding parts are near net shape, eliminating secondary machining costs.

For titanium and its alloys, casting is difficult, but metal injection molding allows high design flexibility.

MIM mass production has price advantages compared to CNC machining and additive manufacturing.

Metal injection molding material utilization can reach more than 95%, saving resources and costs.

Applications of Titanium MIM

Medical: Titanium Metal Injection Molding (Ti-MIM) is widely used to produce medical implants such as screws, plates, spinal devices, artificial joints, oral implants.

Surgical tools: Metal injection molding enables the production of surgical tools with complex features to meet the requirements of modern medical care.

Consumer Electronics: Titanium injection molding enables the production of small, precise components such as smartphone frames, watch casings, and lens mounts.

Aerospace and Defense: In the aerospace field, Ti-MIM is used to manufacture lightweight and high-strength components.

Custom MIM Parts Capabilities

The following are BLUE’s custom metal injection molding titanium parts capabilities, including part size, weight, wall thickness, surface roughness, etc.

| Attribute | Value |

|---|---|

| Part Mass | 0.2 to 100g |

| Size | Diameter 1-30 mm. |

| Wall thickness | 0.5-12.5 mm |

| Torlances | ±0.5% |

| Density | 95%-99% |

| Surface Finish | Ra 1 μm |

Metal Injection Molding Parts Gallery

Below are some of the metal injection molded parts we have produced.

TI MIM Parts Manufacturing Process

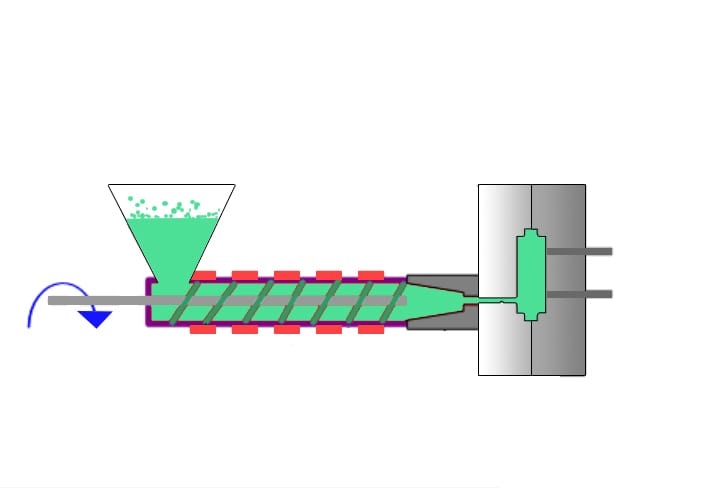

The following is the basic process of titanium metal injection molding, including mixing, injection, debinding and sintering.

Designing

Ti-MIM part design must consider powder characteristics, binder compatibility, shrinkage rate, wall thickness, and final mechanical property requirements.

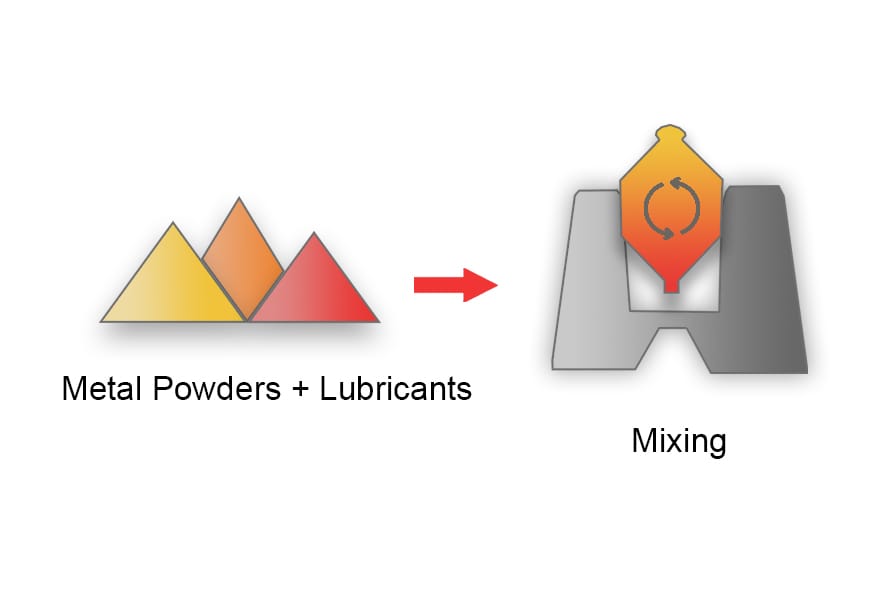

Mixing

Titanium powder and binder are mixed in about 60:40 ratio to create feedstock. Binder improves flowability and ensures uniform particle distribution.

Injecting

The feedstock pellets are melted and injected into precision steel molds to form green parts, which are oversized to compensate for shrinkage.

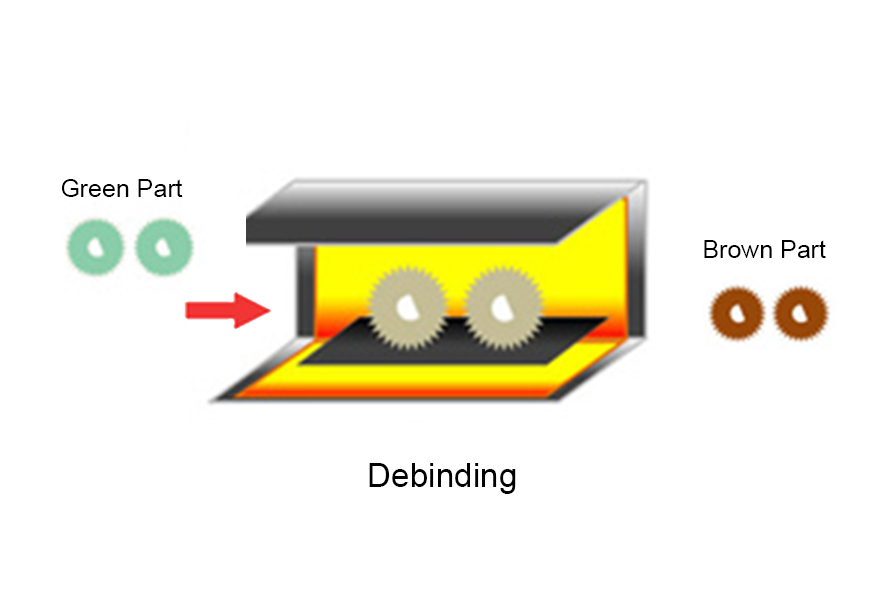

Debinding

Binder is removed from the green parts by solvent or thermal debinding. After this step, fragile brown parts with the final geometry remain.

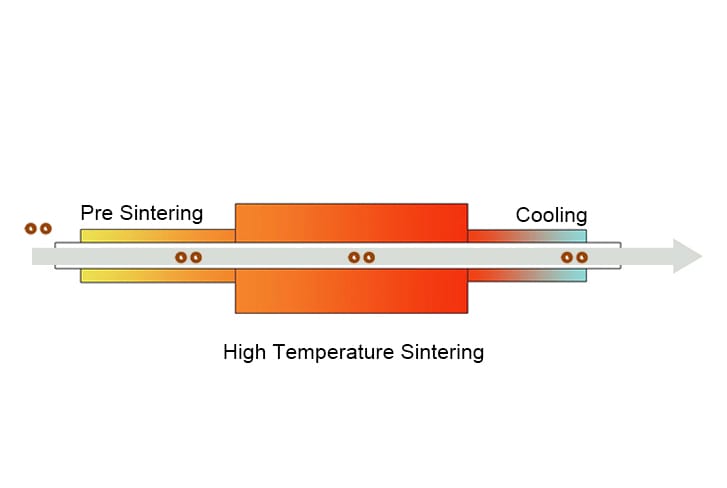

Sintering

Sintering heats the components to a temperature below its melting point in a controlled atmosphere to obtain the desired mechanical properties.

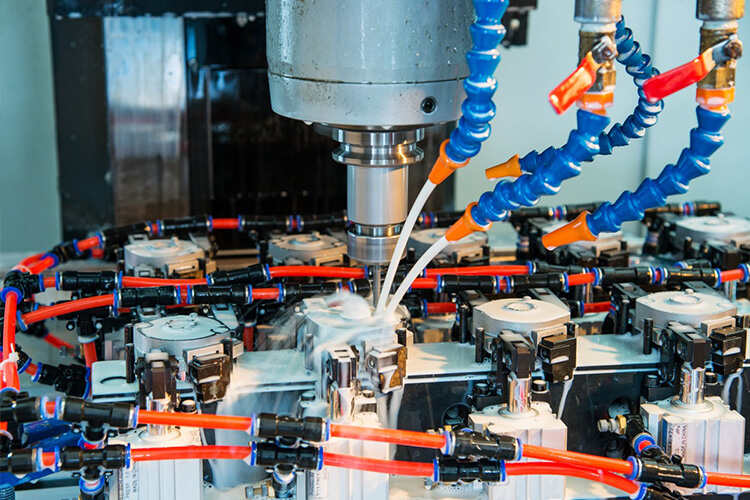

Secondary Operations

After sintering, parts may undergo hot isostatic pressing, heat treatment, or machining and plating to improve surface finish and mechanical properties.