The process of converting raw materials such as ores and alloys into useful metal products is known as a metal manufacturing process. There are multiple metal manufacturing processes, such as casting, forging, powder metallurgy, and CNC machining.

These processes fall in the category of bulk metallic manufacturing processes, which can be used to get the desired metal components. Each method offers unique advantages depending on factors such as material type, desired shape, precision, and production scale. With the help of these methods, we can produce simple metal sheets to complex metal components for various industries such as aerospace, automotive, or engineering.

Contents

Casting

Metal casting process is considered one of the ancient methods for manufacturing metal components. In this technique, first of all, a mold is designed according to the desired component. Then, the molten metal is poured into this mold which solidifies on cooling. The components are taken out of the mold as it cools, and then further finishing treatments are done to get the desired properties.

Sand Casting

In this casting process, the molds made with sand are utilized in which molten metal is poured into converting it into the desired component. This type of casting is considered universal for manufacturing large engines to statues and other art pieces.

Investment Casting

Such casting is also referred to as lost wax casting. In this technique, the wax mold is created, which is then encased with ceramic. After solidifying ceramics, the wax is melted away, and a mold is formed for the desired components in which molten metal is poured. This type of casting is considered for high precision and accuracy in components, such as in the manufacturing of turbine blades in the power generation industry.

| Advantages of Casting | Limitations of Casting |

|---|---|

| Versatility in complex shapes and designs | Gas porosity due to trapped gases |

| Cost-effective for large production runs | Can show shrinkage defects from poor material feed |

| Compatible with many materials (metals, plastics, ceramics) | Mold material defects from erosion or pressure |

| High strength and mechanical reliability | Pouring defects like cold shuts and misruns |

| Precision and minimal waste with reusable material | Metallurgical defects such as hot tears |

Forging

Forging is a process in which a metal is strengthened and shaped into desired components by applying compression either by hydraulic press or mechanical presses. It is widely used in various industries such as aerospace, oil and gas industries, producing components including high-pressure valves, crankshafts, ball joints, gears and cams.

On the basis of the temperature at which the metal is forged, it has been divided into two types:

Hot Forging

Here, the metal or its alloys are heated 0.3 to 0.4 times its melting temperature, and then forces are applied to get the desired component. For example 7000 alloys of aluminium are forged at 400–440 °C whereas 2000 aluminium alloys are forged at 425–460 °C. This type of forging requires less force, and metals can be compressed easily when hot. However, it may not give the desired finishing; hence needs an additional finishing process. It is widely used for manufacturing components in the aerospace industry.

Cold Forging

The forging of metal at room temperature is termed cold forging since metal is not heated at elevated temperatures. It requires more force to get the desired shape. Cold forging offers high dimensional accuracy but the components can lead to cracking due to low elasticity.

| Advantages of Forging | Limitations of Forging |

|---|---|

| Produces parts with superior mechanical properties and high strength | It may require expensive heat treatment for optimal properties |

| Eliminates internal voids and porosity, enhancing reliability | Complex geometries are difficult to achieve |

| Minimal waste due to near-net shape forming | Initial tooling and die costs can be high |

Powder Metallurgy(PM)

The powder metallurgy process is recognized as a green manufacturing method that uses metal powders as raw materials, forms parts by die compacting, and then sinters them to obtain the final components. In this process, metal powder is first compacted into the near-net shape of the desired component and then sintered. The components obtained through PM possess outstanding mechanical properties. This technique is used to manufacture components for multiple industries that require high precision and great mechanical strength, such as automotive and engineering.

Press and Sinter

This is the most common and conventional powder metallurgy technique. Here, metal powders are compacted in a die under high pressure and then sintered in a controlled atmosphere furnace. It is widely used for producing gears, bearings, and structural parts with uniform dimensions.

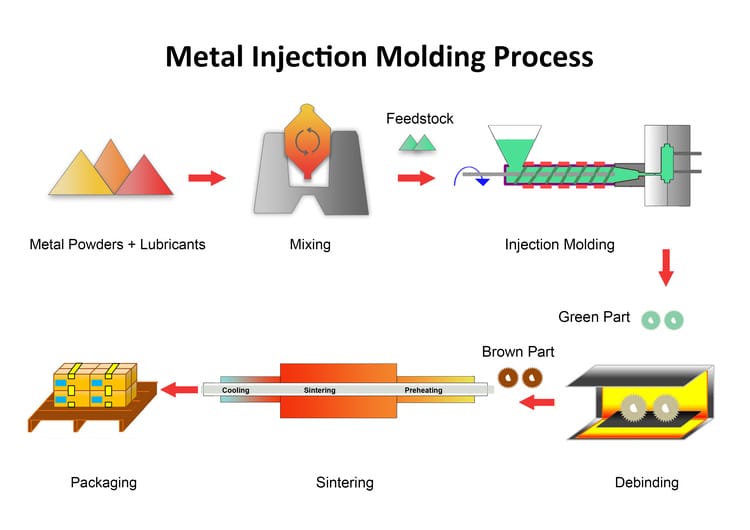

Metal Injection Moulding (MIM)

In metal injection molding process, fine metal powders are mixed with a binder material to form a feedstock; this feedstock is then injected into a mold, and after shaping, the binder is removed, and finally, the part is sintered. This method is ideal for producing small, complex, and high-precision components such as those used in medical devices and electronics.

Advantages and Limitations of Powder Metallurgy

Advantages of PM

Powder metallurgy provides high material efficiency with minimal waste as well as it can produce intricate and precise shapes without the need for machining. It is Ideal for high-volume production with consistent quality.

Limitations of PM

- Raw metal powders can be expensive

- Limited to relatively small and moderate-strength components

- High initial tooling and die costs

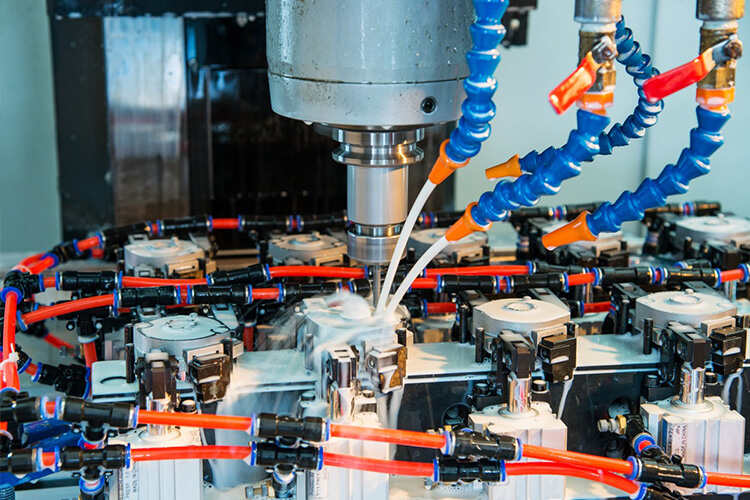

CNC Machining

CNC (Computer Numerical Control) Machining is a highly precise and automated manufacturing process. In this process, pre-programmed computer software controls the movement of tools and machinery for cutting, drilling, or milling. It is widely used in producing complex parts with tight tolerances from metals. This process is used extensively in the aerospace, automotive, electronics, medical, and defense industries.

Here are some types of CNC machining:

CNC Milling

CNC milling typically uses rotating multi-point cutting tools to remove material from a stationary workpiece. It is ideal for creating slots, holes, pockets, and 3D contours.

CNC Turning

In this process, the workpiece is rotated at high speed while a stationary cutting tool moves linearly to remove material. It is considered best for shafts, bushings, threaded parts, and components with rotational symmetry.

CNC Drilling

CNC drilling uses rotating drill bits to create precise holes in a workpiece. It is used for high-speed, high-accuracy hole production in metals and plastics.

CNC Grinding

To achieve fine surface finishes CNC grinding involves a rotating abrasive wheel. It is commonly used for finishing hardened metal parts as well as to achieve tight dimensional tolerances.

CNC EDM (Electrical Discharge Machining)

This process uses electrical sparks to erode material from conductive workpieces. One of the most remarkable features of this process is that there is no physical contact between the tool and the workpiece. It is further divided into two types, including Wire EDM and Sinker EDM. This process is considered excellent for hard metals and complex internal geometries, such as molds and turbine blades.

| Advantages of CNC Machining | Disadvantages of CNC Machining |

|---|---|

| Offers high dimensional accuracy and repeatability | Requires skilled operators and programmers for optimal performance |

| Automated operation reduces human error and allows 24/7 production | The high initial investment in machinery and setup costs |

| Works with a wide range of materials and is suitable for various applications | Not cost-effective for very low-volume or simple parts |

| Minimal need for finishing or post-processing in many cases | Tool wear and maintenance can add to long-term operating costs |

Metal Stamping

Stamping places a metal sheet between two dies and applies force to shape the material into the desired form. It includes various operations such as:

-

Blanking – cutting out a flat shape from the sheet.

-

Bending – forming angles or curves.

-

Punching – creating holes or cutouts.

-

Drawing – forming a flat sheet into a 3D shape.

Stamping is commonly utilized in high-volume manufacturing for automotive components, appliances, and electronics due to its high speed, precision, and cost-effectiveness.

Additive Manufacturing (3D Printing)

In metal additive manufacturing processes, the components are built layer by layer with the help of digital 3D models. The process begins with creating a digital design using CAD software, which is then converted into a format readable by the 3D printer. The printer deposits material layer by layer and fuses it according to the model into the desired component. It is considered ideal for manufacturing lightweight, complex parts such as brackets, ducts, and housings.

Direct Metal Laser Sintering

In direct metal laser sintering, a high-powered laser beam is used to fuse the metal particles layer by layer to obtain the desired components. It is used to manufacture highly detailed, complex geometries with excellent mechanical properties.

Electron Beam Melting

In electron beam melting, instead of a laser, a high-speed beam of electrons is used to sinter the metal powder particles. Since this process operates at high temperatures, it is particularly suitable for high-performance materials like titanium and cobalt-chrome alloys.

Selective Laser Sintering (SLS)

In this method, a laser sinters powdered material is used to form solid parts. SLS does not require support structures; therefore it is considered ideal for functional prototypes and low-volume production.

| Advantages of Additive Manufacturing | Limitations of Additive Manufacturing |

|---|---|

| Can produce highly complex and customized geometries without extra cost | Limited by build volume and part orientation |

| Speeds up product development with fast iteration cycles | Not ideal for large-scale or mass-production |

| Minimal waste since material is added only where needed | Material choices are more limited compared to traditional methods |

Extrusion

Extrusion is a metal manufacturing process for producing long, continuous shapes with a uniform cross-section. In this technique, a metal is forced through a die of the desired shape under high pressure. The extruded material takes the shape of the die opening and is then cut to the required length. It is known for its high production rate and ability to form complex profiles efficiently.

The metal extrusion manufacturing process is divided into the following types:

Hot Extrusion

In this process, the material is heated above its recrystallization temperature before being forced through the die. It is commonly used for aluminum, copper, and magnesium alloys.

Cold Extrusion

The process is performed at or near room temperature. This method offers a better surface finish, higher dimensional accuracy, and improved mechanical properties. It is typically used for steel, lead, tin, and zinc.

Extrusion offers a number of advantages over other metal manufacturing processes. Here are some:

- Efficient for mass production of long components with uniform cross-sections

- Low material waste and good control over dimensional tolerances

- Improves strength through grain structure alignment

However, the components obtained through extrusion may have rough finishing that requires additional processing. Moreover, if the process is not well controlled, it can lead to internal stresses or defects.

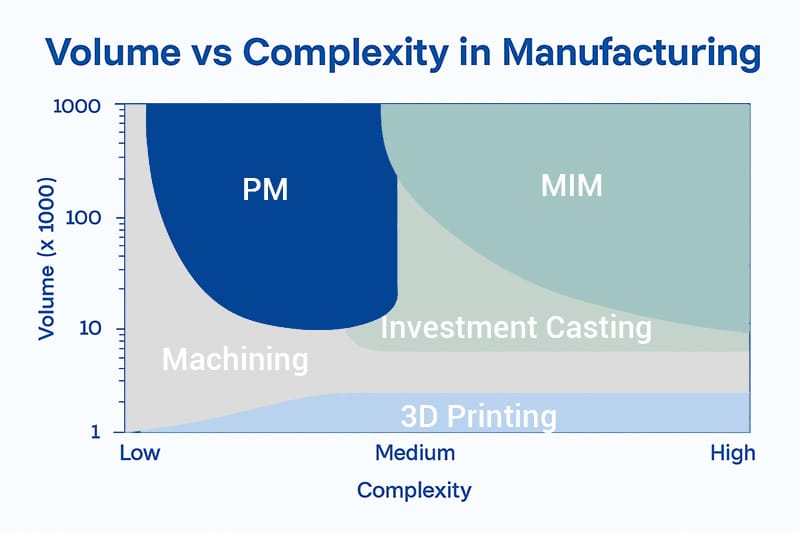

Each metal fabrication process serves its own niche. For small quantities, 3D printing is an ideal option as it doesn’t require molds and supports direct rapid prototyping. For large-volume production with controlled costs, such as oil pump gears, powder metallurgy is often a suitable choice. When both high shape complexity and production volume are required, as in folding screen mobile phone hinges, metal injection molding offers significant advantages.

The following table provides an in-depth comparison of different metal manufacturing processes.

| Attribute | PM | MIM | Forging | Casting | Machining |

|---|---|---|---|---|---|

| Material Selection | Medium | Limited | Medium | Limited | Wide |

| Shape Complexity | Medium | High | Low | Medium | High |

| Tolerance | Medium (±0.5%) | High | Medium | Medium | High |

| Surface Finish | Medium | Good (1 µm Ra) | Good | Medium | Good |

| Cost | Low | Medium | Medium | Low | High |

| Mass Production Feasibility | High | High | Medium | High | Low |

| Minimum Wall Thickness | 1 mm | 0.5 mm | 1 mm | 0.5 mm | 0.5 mm |

| Density | <95% | 94%–99% | 100% | 100% | 100% |