China Powder Metal Parts | BLUE

BLUE has over 20 years of experience in powder metal parts design and manufacturing, providing standard PM parts and customized services. Our strict quality control system ensures high standards at every step of the production process, guaranteeing the high quality of your products.

Why Choose Us?

BLUE is your trusted manufacturer of high-quality powder metal parts, supported by advanced production equipment, strict quality control, free samples, fast delivery, and competitive pricing from China.

BLUE High Quality Standards

BLUE assures your product quality with ISO 9001:2015 certified quality management system. We provide a one-year warranty on your products.

Standard PM Parts Shop

BLUE has a full range of standard powder metallurgy parts in stock for fast delivery. Visit our standard parts shop to find the exact match for your applications.

Free Mold Design Service

With over 20 years of expertise in mold design, BLUE offers free, high-precision mold design services to meet your customized needs. Let our experience work for you!

What is Powder Metal Part?

A powder metal part is a solid component formed by compacting metal powder and sintering it below its melting point. This process creates near-net-shape parts with precise dimensions, low material waste, and good part-to-part consistency, making it ideal for high-volume production.

Powder metal parts provide cost efficiency and allow complex geometries that are difficult to machine or cast. Secondary operations can enhance the strength and wear resistance of sintered parts.

Powder metal components are widely used in industries such as automotive, home appliances, power tools, lock mechanisms, aerospace, and medical devices due to their cost-effectiveness and excellent consistency in quality.

What is Powder Metal Manufacturing Process?

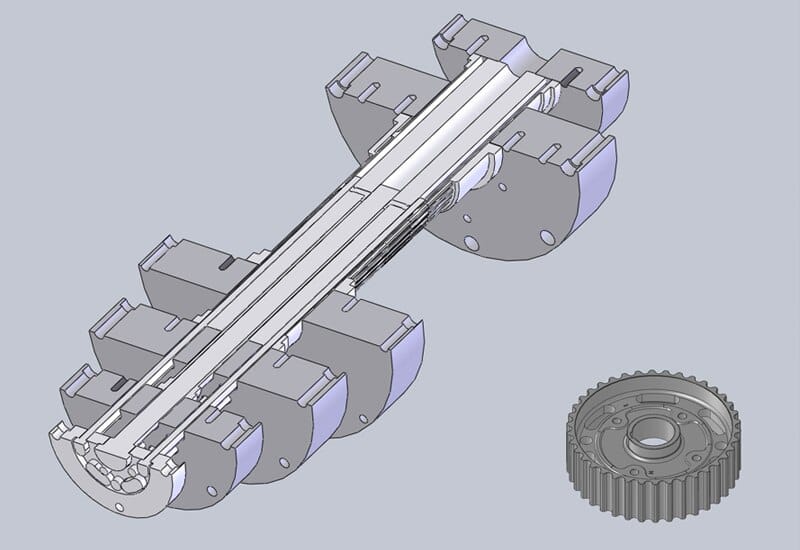

Powder metal manufacturing process, also known as powder metallurgy process, forms metal powders into solid components through compaction and sintering. Metal powders are first produced through methods such as atomization or mechanical milling, and then blended with alloying elements and binders to achieve the required flow, compressibility, and properties.

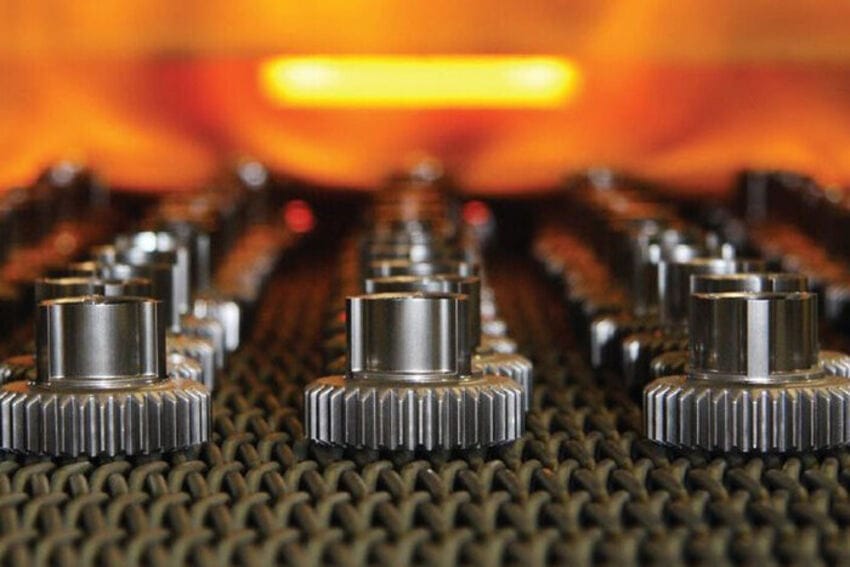

The blended powder is compacted in a precision die at room temperature to create a near-net-shape green part. Generally, the common pressure for powder metal part molding is 400-800MPa, This green compact is then sintered in a controlled atmosphere at a temperature below the metal’s melting point, which bonds the particles together and develops the part’s strength, density, and microstructure. The typical sintering temperatures are approximately 1120 °C for iron-based components, 1250 °C for stainless steel, and 820 °C for copper materials.

After sintering, parts may receive secondary treatments such as sizing, machining, heat treatment, infiltration, or forging to improve dimensional accuracy, mechanical properties, or surface quality.

BLUE Quality Management System

Powder metallurgy parts from BLUE are strictly controlled by ISO 9001:2015 and IATF 16949:2016 to ensure that high-quality products are delivered to you as quickly as possible.

We strictly controls the parameters of powder compaction presses and sintering furnaces to ensure consistent quality of different batches.

BLUE provides blister trays to protect powder metallurgy parts during transport. These parts are packed in sturdy cartons with multiple layers and placed in fumigation-free wooden boxes to guarantee they arrive in perfect condition.

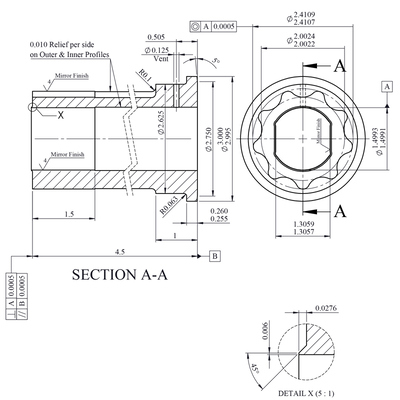

Tight Tolerance Control

Powder metallurgy parts are known for their high precision, especially after sizing, with product size tolerance between IT5 and IT7.

For instance, a sintered part with a diameter of 25mm after sizing will have a tolerance of 0.05% to 0.08%, equating to 12.5μm to 20μm.

As a premier sintered parts manufacturer, BLUE features an advanced inspection center that conducts full inspections to ensure each part meets the specified tolerance requirements

Improved Mechanical Properties

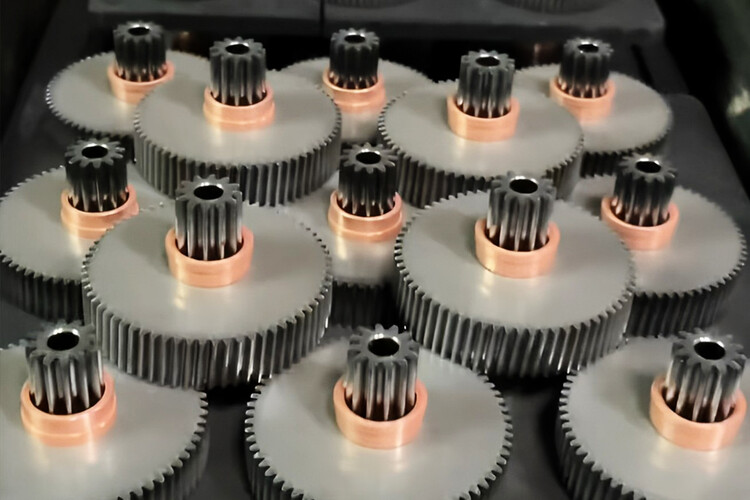

Powder metallurgy components contain internal pores, which can be challenging for use in strict environments.

To address this, we offer copper infiltration and resin filling options.

Copper infiltration not only fills internal pores but also enhances the product’s strength and density; however, it is relatively costly.

Resin impregnation is a more economical method, though it has the drawback of being susceptible to dissolution in high-temperature environments.

It also aids in the electroplating process by preventing the plating solution from corroding the product’s interior.

Customized Powder Metallurgy Parts

If you can’t find the same powder metallurgy parts in our standard PM parts shop, we offer custom solutions.

With years of experience in PM mold design, BLUE can manufacture a wide range of powder metallurgy parts to meet your unique requirements.

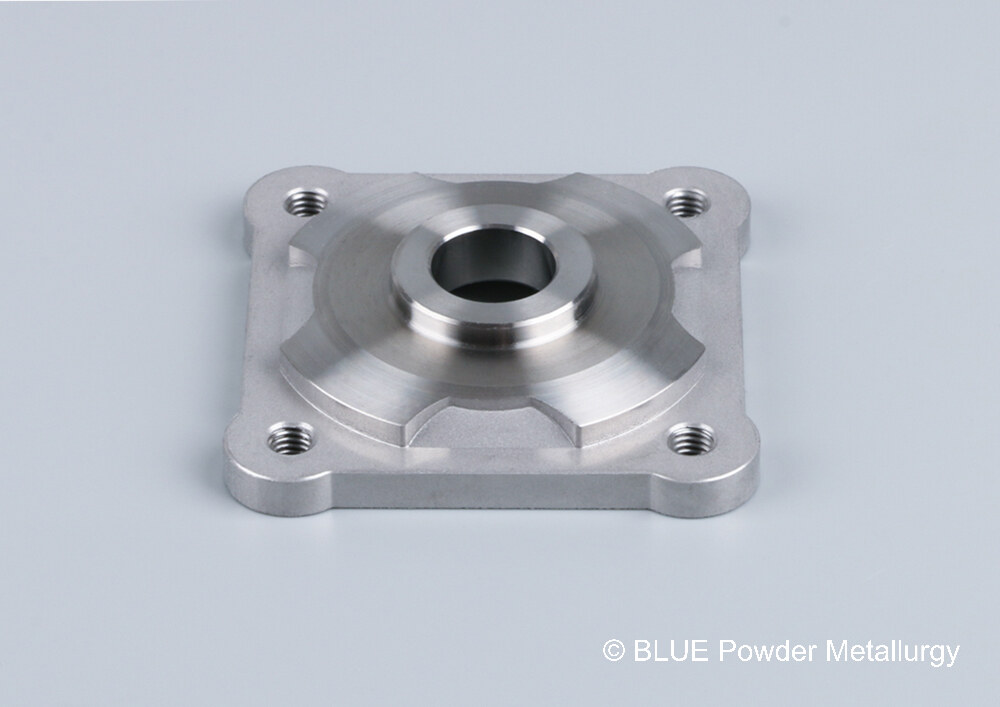

Our customized products include but are not limited to pulleys, gears, oil impregnated bearings, ABS detection rings, shock absorber parts, impellers, flanges, sprockets, etc.

For questions about mold design, contact our engineers anytime—we offer free mold design services

Custom Powder Metallurgy Parts Capabilities

The following are BLUE’s custom powder metallurgy parts capabilities, including part size, weight, wall thickness, surface roughness, etc.

| Attribute | Value |

|---|---|

| Size | Diameter 5 to 250 mm |

| Length | 5 to 200 mm. |

| Wall thickness | Minimum wall thickness is 1.5mm |

| Surface finish | Ra 0.8μm to Ra 1.6μm |

| Weight | 3 to 2000 grams |

| Tolerance | ±0.01 mm |

| Sintered Hardness | 50-70 HRB |

| Hardened Hardness | 30 HRC min |

| Material | All materials comply with MPIF 35 or DIN 30910 or JIN Z 2550 standards |

FAQ's

Here are some of the questions we get asked often. If yours isn’t answered, don’t hesitate to contact us, we’re happy to help!

Powder metallurgy has a wide range of material options, including:

- Ferrous materials

- Bronze

- Brass

- Aluminum alloys

- Stainless steels

- Titanium alloys

- Nickel-based super alloys

You can choose mixed powders and pre-alloyed powders to make powder metal parts.

Compacted metal powders only have a strength similar to chalk, making them prone to breaking and unable to meet usage requirements. Sintering is heating the green compact below the metal’s melting point, enhancing its strength, hardness, and other mechanical properties.

Powder metallurgy products contain internal pores, so they cannot achieve complete density like casting and forging. For example, iron-based powder metallurgy parts can reach 7.2 g/cm³ with one-time compacting and sintering. Using secondary compacting and secondary sintering or a copper infiltration process can achieve densities of 7.2 to 7.6 g/cm³. Powder forging can produce sintered metal parts exceeding 7.6 g/cm³, but the cost is greatly increased.