Metal injection molding (MIM) and metal 3D printing are advanced production technologies that have brought about a rapid shift in modern manufacturing.

Metal injection molding can create small and intricate components as tiny as 2 mm in diameter, while weighing less than 1 g without compromising dimensional accuracy and consistency.

On the other hand, metal 3D printing excellently fabricates complex and customized geometries that would be difficult or impossible to achieve using conventional manufacturing methods. This article aims to compare the strengths, limitations, and production processes of both methods.

Contents

What is Metal Injection Molding (MIM)?

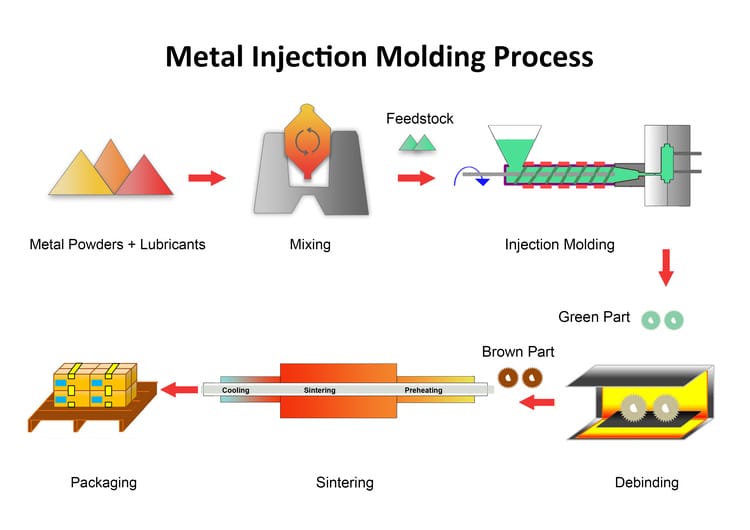

Metal injection molding process is a combination of powder metallurgy and plastic injection molding to produce small, complex metal parts with high strength. The process is carried out by four main steps.

Mixing

First, the feedstock is prepared by blending fine metal powders with a polymer binder, and the result is a homogeneous mixture (feedstock).

Injecting

Next, you feed the feedstock into an injection molding machine, then inject it into the mold, under high pressure, to create a “green part.”

Debinding

The following process is to debind the green part, and it requires removing the binders from the green part, leaving behind the metal. The process is done using either thermal, solvent, or catalytic methods.

Sintering

Finally, sintering happens by placing the remaining metal particles in a chamber under specific atmospheric conditions at a high temperature below the melting point of the material. This will fuse the particles to achieve the required density and strength similar to wrought metals.

What is Metal 3D Printing?

Metal 3D printing, also referred to as metal additive manufacturing (MAM), builds parts layer by layer from a digital model. The common techniques under this method include Selective Laser Melting (SLM), Direct Metal Laser Sintering (DMLS), and Electron Beam Melting (EBM). These processes fuse fine metal powders or other metal forms using high-energy sources such as lasers or electron beams. The fusing is usually done in an inert gas or vacuum environment, after which finishing steps like heat treatment or surface finishing are done.

Common materials used include stainless steel, titanium, aluminum, inconel, and cobalt-chromium. The choice depends on the application, mechanical properties, and performance demands.

Applications

MIM Applications

In the automotive industry, MIM is used in producing valves, gears, turbocharger components, and fuel system parts, for high strength and precision. The ability to mass-produce small complex parts makes MIM highly cost-effective for this sector.

For medical devices such as orthodontic brackets, surgical tools, and endoscopic instruments, MIM is ideal. This is due to the need for such parts to be miniaturized, biocompatible, and mechanically strong. MIM is used to produce consumer electronics where connectors, hinges, and smartphone components benefit from its capability to deliver fine details and thin walls at scale.

Metal 3D Printing Applications

In aerospace industries, components like lightweight brackets, fuel nozzles, turbine blades, and satellite parts are commonly 3D-printed. It is also used to restore antique components in aircraft. The medical and healthcare industries are a strong area for metal 3D printing to produce custom implants (dental, orthopedic, cranial). It also allows the production of functional metal prototypes like prosthetic hand gearbox parts and race-car linkages in automotive applications.

3D printing allows for the design and production of unique and intricate jewelry and decorative pieces. It is also used in robotics and automation to produce end-of-arm tooling or actuator parts that house sensors and cameras.

MIM vs Metal 3D Printing

Cost and Production Volume

MIM requires an initial investment in tooling, but once the mold is made, each part can be produced at very low cost. Therefore, MIM is highly competitive for large production volumes across different industry applications.

Contrary to MIM, Metal 3D Printing requires no initial tooling cost, so it is economical for prototypes or small batches. However, the material cost, machine time, and post-processing keep the cost high for each part, making it unsuitable for mass production.

Material Flexibility

MIM is compatible with a variety of materials, including alloys like stainless steel, copper, tungsten, cobalt, titanium, nickel-based materials, etc.

3D Printing supports many alloys, including titanium, aluminum, Inconel, and steels, and enables complex designs like lattices or internal channels.

Surface Finish

Metal Injection Molding (MIM) produces 17-4PH stainless steel parts with a smoother surface finish, typically Ra 1 µm as-sintered and about Ra 0.33 µm after surface treatment, according to a study on MIM surface finish. Therefore, MIM is well suited for products that demand a high-quality surface finish, such as watch cases, jewelry, and mobile phone camera brackets.

Metal 3D printing produces 17-4PH stainless steel parts with a rougher initial surface, typically Ra around 3–5 µm as-printed, but after surface treatment it can be reduced to about Ra 0.36 µm.

Speed and Lead Time

The speed and lead time of production can determine what method to choose. MIM has long lead times initially due to tooling development, but once molds are made, production is fast. 3D printing, on the other hand, offers fast turnaround for prototypes or small batches, without the need for tooling.

FAQ

What are the Differences in Materials between Metal Injection Molding and Metal Additive Manufacturing?

In Metal Injection Molding (MIM), powders are very fine (under 22 µm), near-spherical, and highly pure to prevent sintering defects. They are commonly made by gas or water atomization, or chemical reduction.

In Metal Additive Manufacturing (AM), powders are more spherical (over 98 % sphericity) and slightly coarser—15–45 µm for laser systems, 45–106 µm for electron beam. They must have ultra-high purity, typically produced by gas or plasma atomization.