Metal Injection Molding (MIM) is a precision manufacturing process that combines plastic injection molding with powder metallurgy. It enables the production of small, complex, high-strength components with near-wrought density and excellent surface finish.

MIM offers clear advantages such as design freedom, efficient material use, and cost-effectiveness in high-volume production. However, it also has drawbacks, including high tooling costs, size limitations, and process complexity.

Contents

What is the Metal Injection Molding Process?

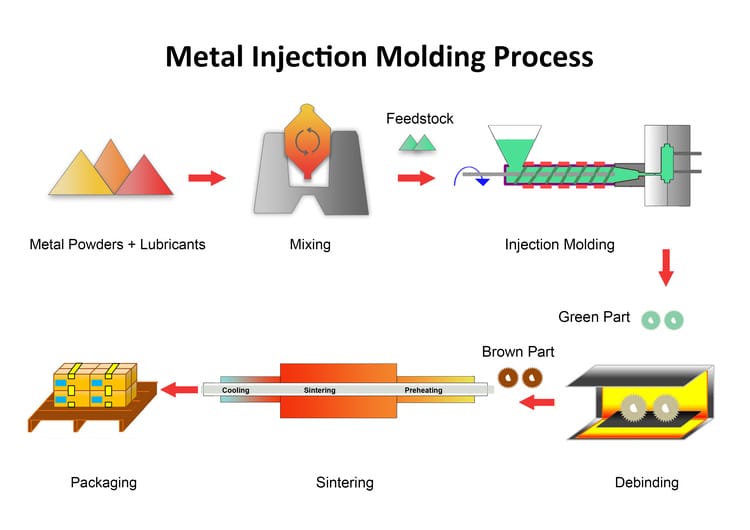

The metal injection molding process is carried out in four main steps:

Powder mixing

Ultra-fine metal powders, usually less than 20 μm, are mixed with thermoplastic and wax binders. The mixture contains about 60% metal and 40% binder by volume. It is blended until uniform, then pelletized. This makes the feedstock flow consistently during molding

Injection Molding

The feedstock is heated and injected under high pressure into a precision mold cavity, forming a green part. At this stage, the part has the intended geometry but lacks structural integrity.

Debinding

Binder system is partially or fully removed through solvent, catalytic, or thermal debinding methods. The result is a fragile brown part with controlled porosity, allowing gases to escape during sintering.

Sintering

Then, the brown part is placed in a high-temperature furnace with a controlled atmosphere. In this stage, the remaining binder burns off. The metal particles bond through solid-state diffusion. The part densifies to about 95–99% of its theoretical density. The finished component shows strength and toughness similar to wrought alloys. It also offers high dimensional accuracy and a fine surface finish.

Advantages of Metal Injection Molding

Design Flexibility and Miniaturization

- MIM provides design flexibility through the freedom to create and produce complex and intricate shapes.

- It eliminates the need for assembly processes like joining or welding because it offers the option for merging assemblies of a compound component into a single piece.

- Metal injection molding is ideal for miniaturization because it is well-suited for producing small components that require precision.

Material Utilization

- Meta injection molding minimizes waste by using up to 95% of the material.

- It is cost-effective, especially when working with exotic materials like titanium alloys, superalloys, or refractory metals, due to its level of material utilization.

Density and Mechanical Performance

Metal injection molding parts reach about 98% density, close to wrought alloys. Their high density improves fatigue resistance, hardness, and durability, making them reliable for demanding applications.

Cost-Effectiveness in High-Volume Production

Metal injection molding is well suited for mass production of near-net-shape components. It lowers costs by minimizing secondary machining and post-processing. The process is highly adaptable to automation, supports repeatability, and delivers consistent quality across large production runs.

Surface Finish and Dimensional Precision

Metal injection molding produces components with a fine surface finish that can reach Ra 0.8 μm. It is ideal for the manufacturing of products with high requirements on appearance, such as folding mobile phone hinges and mobile phone camera brackets

Disadvantages of Metal Injection Molding

High Initial Costs and Tooling Investment

Metal injection molding requires significant upfront spending on molds and specialized equipment. The tooling is complex and costly to manufacture, which makes the process capital-intensive at the start. These expenses must be spread across large production volumes to achieve economic efficiency.

Size Limitations

Metal injection molding is constrained by mold and furnace capacity, so it is best suited for small to medium components, usually under 100 grams. Larger parts require longer processing cycles, which drives up production costs and reduces efficiency.

Material Restrictions

There is a limited choice of materials that can be used for metal injection molding, because not all metals are suitable for this manufacturing method.

Sintering Shrinkage

MIM parts shrink about 15–20% during sintering. While this densifies the material, it also complicates dimensional accuracy. Without proper mold oversizing and process control, the final parts may show size variation or fall outside tolerance limits.

MIM vs. Other Manufacturing Methods

| Features | Metal Injection Molding (MIM) | CNC Machining | Additive Manufacturing (3D Printing) | Casting |

|---|---|---|---|---|

| Material waste | Very low (near-net shape, high material utilization) | High (subtractive process) | Low, but support structures add waste | High (gating, risers, excess metal removed) |

| Near-net shape | Excellent dimensional accuracy | High precision, but subtractive | Achieved but limited by layer resolution | Requires machining/finishing |

| High-volume production | Very suitable, cost-effective | Not suitable; costly and time-intensive | Not suitable; high cost and limited scalability | Suitable and cost-effective at scale |

| Low-volume production | Not ideal; tooling cost too high | Suitable and efficient | Suitable for prototypes and low runs | Possible but less economical for very small runs |

| Part size suitability | Best for small components (typically <100 g) | Flexible for both small and large parts | Limited by machine build volume | Widely used for large parts |

| Complex geometries | Excellent; supports intricate designs | Possible but expensive | Excellent; extreme design freedom | Limited; complexity increases cost/defects |

| Design freedom | Very high | Moderate | Extremely high | Limited |

| Surface finish | Excellent; minimal post-processing | Excellent; precise machining finish | Variable; may need finishing | Moderate; often requires machining |