Metal injection molding (MIM) is a modern manufacturing process that combines powder metallurgy process with plastic injection molding. It provides manufacturers with the freedom to create small, complex, and high-strength metal parts with precision, efficiency, and tight tolerances. This article explores the wide range of applications of MIM, the industries where it thrives, and why it has become such a critical process in modern manufacturing.

Contents

What is Metal Injection Molding (MIM)?

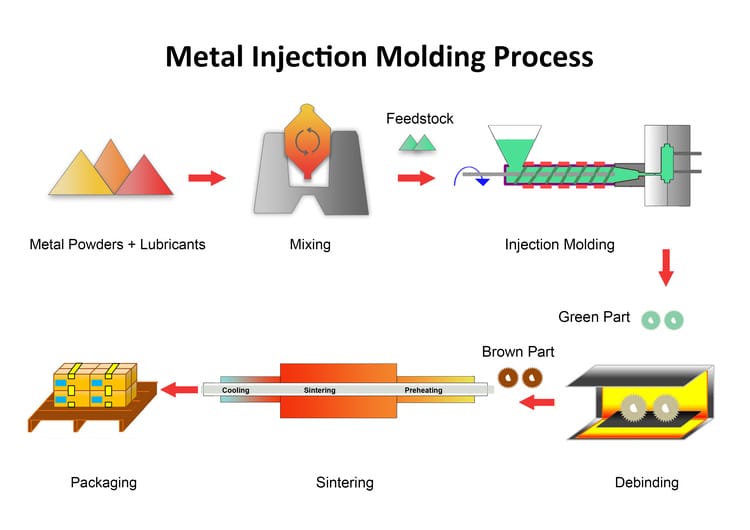

Metal injection molding process mixes metal powders with binders, forms green parts by injection molding, removes binders through debinding, and sinters to obtain dense, high-strength components.

Mixing

First, fine metal powders are blended with thermoplastic and wax binders, typically about 60:40 by volume. The blend is thoroughly mixed to achieve uniform coating of the metal powder with the binders. Afterward, the mixture is cooled, granulated, and prepared as feedstock for the injection molding machine.

Injection Molding

The feedstock is fed into the machine, where it is heated and injected into a mold cavity under high pressure to form a green part. It is allowed to cool, then ejected from the mold, and the process is repeated till the feedstock injection process is finished.

Debinding

Next comes debinding, a step where most of the binder material is carefully removed from the green part (which then becomes brown) via processes such as solvent extraction. Once debinding is completed, the part is left semi-porous enough for the remaining binders to escape during the sintering process.

Sintering

Finally, the brown part is placed in a furnace and sintered at high temperatures in a controlled atmosphere. During this stage, the remaining binders are removed, and the metal particles fuse together to form a dense solid. The resulting metal injection molded parts exhibit high density and mechanical properties such as strength, hardness and toughness that are comparable to wrought alloys.

Medical Applications

Medical devices often demand high precision, miniaturization, and biocompatibility, all of which MIM parts for medical applications deliver.

Surgical Instruments and Staplers

MIM is used to produce surgical instruments and staplers used for surgical procedures; these require intricate shapes, precision, high strength, and. The surgical instruments include forceps, clamps, scissors, and needle holders. MIM is ideal because the process ensures durability while maintaining lightweight structures that surgeons can handle with ease.

Orthodontic Brackets

In dentistry, orthodontic procedures are enhanced and efficient through the use of metal injection molding to produce orthodontic brackets. These brackets benefit from strength, precision, and biocompatibility.

Implants

MIM is also used to create implantable devices such as dental and orthopedic components, but their long-term application requires strict regulatory approval and additional biocompatibility validation. The implants are useful in dental, orthopedic, and drug delivery system applications. They include surgical bone screws, anchors, plates, etc

Endoscopic Components

The ability to create small, intricate, and complex geometries makes metal injection molding a perfect choice for the production of endoscopic tools used in minimally invasive surgeries. These devices or tools include graspers, biopsy forceps, etc.

Aerospace Applications

Aircraft Structural Components

n aerospace, MIM is applied to small precision components such as latches, fittings, and nozzles, where high strength and complex geometry are required rather than large primary structural elements. Thanks to its near-net shape capability, MIM mitigates the need for secondary machining, thereby providing precision while reducing production costs.

Aircraft components such as latches, fittings, spray nozzles, vane arms, and adjustment levers are created using MIM. Its ability to combine strength, reliability, and design complexity while minimizing waste makes it a top choice.

High-performance fasteners and connectors

Aircraft components such as seatbelt components, electrical connectors, and intricate fittings in wire-harness systems must be both reliable and resistant to fatigue. MIM delivers those qualities consistently by harnessing wider material options, including stainless steel, titanium, and superalloys. These ensure that the fasteners and connectors can withstand high stress despite their lightweight.

Automotive Industry Applications

Engine Components

MIM is used in automotive engines for complex small parts such as rocker arms, hydraulic spools, and fuel system components, though high-temperature turbocharger vanes are generally produced by casting superalloys. The process allows for intricate geometries such as splines, blind holes, knurled features, and integrated part assemblies without the need for multiple machining steps.

MIM reduces assembly time, streamlines production, and enhances the reliability of components by consolidating multiple parts into a single molded design.

Sensor Housings and Brackets

The automotive sector largely depends on sensors and electronic systems for safety, fuel efficiency, and driver assistance technologies. MIM produces housings, brackets, and intricate components used in ABS, seat belt mechanisms, and braking assemblies.

MIM materials provide homogeneous microstructures and isotropic properties, ensuring consistency in performance, durability, design flexibility, and tight tolerances. Electrical connectors, heat sinks, and fuel system housings are additional examples of MIM’s role in supporting modern automotive applications.

Electronics and Consumer Goods Applications

Metal Injection Molding plays a unique role in the production of consumer electronics and everyday devices. Smartphones include small yet critical components like lighting connectors (Apple devices), camera housings, cooling systems, buttons, and hinges that demand fine detail and precision.

Wearable devices, which must combine aesthetics with durability, and consumer goods applications like heat sinks and switches, are other areas where MIM excels. In electronics manufacturing, where space is limited, MIM provides the ability to pack strength into very small components without compromising performance.

Industrial and Tooling Applications

Industrial applications also demonstrate the versatility and material flexibility of Metal Injection Molding. Power tools components, valves, pumps, nozzles, and custom fasteners must endure heavy use while remaining cost-effective to produce. MIM is a key manufacturing process for industrial applications such as hydraulics, electronics, oil and gas, and safety equipment, where strength, precision, and long-term reliability are critical.

Custom fasteners used in heavy machinery and precision tools also demonstrate how MIM supports a wide range of industrial applications. Its adaptability can meet the diverse requirements of industries, and extends to production volumes, enabling manufacturers to produce both small and large-scale batches with affordable costs.

Sporting Goods Applications

MIM has also carved a role in sporting goods and related applications. that must be reliable under repeated use. Additionally. sporting gear such as archery equipment, golf wedges, cycling equipment, and outdoor tools are not left out. MIM produces these components with high precision, ensuring consistency and safety across large production runs.

FAQ

How Long Does a Metal Injection Molding Process Take?

The timing can vary depending on factors like production size, complexity of the part, material used, and MIM method applied. However, for a high-volume production run with a straightforward MIM method to produce simple parts, it could take from weeks to a few months to be completed.

What Are the Common Limitations of MIM?

Common limitations of MIM include:

- High cost of initial tooling or capital investment.

- Not suitable for small volume production runs due to its operational cost.

- Not a good option for producing very large and heavy parts.

- The process requires technical expertise because it depends on precise process control and involves many steps.