Jaw Coupling Hub

BLUE supplies a wide range of standard jaw coupling hubs at competitive prices for use in motors, pumps, and general machinery. Our hubs deliver consistent quality, excellent wear resistance, and high precision.

Why Choose BLUE?

We have established ourselves as a trusted supplier of jaw coupling hub, providing free mold design service, fast shipping, and competitive prices from China.

BLUE High Quality Standards

BLUE assurethe quality of your flexible jaw couplings with an ISO 9001:2015 certified quality management system. Free jaw coulping hub samples are available for testing.

Standard Jaw Coupling Hub

BLUE has a wide range of standard jaw type coupling hubs in stock for fast delivery. Visit our standard parts shop to find the exact match for your applications.

Free Mold Design Service

With over 20 years of expertise in mold design, BLUE offers free, high-precision mold design services to meet your customized needs. Let our experience work for you!

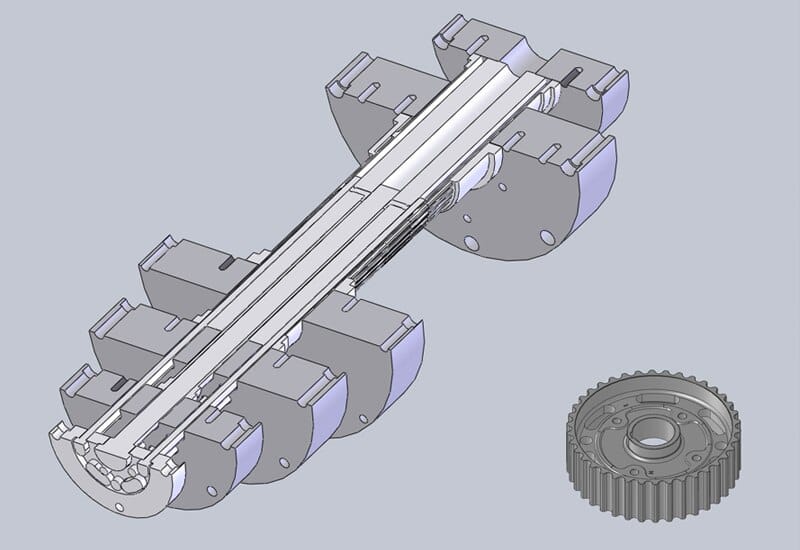

What is a Jaw Coupling Hub?

A jaw coupling hub is one of the two metal pieces in a jaw coupling that connect to the driving and driven shafts. Each hub has curved “jaws” that fit around an elastic insert (called a spider). When the hubs rotate, the jaws press against the spider to transmit torque.

In simple terms, the hub is the shaft-mounted half of a jaw coupling. It holds the jaws, connects to the shaft with a keyway or set screw, and works with the spider to absorb vibration, reduce shock, and compensate for small misalignments.

How Jaw Coupling hubs Work?

Jaw coupling hubs work by transferring torque through the compression of the elastic spider. As the driving shaft turns, its jaws push against the spider, which then delivers the force to the jaws on the opposite hub. This creates smooth, continuous rotation between the two shafts.

The elastic spider cushions impact and reduces vibration, preventing direct metal-to-metal contact between the hubs. This design also allows the coupling to accommodate small angular, parallel, and axial misalignments while maintaining stable power transmission.

Applications Jaw Coupling Hubs

Jaw coupling hubs are utilized in small to medium-power machinery where smooth torque transmission and vibration damping are important. They are widely applied in pumps, compressors, blowers, conveyors, mixers, and gearboxes.

Jaw coupling hubs are also common in motor-driven equipment such as electric motors, stepper motors, and servo systems. The elastic spider helps reduce shock loads during start-up and protects the connected shafts.

In factory automation, packaging, printing, and material-handling equipment, jaw coupling hubs are valued for their compact size, flexibility, and easy maintenance.

Jaw Coupling Made by Powder Metallurgy

Jaw coupling hubs can be produced by the powder metallurgy process using FC-0205 iron-copper steel. The process begins with powder mixing, where FC-0205 base powder is blended with binders to improve flow and compaction. This mixture is then pressed in a precision die to form the jaw profile and shaft-mounting features in one step.

After compaction, the green parts are sintered at controlled temperatures about 1120℃ to bond the particles and achieve the required strength and dimensional stability. Depending on performance needs, sizing or machining may be applied to improve tolerances. This PM route provides consistent geometry, good fatigue strength, and cost-effective mass production for jaw coupling hubs.

Standard Jaw Coupling Hub Specifications

We have a wide range of jaw coupling parts for quick delivery. You can choose what exactly match your prokects.

| Attribute | Value |

|---|---|

| Bore Size (mm) | 3, 6, 9, 12, 15, 19 |

| OD | 16, 28, 35, 45, 54, 64.5, 85, 96, 115, 127 |

| Length | 6.6, 15.6, 19, 21, 25.5, 27, 35, 43, 45, 54, 64 |