Sintered Oil Pump Impeller Supplier

BLUE offers more than 100 standard oil pump impellers with no tooling fees. Our impellers are available in a wide range of models to fit most oil pumps, with micron-level tolerances, good corrosion resistance and long-lasting durability.

Why Choose BLUE?

BLUE offers high-quality oil pump impellers with free samples, fast shipping, and competitive prices – your trusted partner.

BLUE High Quality Standards

BLUE assurethe quality of your SINTERED impellers with an ISO 9001:2015 certified quality management system. Free samples are available for testing.

Standard Oil Pump Impeller Shop

BLUE has a full range of standard oil pump impelles in stock for fast delivery. Visit our standard parts shop to find the exact match for your applications.

OEM & ODM Services

With over 20 years of expertise in designing and manufacturing powder metallurgy parts, BLUE provides OEM and ODM services for you.

BLUE Oil Pump Impeller in China

BLUE offers a range of high-quality sintered impellers to ensure optimal performance from your oil pump.

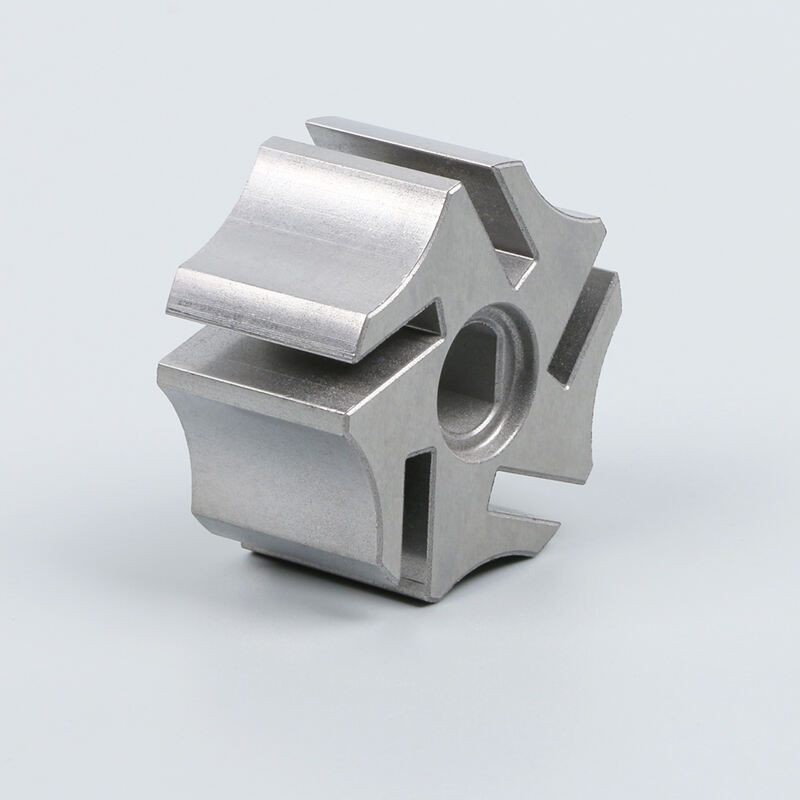

Powder Metallurgy Oil Pump Impeller

BLUE's powder metallurgy impeller is made by compacting metal powder under high pressure with little material waste.

Sintered Metal Oil Pump Impeller

Our high quality sintered metal oil pump impeller can achieve tight tolerances, even ±0.01mm.

Powder Metal Impeller

Our powder metal oil pump impeller has good mechanical strength, toughness and long using life.

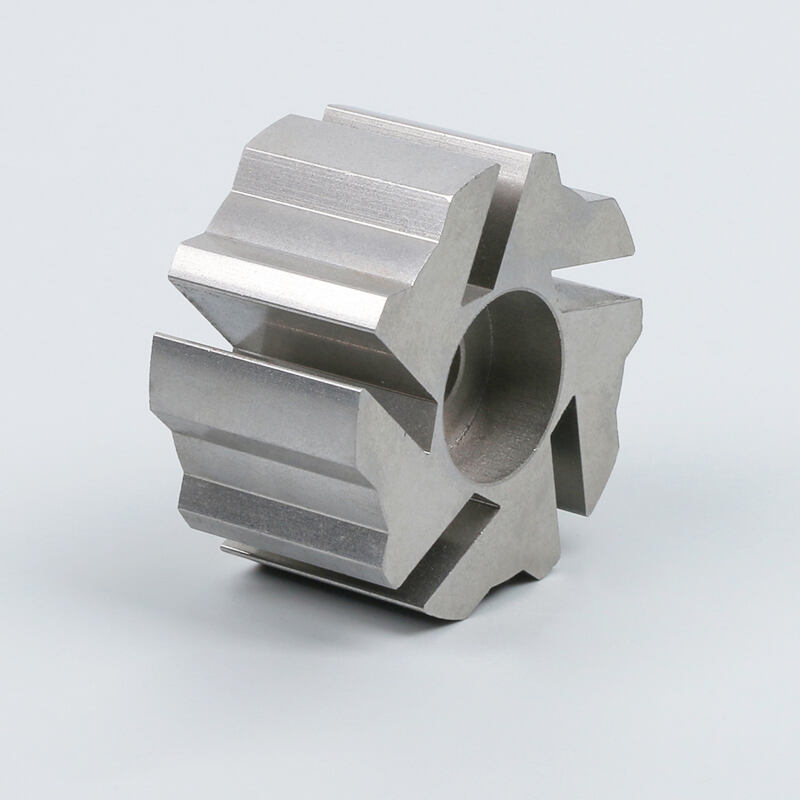

Sintered Oil Pump Impeller

Our sintered oil pump impellers have uniform density and reliable quality, which helps to achieve the best performance of the oil pump.

Powder Sintering Impeller

BLUE powder sintered impeller uses FC-0205 as raw material and has good corrosion resistance after surface treatment.

Powdered Metallurgy Impeller

BLUE standard powder metallurgy impeller outer diameter ranges from 30 to 50mm, inner hole diameter ranges from 5 to 15mm.

What is an Oil Pump Impeller?

Oil pump impeller is the rotating component inside the engine oil pump. It draws oil from the oil pan and delivers it to the lubrication system. Oil pump impeller uses centrifugal or rotational force to drive the oil movement, enabling the pump to build pressure and deliver a steady flow of oil to engine bearings, pistons, and other moving parts.

Impellers typically have curved or angled blades. As they rotate, these blades accelerate the outward flow of oil, creating suction at the center and pressure at the outlet. This design achieves a smooth, continuous oil flow and is widely used in centrifugal or vane-type oil pumps.

Standard Oil Pump Impeller

As China’s largest powder metallurgy standard parts supplier, we have a range of standard parts.

These standard parts, including oil pump impellers, do not require tooling fees.

You can check the table below to get the specifications of these standard oil pump impellers.

Download our powder metallurgy standard parts product list for free.

BLUE Oil Pump Impeller Features

BLUE’s powder metallurgy parts are produced under the strict control of the IATF 16949:2016 system.

Our sintered impellers feature an inner hole tolerance of ±0.015mm, ensuring precise fitment on the shaft.

BLUE have an experienced team of designers who can design your oil pump impeller according to specific requests.

We can also provide oil pump impeller blades according to your needs.

Standard Oil Pump Impeller

As China’s largest powder metallurgy standard parts supplier, we have a range of standard parts.

These standard parts, including oil pump impellers, do not require tooling fees.

You can check the table below to get the specifications of these standard oil pump impellers.

Download our powder metallurgy standard parts product list for free.

Advantages of Sintered Oil Pump Impeller

High Precision

Powder metallurgy produces impellers with tight tolerances, ensuring optimal oil flow and pump performance.

Material Efficiency

Sintering oil pump impellers through powder metallurgy minimizes material waste and allows the use of alloys tailored to specific performance requirements.

Cost-Efficient Production

Making oil pump impellers in bulk with powder metallurgy cuts costs and ensures consistent quality.

Working Principle of Oil Pump Impeller

The oil pump impeller is driven by the engine’s crankshaft or an electric motor.

As it spins, its blades generate centrifugal force, drawing oil from the tank or sump into the center.

This force then pushes the oil outward to the impeller’s outer edge, creating pressure that forces the oil through the pump housing and into the engine’s lubrication system.

Standard Oil Pump Impeller Specifications

The following table shows our standard oil pump impeller specifications, including material, density, tolerance, diameter, etc.

| Attribute | Value |

|---|---|

| Material | MPIF 35 FC-0205. FC-0208, FN-0205, FD-0208 |

| Density | 6.6-7.0g/cm3 |

| Hardness | 65-90 HRB |

| Surface Treatment | Steam Treatment, Dacromet, Electroplating |

| Outer Diameter | ⌀30 to ⌀50mm |

| Internal Hole Diameter | ⌀5 to ⌀15mm |

| Length | 10 to 30mm |

| Tolerance | ±0.01 mm |

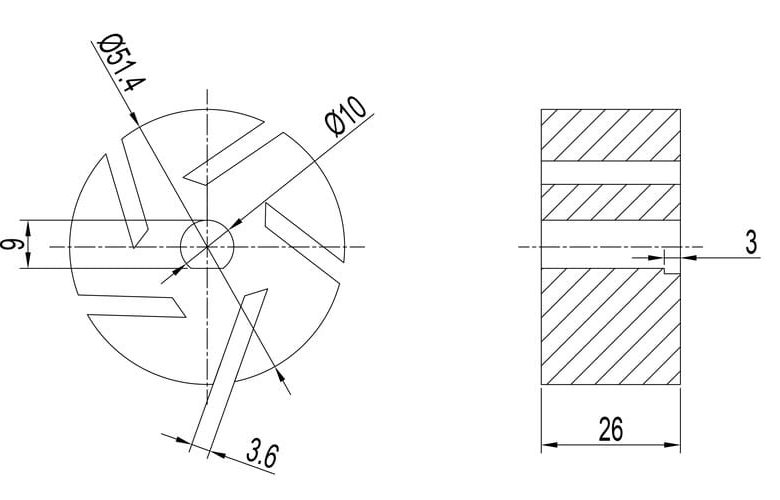

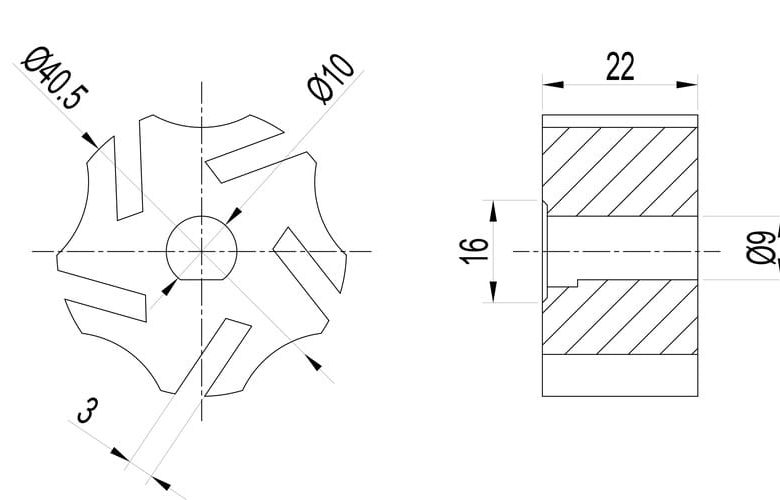

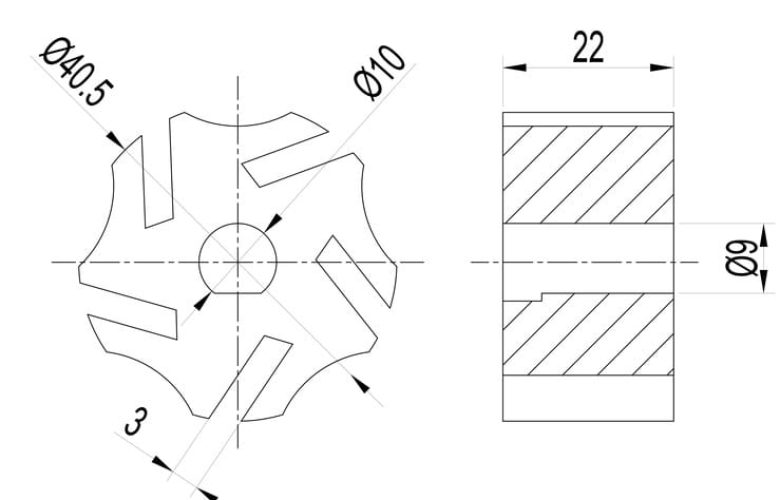

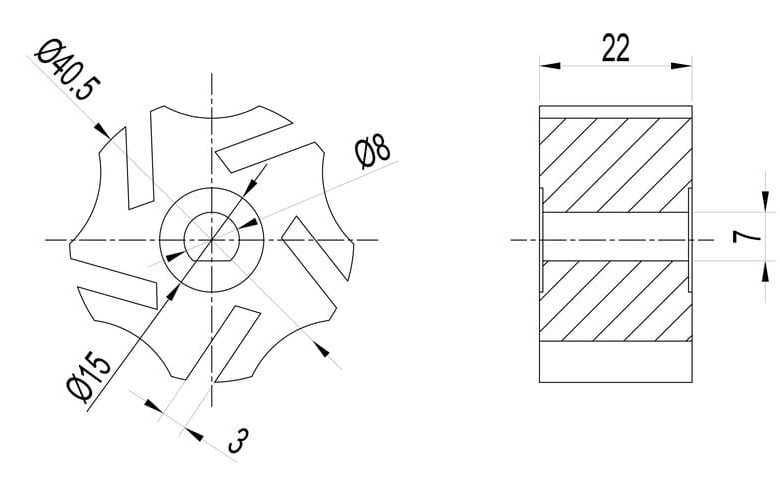

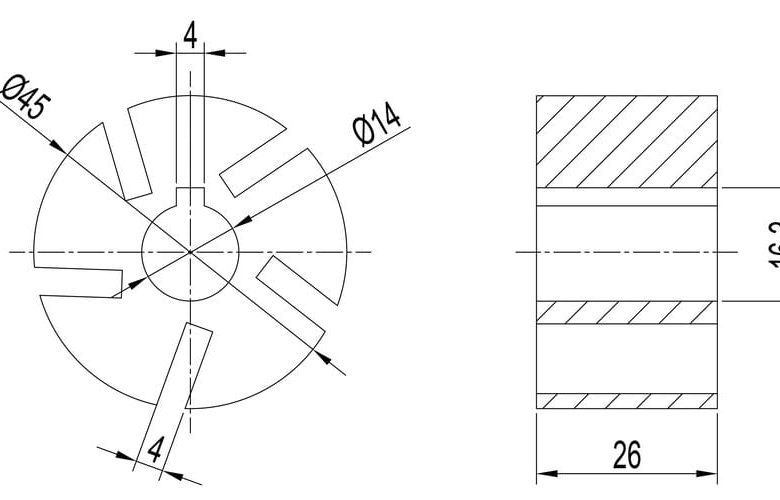

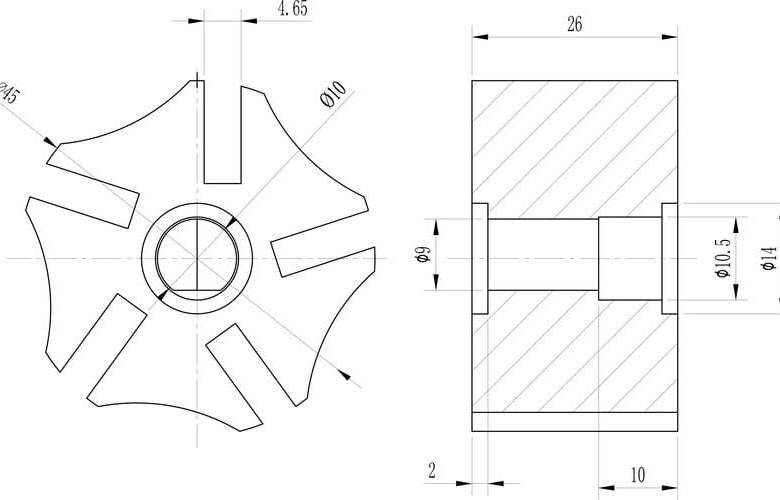

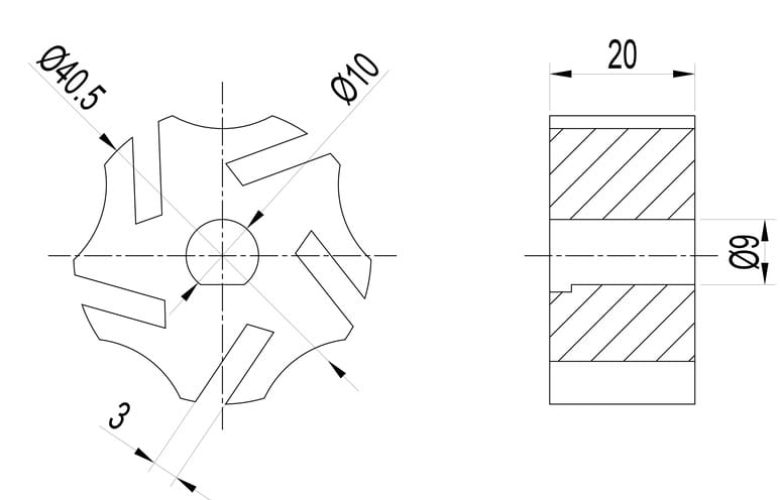

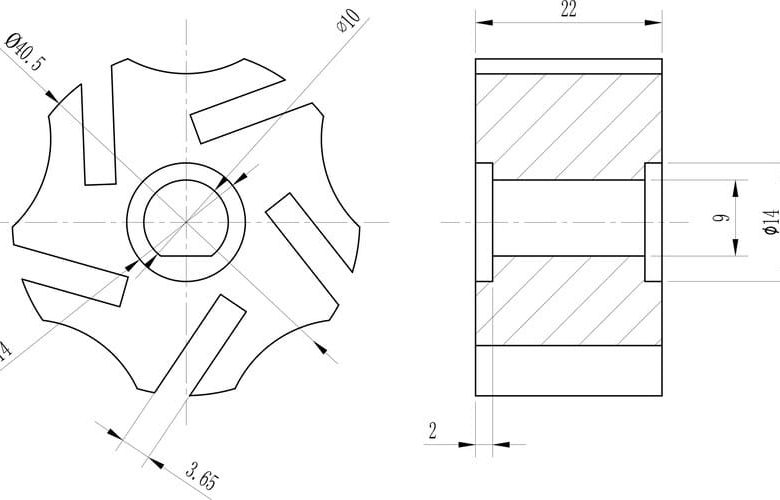

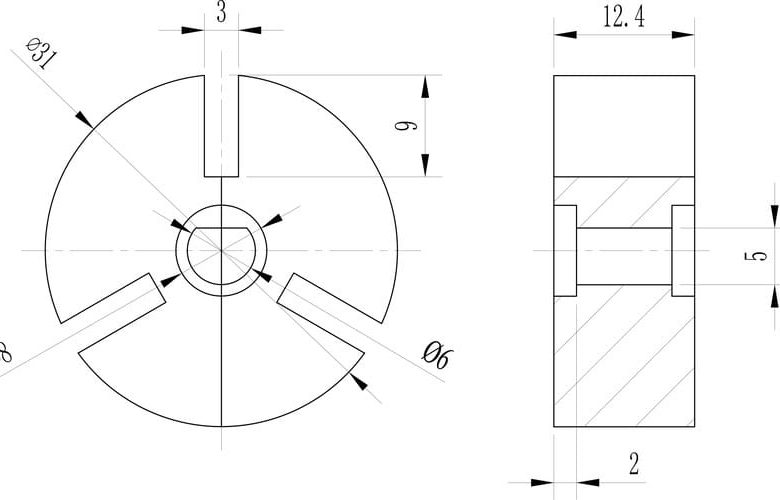

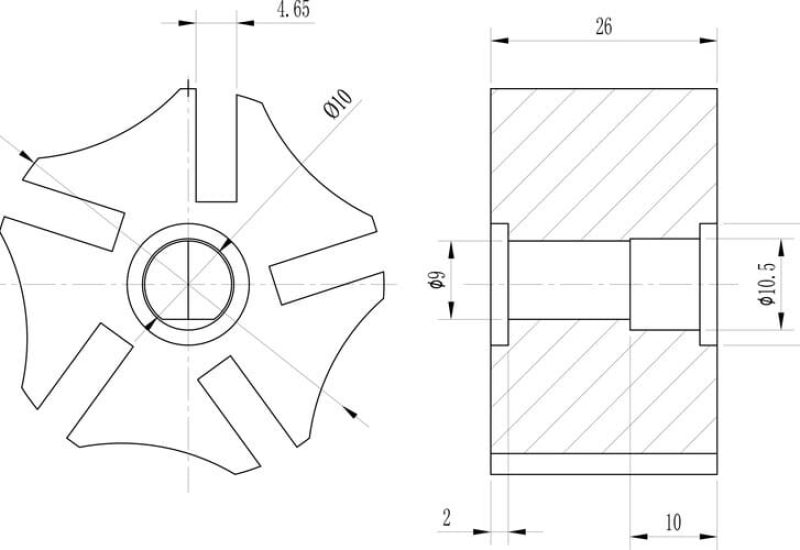

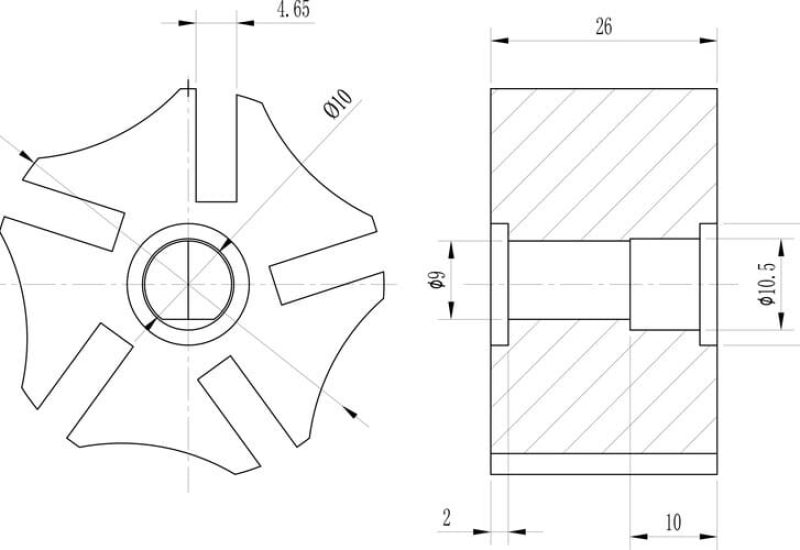

Standard Oil Pump Impeller Drawings

Below are some drawings of our common standard oil pump impellers, if you find an exact match contact us for more.