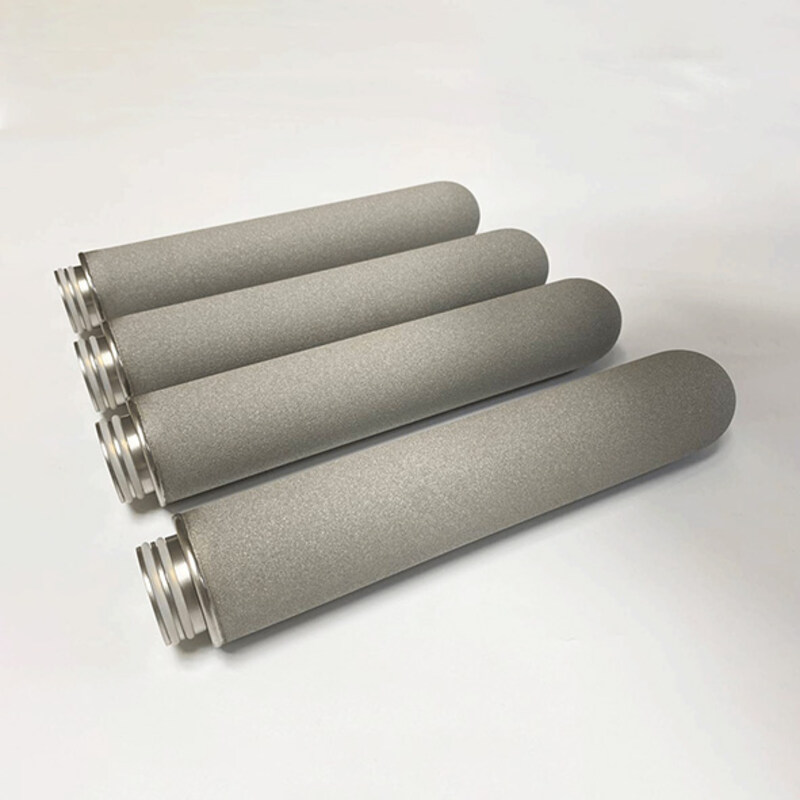

BLUE Sintered Filter Cartridge

BLUE supplies a wide range of high quality sintered filter cartridges, covering stainless steel, titanium, nickel, high temperature resistance up to 930°C, and compressive strength up to 4Mpa. Our sintered metal filter cartridges can be customized with filter accuracy, diameter, connection types, etc.

All Kinds of Sintered Filter Cartridge

BLUE offers sintered powder metal filter cartridges and sintered mesh filter cartridges in various filtration ratings and diameter sizes. Our sintered filter cartridges have controllable pore sizes and can effectively remove fine suspended matter and particles.

Sintered Cartridge Filter

Sintered cartridge filter uses metal powder as raw material and is formed by isostatic pressing and high temperature sintering.

Sintered Metal Filter Cartridge

BLUE sintered metal cartridge filter is easy to clean, low maintenance cost and long service life.

Sintered Powder Filter Cartridge

Sintered powder filter cartridge is made of metal powder, with controllable porosity and good filtering effect.

Sintered Powder Metal Filter Cartridge

Sintered powder metal filter cartridge offers 99.9% filtration efficiency, adjustable permeability, and a maximum compression burst strength of 4 MPa.

High Flow Sintered Filter Cartridge

BLUE high-flow sintered filter cartridges offer uniform pores, high permeability, and strong contaminant capacity, widely used in chemical and petrochemical industries.

Sintered SS Filter Cartridge

BLUE Sintered SS filter cartridge has good mechanical properties, excellent corrosion resistance, and high temperature resistance up to 810℃

Sintered Mesh Filter Cartridge

BLUE sintered mesh filter cartridge is made by rolling multiple layers (usually 5 layers) of metal into a cylindrical shape and then welded the connection port.

Stainless Steel Sintered Filter Cartridge

Stainless steel sintered filter cartridge has a wide temperature range from -200℃ to 600℃ and can be cleaned to extend service life.

Sintered Cartridge

BLUE sintered cartridges can be made of stainless steel, titanium, or nickel, allowing for customization of inner and outer diameters, lengths, and filtration accuracy.

Why Choose BLUE?

BLUE provides top quality sintered filter cartridges, supported by advanced isostatic pressing equipment and vacuum sintering furnaces, along with a strict quality management system—assuring excellent quality across our entire product range.

BLUE High Quality Standards

BLUE assures your product quality with ISO 9001:2015 certified quality management system. We provide a one-year warranty on our sintered filter cartridge.

Standard Sintered Filter

Cartridge Shop

We have a wide range of standard sintered filter cartridges in stock for quick delivery. Go to our shop and pick out what you need.

Download Sintered Filter Cartridge Product List

Discover BLUE’s full range of powder metallurgy standard sintered filter cartridge. Download our free product list to find the exact match for your requirements.

BLUE's Sintered Filter Cartridge Advantages

As a professional sintered filter cartridge, BLUE has a strict quality management system to strictly control the production process.

We have a series of advanced isostatic pressing equipment, vacuum sintering furnaces and and precision machining equipment to guarantee product quality.

BLUE sintered nickel filter cartridge has excellent corrosion resistance and a maximum temperature resistance of more than 900℃, suitable for extreme environments.

Our sintered filter cartridge has high compressive strength, and you can clean and use it repeatedly, reducing maintenance costs

Sintered Filter Cartridge Benefits

Sintered cartridges are made of porous metal, woven wire mesh or fiber felt, vacuum sintered, with uniform pores, strong dirt holding capacity and high filtration efficiency.

It is made of stainless steel or titanium alloy, with a wide operating temperature range and excellent corrosion resistance.

Sintered metal cartridges are easy to clean and can be used repeatedly, with a long service life.

Its compressive strength can reach more than 4 Mpa.

Standard Sintered Filter Cartridge

BLUE offers numerous standard sintered cartridges for various applications, including the chemical, petrochemical, and machinery industries.

Our sintered filter cartridge has a variety of connection types, including internal thread, external thread, plug-in, sanp-in, etc.

All standard sintered cartridges are in stock for quick delivery.

Free download our standard product list to choose the products you need.

Sintered Filter Cartridge Applications

BLUE Sintered Filter Cartridge Specifications

Below are some of our standard sintered cartridge specifications that you can directly purchase in our standard parts shop. Free to contact our team if you have custom requirements.

| Attribute | Value |

|---|---|

| Material | SS 304, SS 316, Titanium, Nickel |

| Length | Maximum 3000 mm |

| Filtration Rating | 0.2 to 200 μm |

| Working Temperature | -200℃ to 930℃ |

| Diameter | 10-400 mm |

| Permeability Coefficient | 0.06-9.43 (10⁻⁷ m²) |

| Compressive Burst Strength | 2.5-4 Mpa |

| Thread Type | Metric, BSPP, BSPT, NPT, etc. |

Download Product List

FAQ's

Here are some of the questions we get asked often. If yours isn’t answered, don’t hesitate to contact us, we’re happy to help!

The following are common sintered filter cartridge cleaning methods:

Ultrasonic cleaning

Put the sintered filter cartridge in an inert gas-protected heating furnace and heat it for two hours. Then, put the product in an ultrasonic cleaner for about 30 minutes.

Chemical flushing

Remove dirt from the sintered filter cartridge by using chemical solvents.

Pyrolysis burning

Sintered filter cartridges have a high melting point, and you can expose them to high temperatures to burn off contaminants.