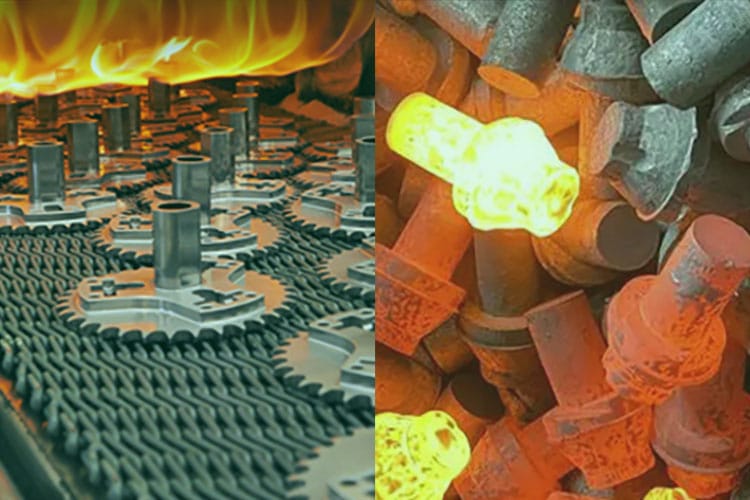

Powder Metal Parts VS. Forged Parts

Powder metallurgy forms components through die compaction and sintering at temperatures below the metal’s melting point, while forging deforms heated or cold metal under high pressure to achieve the desired profiles.

PM is better suited for producing complex-shaped parts with controlled porosity, while forging is ideal for simple shapes requiring high strength and durability.