Sintered Filter Disc | BLUE

BLUE sintered filter discs offer a wide filtration accuracy range from 0.2 μm to 200 microns, with material options including plastic, bronze, stainless steel, and titanium. We provide standard sintered disc filters and can also customize them according to your requirements for filtration rating, material, and size.

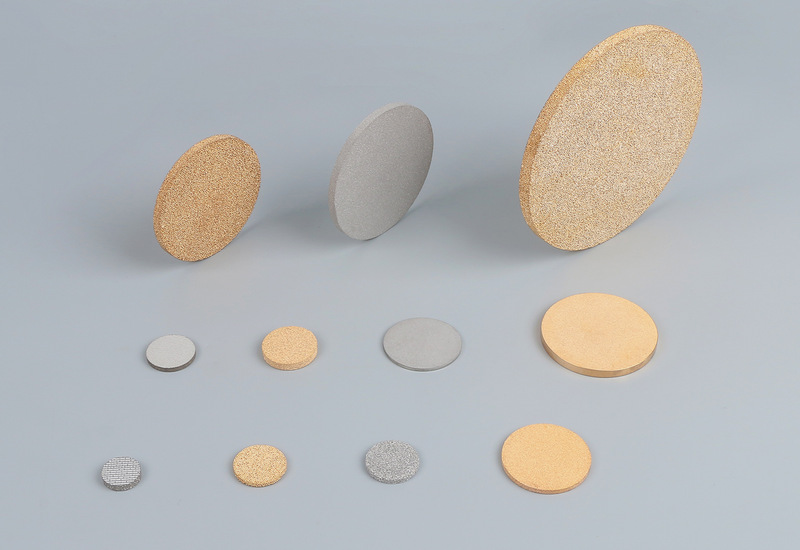

All Kinds of Sintered Filter Disc

BLUE offers consistently high-quality products, from bronze, stainless steel, and plastic materials to sintered filter discs in round, oval, annular, or woven forms.

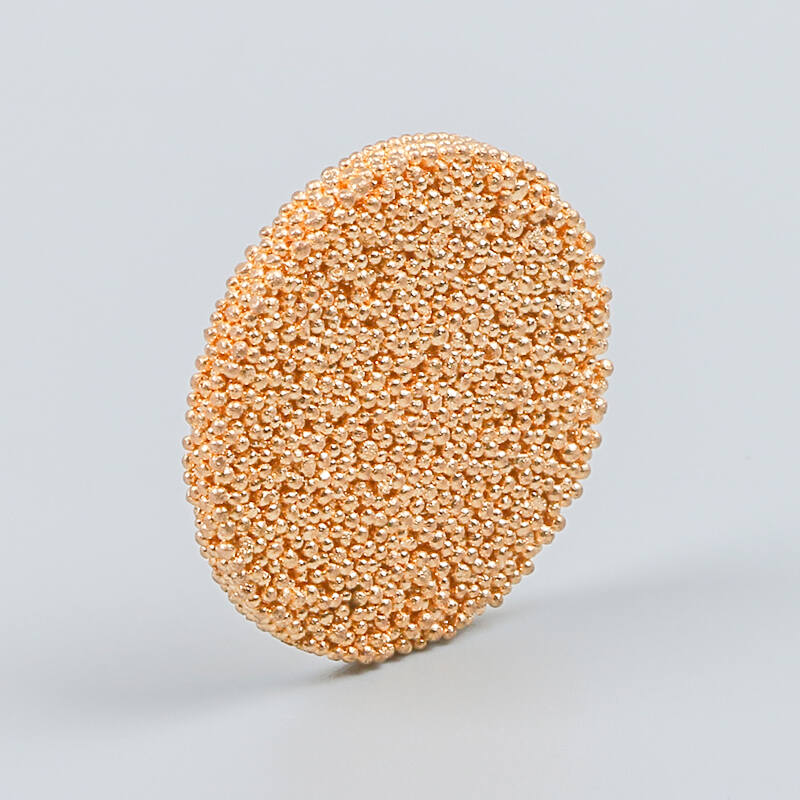

Sintered Bronze Filter Disc

BLUE's sintered bronze filter discs have a wide range of pore sizes from 1um to 130um, good corrosion resistance and durability.

Porous Stainless Steel Disc

The porous stainless steel filter uses high-quality stainless steel powder as raw material, which has good mechanical properties.

Sintered Metal Disc

BLUE sintered metal discs provide a cost-effective and efficient filtration solution fornumerous applications.

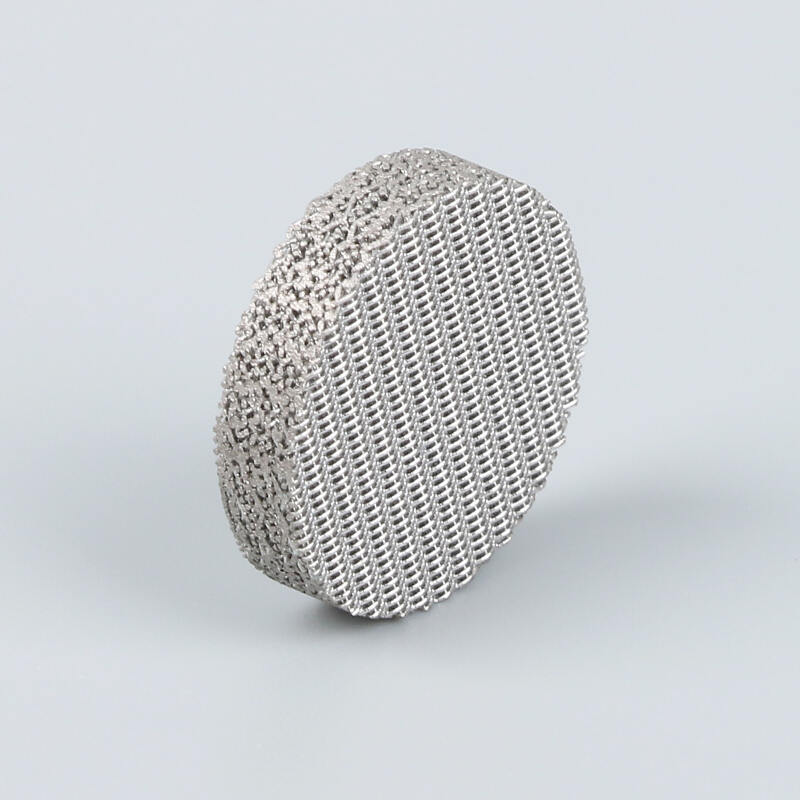

Wire Mesh Filter Disc

Our wire mesh filter discs iare made from multiple layers of woven metal, with various weaving patterns available, including plain weave, twill weave, and Dutch weave.

Stainless Steel Filter Disc

BLUE stainless steel filter discs can be customized in filtration accuracy, porosity, diameter and thickness to meet your special needs for high quality.

Sintered Metal Filter Disc

Sintered metal filter discs can still work normally under high temperature and high pressure environment, and can be cleaned and reused, with a long service life.

Sintered Plastic Filter

BLUE sintered plastic filter sheets are cheap, have high filtration accuracy, and are available in PE, PP, PTFE, and PA materials.

Powder Metallurgy Filter Disc

BLUE powder metallurgy filter disc has uniform pore size and high filtration accuracy, and can effectively filter various pollutants.

Sintered Disc Filter

BLUE sintered disc filter has precise filtering accuracy, controllable pore size, and large dirt holding capacity to meet your high quality needs.

Why Choose BLUE?

BLUE is your trusted manufacturer of top-quality sintered filter discs, backed by advanced production equipment, strict quality control, free samples, and fast delivery.

BLUE High Quality Standards

BLUE assures your product quality with ISO 9001:2015 certified quality management system. We provide a one-year warranty on our porous metal discs.

Standard Sintered Filter Disc Shop

We have a wide range of standard sintered filter discs in stock for quick delivery. Go to our shop and pick out what you need.

Download Sintered Disc List

Discover BLUE’s full range of powder metallurgy standard sintered filter discs. Download our free product list to find the exact match for your requirements.

BLUE's Sintered Filter Disc Advantages

BLUE provides you with a one-stop sintered filter disc solution with higher quality, precise filtration rating and tight tolerance than other manufacturers.

We have the full process capability to manufacture sintered filter discs, with advanced vacuum sintering furnaces, welding equipment, precision machining equipment, etc.

All sintered disc filters can be tested for filtration accuracy if necessary, ensuring that our products are 100% compatible with your specific application.

BLUE sintered filter discs perform reliably even in high pressure, corrosive environments, and can be cleaned repeatedly for long term use.

Wide Choice of Sintered Disc

BLUE is capable of producing a variety of sintered filter discs.

Materials: We can manufacture sintered filters not only from bronze, 304 stainless steel, and 316 stainless steel, but also from materials like nickel and plastic.

Shapes: We offer filters in round, oval, ring,even irregular shapes.

Weaving Process: For wire mesh filters, we provide plain weave, twill weave, and Dutch weave options.

Filtration Precision: Whether it’s filtering medium to small particles or achieving ultra-fine filtration below 1μm, BLUE sintered filter discs are up to the task.

Standard Sintered Filter Disc

As a professional sintered filter supplier, BLUE has a large number of standard sintered filter disc, including sintered bronze filter disc, sintered stainless steel disc, wire mesh filter disc.

Our sintered filters are highly praised by our customers for their high quality, competitive price, long service life and high filtration efficiency.

All these sintered metal filter disc in stock for fast delivery. You can click the botton below to download our product list to pick out what you need.

If you have customized requirements, our team is here to help you.

Applications of Sintered Metal Filter Disc

Sintered filter disc has a porous structure inside, which can diffuse sound, so it is used in acoustic equipment.

Oil and Gas Industry

BLUE metal filter discs offer excellent high-temperature and corrosion resistance, making them the ideal filtration solution for corrosive liquids and gases in oil and gas applications.

Pharmaceutical Industry

Sintered filter discs provide high filtration precision, not only for removing contaminants from medicines but also for controlling particle size, ensuring consistent quality.

BLUE Customized Sintered Filter Disc Specifications

Below are BLUE’s custom specifications for manufacturing sintered filter discs.

| Sintered Filter Disc Type | Filtration Rating | Porosity | Size |

|---|---|---|---|

| Sintered Bronze Filter Disc | 1 – 100 Microns | 35% – 45% | Diameter: 5 – 300mm Thickness: 1 – 70mm |

| Sintered Stainless Steel Filter Disc | 0.2 – 200 Microns | 28% – 50% | Diameter: 5 – 450mm Thickness: 1 – 100mm |

| Wire Mesh Filter Disc | 1 – 200 Microns | 30% – 50% | Diameter: 5 – 1000mm Thickness: 1 – 15mm |

Download Product List

FAQ's

Here are some of the questions we get asked often. If yours isn’t answered, don’t hesitate to contact us, we’re happy to help!

There are two common sintered filter discs:

- Porous metal disc is made from metal powders, such as bronze or stainless steel, fused together through high-temperature sintering to achieve the desired mechanical properties.

- Wire mesh filter disc is crafted from single or multi-layer woven metal that is pressed and sintered. Typically, our sintered wire mesh consists of 1 to 7 layers and can feature plain, twill, or Dutch weaves.

Here are some sintered filter disc cleaning methods:

Ultrasonic cleaning

First, place the sintered filter dissc in a heating furnace for two hours, and then place the product in an ultrasonic cleaner for about half an hour.

Chemical flushing

You can also use chemical solvents to clean the dirt on the sintered filter disc.

Pyrolysis burning

Sintered stainless steel discs have a higher melting point, so you can expose them to high temperatures to burn off contaminants.