Jaw Coupling Manufacturer - BLUE

BLUE offers you 100+ standard jaw couplings with no tooling fees, applied in motors, pumps, and machinery. Our jaw coupling parts, including hubs and spider inserts, feature high precision and good strength.

Why Choose BLUE?

We have established ourselves as a trusted supplier of jaw couplings, providing free mold design service, free samples, fast shipping, and competitive prices from China.

BLUE High Quality Standards

BLUE assurethe quality of your flexible jaw couplings with an ISO 9001:2015 certified quality management system. Free samples are available for testing.

Standard Jaw Coupling Shop

BLUE has a full range of standard jaw type couplings in stock for fast delivery. Visit our standard parts shop to find the exact match for your applications.

Free Mold Design Service

With over 20 years of expertise in mold design, BLUE offers free, high-precision mold design services to meet your customized needs. Let our experience work for you!

BLUE Jaw Coupling in China

BLUE offers a range of standard claw couplings, known for their high precision, mechanical strength, and long service life.

Jaw Type Couplings

A jaw type coupling is a flexible coupling that connects two shafts, accommodating misalignment and damping vibrations.

Jaw Flex Coupling

Claw-type flexible coupling is a flexible mechanical coupling commonly used in power transmission systems such as motors, pumps and industrial machinery.

Jaw Clutch Coupling

BLUE claw clutch couplings have long service life, strict tolerances and are available in a variety of sizes.

L jaw Coupling

BLUE L jaw couplings enable smooth transmission of torque between the shafts, reducing the risk of torque fluctuations.

Flexible Jaw Coupling

BLUE flexible claw couplings can handle certain angular misalignments and slight parallel misalignments between shafts.

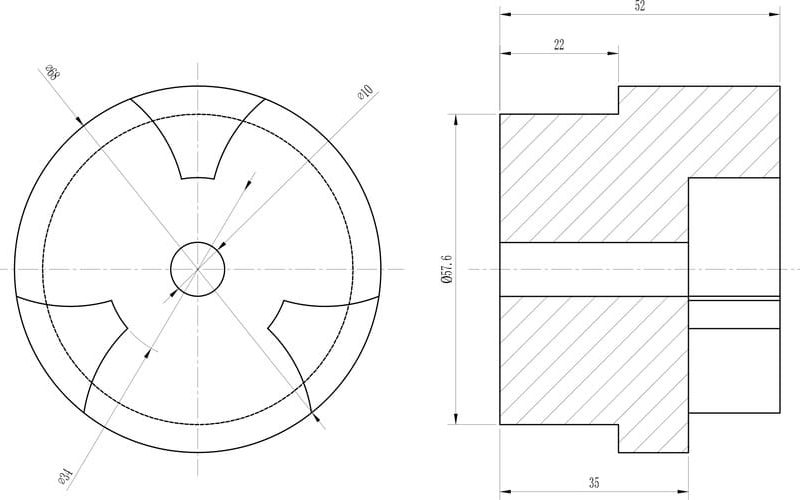

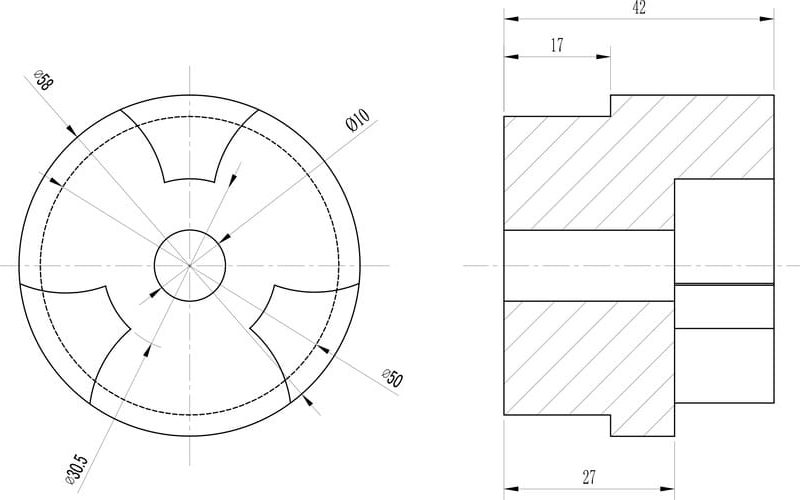

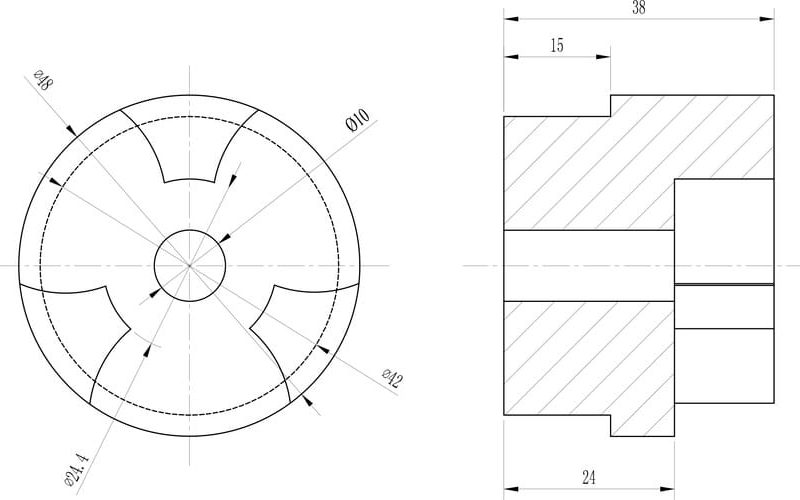

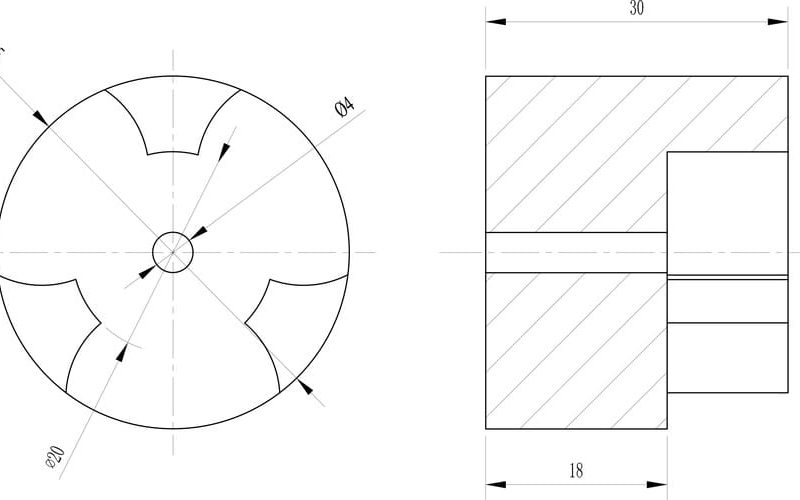

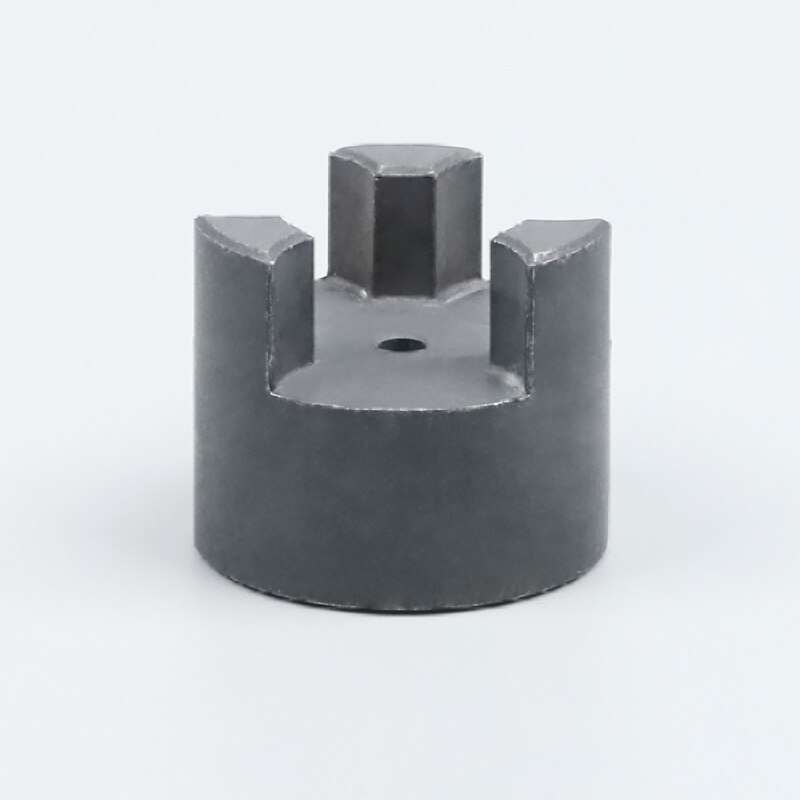

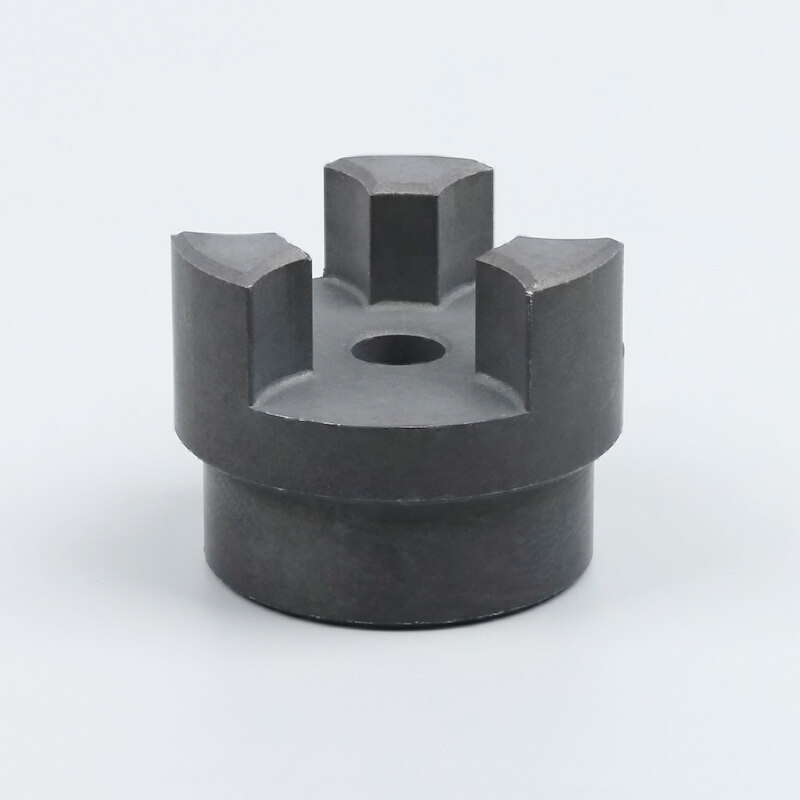

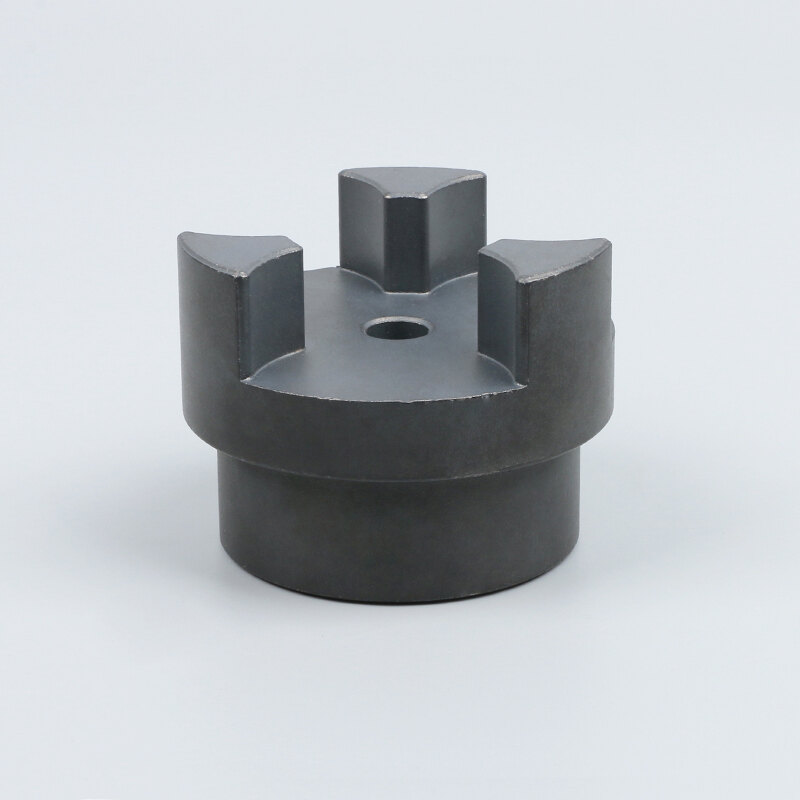

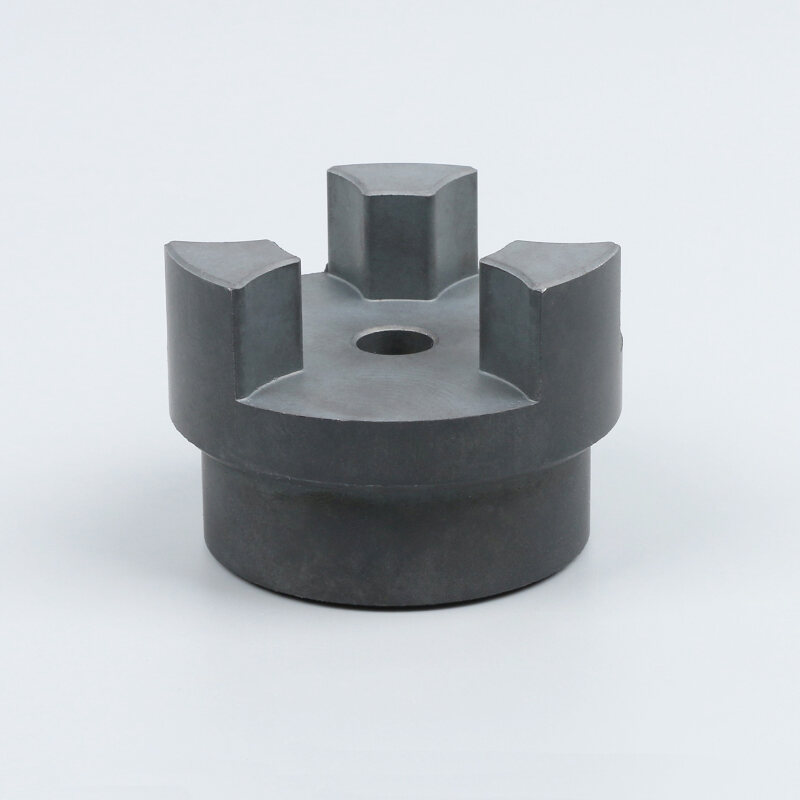

Jaw Coupling Hub

BLUE jaw coupling hubs are made of iron-based metal powder, which has excellent mechanical strength and tight tolerances after sintering.

What is a Jaw Coupling?

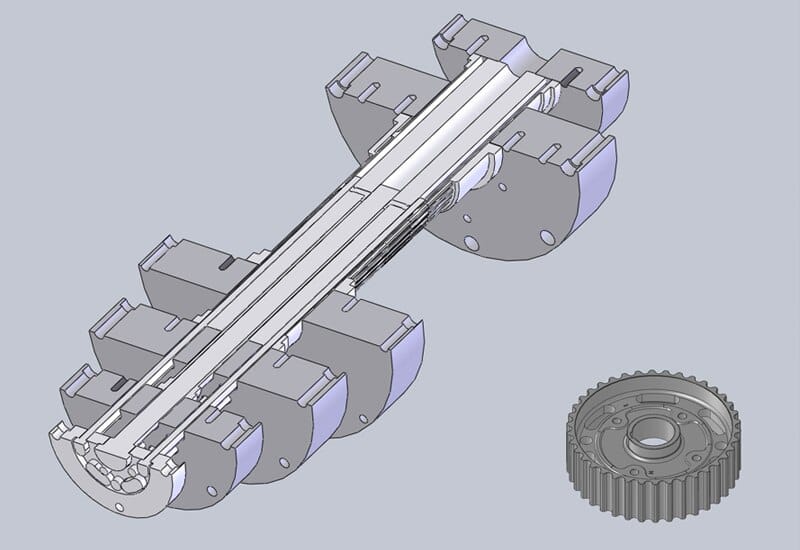

A jaw coupling is a flexible shaft coupling that connects two rotating shafts while reducing vibration and handling small misalignments in a power transmission system. It is made of two metal hubs with curved jaws and an elastomer insert called a spider. During operation, the jaws press against the spider to transmit torque, and this compression helps absorb shock loads, reduce noise, and protect the motor and bearings from excess stress.

The design is simple and reliable. The spider can be replaced quickly when worn, and if it fails completely, the two hubs can still make limited metal-to-metal contact which allows the machine to keep running instead of stopping suddenly. Because it combines vibration damping, durability, and easy maintenance, a jaw coupling is widely used in pumps, compressors, conveyors, and many other types of industrial machinery.

Jaw Couplings Produced by Powder Metallurgy

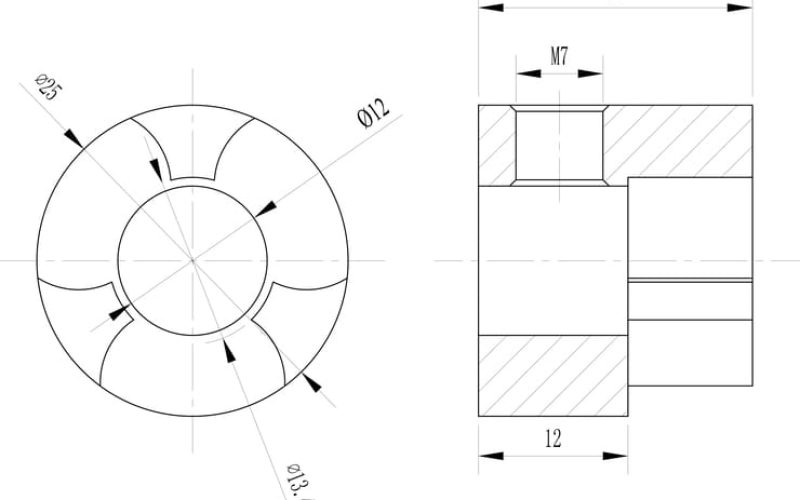

Jaw couplings can be produced using the powder metallurgy process, which forms the jaw geometry directly from metal powder and creates a dense and durable component after sintering. This method is well suited for the curved jaw profile because it delivers accurate tooth engagement and stable concentricity, both of which are important for smooth torque transfer through the elastomer spider.

In manufacturing, iron or steel powders are compacted in a precision die that defines the overall shape of the coupling, including the jaws and the internal bore. The green compact is then sintered in a controlled atmosphere to achieve the required strength and wear resistance. Additional steps such as sizing or heat treatment may be used to improve dimensional accuracy and mechanical performance. After these processes, the metal parts are assembled with an elastomer insert to form a complete jaw coupling.

Powder metallurgy offers clear benefits for producing jaw coupling components. It supports near-net-shape forming of complex jaw profiles, minimizes material waste, and delivers consistent mechanical properties suitable for continuous industrial operation.

BLUE Jaw Coupling Advantages

BLUE is an ISO 9001:2015 certified supplier, providing you with high-quality jaw couplings.

Our jaw coulpings have high accuracy and can accommodate parallel misalignment up to 0.015 inch and angular shaft misalignment up to 1 degree.

BLUE offers jaw coupling parts, including the jaw coupling hub and spider insert.

Our jaw couplings are available in custom sizes, shapes, and materials.

Standard Jaw Coupling Supplier

We have a wide range of jaw coupling parts for quick delivery and no mold fees required.

Standard jaw type coupling bore sizes (mm): 3, 6, 9, 12, 15, 19.

Standard jaw type coupling OD (mm): 16, 28, 35, 45, 54, 64.5, 85, 96, 115, 127.

Standard jaw type coupling hub length (mm): 6.6, 15.6, 19, 21, 25.5, 27, 35, 43, 45, 54, 64.

Benefits of Jaw Coupling

Claw couplings can accommodate shaft angle and parallelism deviations, reducing the risk of damaging other parts.

The claw coupling’s elastic spider absorbs shock and vibration, protecting the connected equipment.

They can efficiently transmit high torque without slipping, enabling high torque transmission.

If the elastic insert fails, the interlocking claws of the coupling hub maintain torque transmission and continue to operate.

Applications of Jaw Coupling

Motors and Pumps: Jaw coupling used in connecting motors to pumps, compressors, and other machinery equipment.

Conveyors: Jaw couplings help transmit power in conveyor systems, compensating for shaft misalignment and reducing wear.

Agricultural Machinery: Jaw couplings efficiently transmit power and are often applied in agricultural equipment such as tractors, textile machines, harvesters, and irrigation systems.

Standard Jaw Coupling Specifications

Here are BLUE’s production capabilities for jaw type couplings, including density, hardness, tolerance and diameter range, surface treatment, etc.

| Attribute | Value |

|---|---|

| Material | FC-0205. FC-0208, FD-0205, FN-0208 |

| Density | 6.6-6.9g/cm3 |

| Hardness | 65-90 HRB |

| Surface Treatment | Steam Treatment, Dacromet |

| Outer Diameter | 16 to 127 mm |

| Length | 6.6 to 153.4 mm |

| Standard Bore | 3 to 19 mm |

| Tolerance | ±0.01 mm |