Sintered Stainless Steel Filter - BLUE

BLUE’s sintered stainless steel filter is your reliable filter component, with accurate and high filtering rating, long service life, high temperature, high pressure and corrosion resistance.

A Wide Variety of Sintered Stainless Steel Filters

BLUE has more than ten years of experience in the design and production of sintered filters. We are able to manufacture a wide variety of sintered stainless steel filters and provide customized services according to your needs.

Porous Stainless Steel Disc

The porous stainless steel disc is made of stainless steel powder as raw material, with uniform density and high filtration efficiency.

Sintered Stainless Steel Filter Element

Sintered stainless steel filters have high filtration accuracy and excellent high temperature resistance.

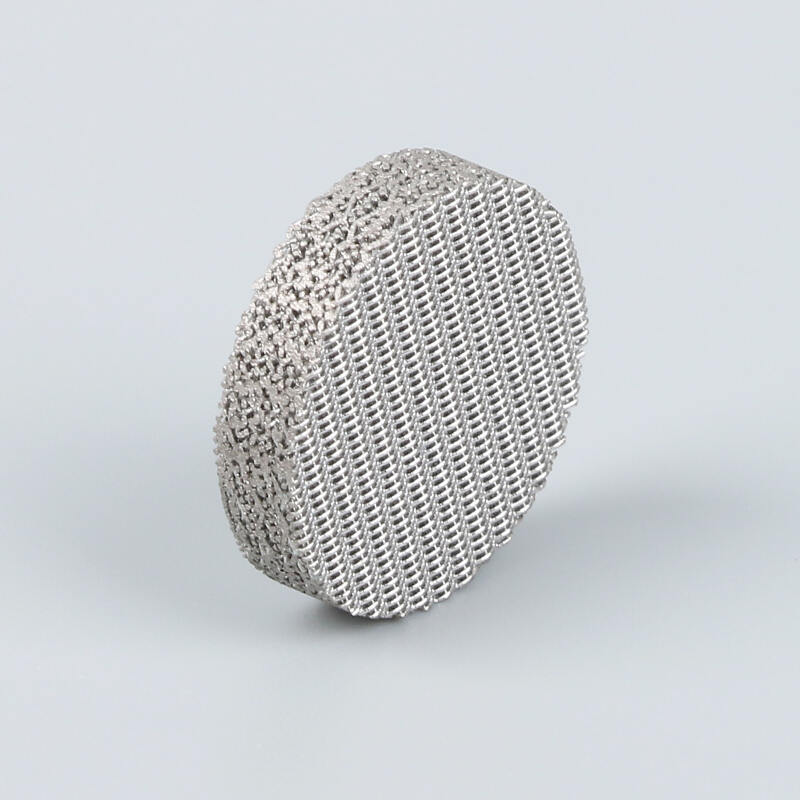

Stainless Steel Wire Mesh Filter

Stainless steel wire mesh filters have uniform pore size and high filtration accuracy, so they have high filtration efficiency.

Sintered Stainless Steel Sparger

BLUE sintered metal spargers have uniform pores and are suitable for diffusing oxygen, carbon dioxide and nitrogen.

Stainless Steel Pneumatic Muffler

Stainless steel pneumatic mufflers not only effectively reduce noise but also filter suspended matter and particles from the gas.

Stainless Steel Breather Vent

Stainless steel breather vent is small in size and has the ability to reduce noise and control gas or liquid flow.

Sintered Stainless Steel Filter Plate

Sintered stainless steel filter plate has uniform pores, filtration efficiency up to 99% and good durability and strength.

Sintered Stainless Steel Tube

Sintered stainless steel tubes have excellent mechanical strength and maintain their structural integrity under pressure, ensuring consistent filtration performance.

Porous Stainless Steel Filter

Our porous stainless steel filters are available with a porosity range of 25-45%, a maximum diameter of 2000mm, and a thickness of up to 30mm.

Why Choose BLUE?

BLUE offers you high quality sintered stainless steel filters, backed by advanced production machines, stringent quality control, and free samples—assuring excellent quality throughout our entire product range.

BLUE Quality Standards

BLUE assures your product quality with ISO 9001:2015 certified quality management system. We provide a one-year warranty on our sintered porous stainless steel filters.

Standard SS Filter Shop

BLUE offers a wide range of standard sintered SS filters in stock for quick delivery. Visit our shop to pick up what you need.

Download SS Filter Product List

Discover BLUE’s full range of powder metallurgy standard sintered stainless steel filters. Download our free product list to find the exact match for your requirements.

BLUE's Sintered Stainless Steel Filters Advantages

- BLUE’s stainless steel filters have extremely high filtration rating, up to 0.5μm or even 0.2μm.

- We have a variety of sintered stainless steel filters, including sintered stainless steel discs, sintered stainless steel sheets, sintered stainless steel tubes, sintered stainless steel pneumatic silencers, and sintered stainless steel breather vents.

- Free samples are available upon request before placing a formal order.

- We also provide free design services.

- Free to contact our team if you have any questions about sintered ss filters.

Stainless Steel Filters Features

- Compared with sintered bronze filter, sintered stainless steel filter has higher temperature resistance, up to 800°C.

- It has excellent corrosion resistance, acid resistance and alkali resistance

- Stainless steel filters offer high strength, good stability, and easy cleaning.

- Stainless steel filter has high filtration accuracy, minimum 0.2μm.

- Uniform pore size can be achieved.

Standard Stainless Steel Filters

- As a professional sintered SS filter manufacturer with more than ten years of experience, BLUE designs and manufactures high-performance sintered stainless steel filters for multiple industries.

- Our stainless steel filters (including 304, 316, 304L, 316L) cover different sizes, shapes, layers and porosity.

- These stainless steel filters are all standard parts, so you could place an order quickly.

- Download our product lists by simply clicking the link below.

Applications of Sintered Stainless Steel Filter

BLUE Customized Sintered Stainless Steel Filter Specifications

Below are our common custom sintered stainless steel filter specifications. Free to contact us if you have specifc needs.

| Attribute | Value |

|---|---|

| Material | 304, 316L, 304L, 316L |

| Porosity | 28%-50% |

| Filter Rating | 0.5 to 200 μm |

| Operating Temperature | -200°C to 800°C |

| Working Pressure | Maximum 5 Mpa |

| Shape | Disc, Cartridge, Cone, Tube, Sheet |

| Sintered Stainless Steel Filter Disc Size | Maximum Diameter 2000 mm |

| Sintered Stainless Steel Filter Sheet Size | Maximum Size:1500 mm Long, 1200 mm Wide |

| Sintered Stainless Steel Muffler Size | Standard Thread Size from 1/8″ to 1″ |

| Sintered Stainless Steel Tube Size | Inner Diameter 4 to 200 mm |

Download Product List

Sintered Muffler

BLUE's sintered silencer has uniform pores, significant noise reduction effect, long service life, and can be customized in various sizes.

Sintered Ceramic Filter

Sintered ceramic filter is a high-performance filter with high temperature resistance, corrosion resistance, and good surface finish.

FAQ's

Here are some of the questions we get asked often. If yours isn’t answered, don’t hesitate to contact us, we’re happy to help!

Sintered porous stainless steel filter is made of stainless steel metal powder through sintering. It has the characteristics of high temperature resistance, acid and alkali corrosion resistance, easy cleaning and high filtration efficiency.

The interior of the sintered stainless steel filter has a porous structure that can block larger particles, suspended matter and other impurities on its surface, allowing liquids and gases to pass through.

Here are some common methods for cleaning sintered stainless steel filters:

Ultrasonic cleaning: Place the sintered stainless steel filter in an inert gas furnace, heating it to 380°C for two hours. Then, immerse it in an ultrasonic cleaning device for about 30 minutes.

Chemical flushing: Chemical cleaners dissolve and remove contaminants from the sintered stainless steel filter elements.

Pyrolytic burning: Due to the high melting point of stainless steel, exposing the filters to high temperatures burns off contaminants.