Liquid Phase Sintering (LPS) is a sintering process where a liquid phase forms during the sintering of a powder compact, facilitating densification and bonding of solid particles.

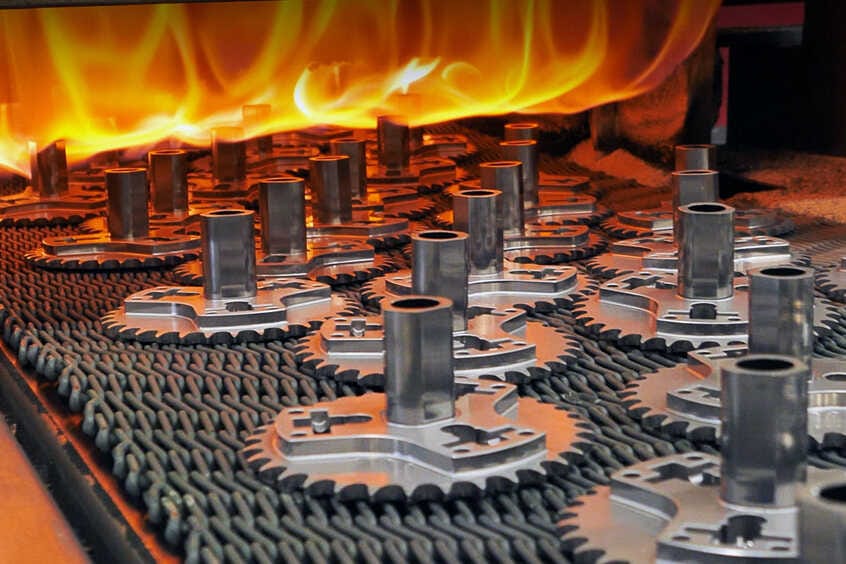

This process is used to sinter the components with high melting points that are difficult to sinter with traditional solid state sintering. The main purpose of LPS is to accelerate densification. Grain growth may occur as a side effect and must be controlled.. LPS is now widely used by engineers to manufacture high-temperature bearings, automobile engine connecting rods, and electronic capacitors.

Contents

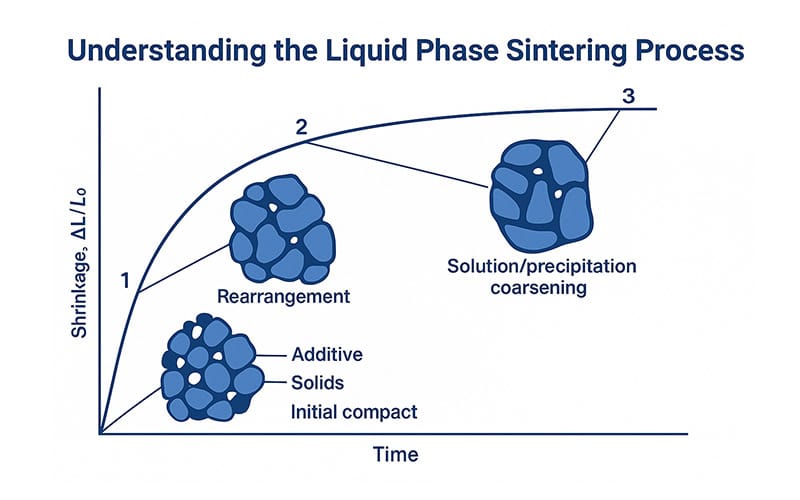

Understanding the Liquid Phase Sintering Process

Liquid phase sintering is basically done to enhance the densification of components. The process takes place in three stages of structural changes in which initially the component undergoes sintering, just like the solid-state sintering, before reaching their melting temperature. After one of the liquids reaches its melting temperature and gets liquified, the three main processes occur here:

Rearrangement Stage

It’s the initial stage when one of the materials liquefies and flows between the solid particles due to capillary action. This flow leads to rearrangement and densification as the liquid particle fills the empty spaces between solid particles. The optimal liquid volume depends on the material system typically 5–15% volume is used.

Solution-Reprecipitation Stage

After the rearrangement, the small solid particles also begin to dissolve into the liquid, and larger particles are formed. This phenomenon occurs according to Ostwald ripening. This step helps reduce voids and improve density by gradually reshaping grains into more compact forms.

Final Densification Stage.

At this stage, the material develops a rigid, solid structure. Here, further densification continues through solid-state diffusion to close any remaining pores and increase overall density. This step is similar to the final phase of traditional solid-state sintering.

Types of Liquid Phase Sintering

Permanent Liquid Phase Sintering

If the liquid phase is maintained throughout the sintering process such sintering is termed as permanent liquid phase sintering. This continuous presence of liquid phase not only enhances the densification of your material but also improves mechanical properties. It is typically used for cemented carbides and tungsten carbide tools.

Reactive Liquid Phase Sintering

This type of liquid phase sintering occurs through exothermic chemical reactions between dissimilar powders that generate a liquid phase during sintering. These reactions here are responsible for the densification of the component.

Transient Liquid Phase Sintering

In transient LPS, additive powders melt during heating. It forms a temporary liquid that completely dissolves into the solid matrix over time. Here the amount of liquid depends on variables like heating rate and particle size. It is considered Ideal for maintaining dimensional stability in precision components.

Application of Liquid Phase Sintering

Cutting Tools

Liquid phase sintering with tungsten carbide combined with cobalt systems is commonly used for machining tools. These materials provide hardness and toughness to the components.

Bearings and Wear Parts

LPS systems like Cu-Sn and Al-Pb offer high resistance to wear and tear. As a result, they are used to manufacture components that are applied in oil-less and high-wear environments.

Electronics

Liquid phase sintering also found their application in electronics such as capacitors, resistors. Here the LPS system, like BaTiO₃–LiF and Ag–Hg, is used due to its excellent dielectric properties.

Automotive and Aerospace

Since liquid phase sintering offers a high level of purity and precision in the components, that is why it is widely used for manufacturing components in the aerospace and automotive industries.

Refractories and Turbines

LPS in which materials like Al₂O₃–SiO₂ and Si₃N₄–Y₂O₃ are used for manufacturing components with high resistance to temperature. These are used in high-temperature applications like steelmaking and turbine components.

Advantages and Disadvantages of Liquid Phase Sintering

Advantages of Liquid Phase Sintering

Lower Sintering Temperature

Liquid phase sintering allows materials to be processed at temperatures significantly lower than their melting points. This results in lower energy use, reduced processing costs, and minimized risk of thermal damage to sensitive materials.

Improved Densification

In liquid phase sintering process, the liquid phase fills gaps between solid particles; this results in tighter packing and eliminating pores. As a result, stronger, more durable components are formed, which are considered ideal for load bearing and wear-resistance applications.

Better Microstructure Control

Since the grain growth and porosity can be controlled in LPS due to the presence of a liquid phase, it enables consistent material properties. This reduces the need for additional machining.

Difficult-to-Densify or High-Melting-Point Materials

LPS is especially useful for materials that are difficult to densify using traditional sintering methods. Such as the material with high-melting-point metals and advanced ceramics.

High Purity and Uniform Properties

During liquid phase sintering process, sintering conditions can be controlled, as a result uniform microstructures and pure components are manufactured.

Superior Mechanical Strength

With the help of LPS you can produce highly dense and refined microstructures with enhanced mechanical performance of materials. That is why LPS is used to manufacture robust parts such as cutting tools, engine components, and structural hardware.

Limitations of Liquid Phase Sintering

Shape Distortion (Slumping)

If the ratio of materials is not controlled and too much liquid forms during sintering, it can lead to the distortion in the shape of components.

Difficult Process Control

In LPS, both microstructural changes and final structure are affected by the parameters such as heating rate and liquid content. That’s why it is very crucial to control these parameters.

Complex Multi-Phase Interactions

In LPS, the presence of solid, liquid, and vapor phases introduces complex behavior due to different solubilities, viscosities, and diffusion rates, along with interfacial energies.

Reduced Predictability

Since in LPS the sintering occurs very quickly and includes multiple variables, as a result, it’s harder to predict and model than solid-state sintering.

Solid State Sintering vs Liquid Phase Sintering

Here is the comparison between solid state sintering and liquid phase sintering.

| Aspect | Liquid-Phase Sintering (LPS) | Solid-State Sintering (SSS) |

|---|---|---|

| Sintering Mechanism | A liquid phase forms from additives and assists densification through capillary action. | Occurs entirely in the solid state via diffusion-driven mass transport. |

| Temperature Requirement | Lower due to presence of liquid. | Higher temperatures are required to activate diffusion. |

| Densification Rate | Faster due to liquid-assisted particle rearrangement. | Slower, limited by solid-state diffusion mechanisms. |

| Microstructure | May result in complex microstructures with secondary phases. | Typically more uniform with controlled grain growth. |

| Advantages | Lower energy use, accelerated densification, ability to sinter otherwise difficult materials. | Simpler process, predictable microstructure, lower distortion risk. |