Powder metallurgy is amnufacturing process that utilises powder metal and compacts it into the desired shape components instead of using molten processing. It enables the processing of those metals that are difficult to cast or melt, such as platinum and tungsten. With the passage of time, powder metallurgy process has made a market in the industries that require high precision, material efficiency and unique properties that are difficult to achieve by traditional methods.

Contents

Ancient Foundations of Powder Metallurgy

The use of metal powders is not new. Archaeologists have found evidence that people were shaping items from powdered metals as far back as 3000 B.C.Many ancient cultures, including the Egyptians and the Incas, used powder metals such as gold and copper for manufacturing jewellery and decorative objects. Although they were not aware of precise tools and equipment, they used simple techniques of heating and pressing the powder together. Their work showed that metal could be worked without fully melting it by using their powder.

Early Scientific Contributions

In the 1700s, Russian scientist Mikhail Lomonosov experimented with turning metals like lead into powder and then heating them back into solid form. Another major step toward modern powder metallurgy was the work of Peter G. Sobolevsky in 1827. He introduced the manufacturing of platinum objects by using a controlled powder process.

Modern Era of Powder Metallurgy

W. H. Wollaston and Platinum Sponge (Early 1800s)

One of the earliest documented commercial applications of powder metallurgy was William Hyde Wollaston’s work (c. 1801–1805) producing malleable platinum by pressing and sintering platinum sponge; In his work, he produced workable platinum by pressing and sintering platinum sponge without the need for extreme temperature. At that time, melting the platinum was a challenge and nearly impossible using the furnace available at that time due to its high melting temperature.

Tungsten Filaments (1909)

Tungsten is another metal with a very high melting point, which is very difficult to melt and process through conventional casting. In 1909, powder metallurgy enabled the production of tungsten filaments for incandescent light bulbs.

Cemented Carbides (1920s–1930s)

During the 1920s, powder metallurgy advanced again with the invention of cemented carbides like tungsten carbide. These materials replaced the traditional steel due to their higher strengths and wear resistance in machining and cutting tools. By the 1930s, carbide tools became standard in industries requiring durability and precision.

Self-Lubricating Bearings (1930s)

The porous self-lubricating bearings were also developed in the 1930s by using sintering powdered metals with small, controlled pores. The self-lubricating ability of these bearings resulted in decreased friction and maintenance, making them widely used in automotive and machinery applications.

Structural Parts (1940s–1960s)

During the mid-20th century, especially in the 1940s–1960s, the use of powder metallurgy expanded to a remarkable extent as a mass production technology. It enabled the manufacturer to produce complex structural parts for the automotive and tooling industry through iron or steel-based metal powders.

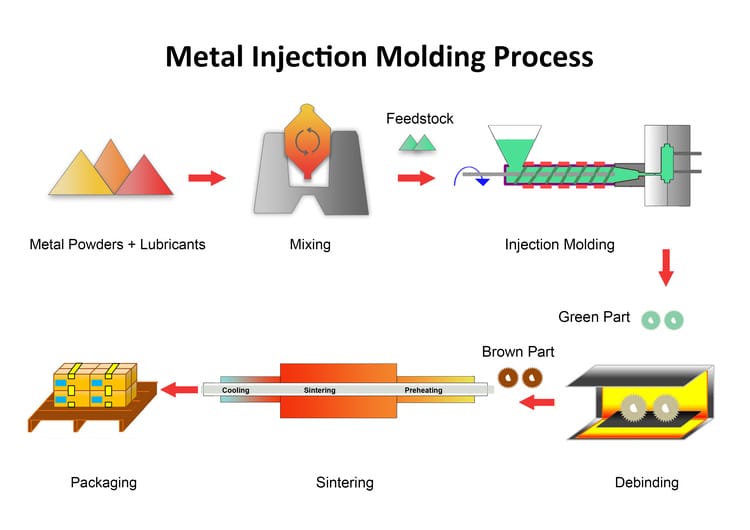

Metal Injection Moulding (1970s)

In the 1970s, metal injection molding (MIM) emerged, combining plastic injection moulding with powder metallurgy. Fine metal powders were mixed with a binder, shaped like plastic, and then sintered into dense, complex components. MIM made it possible to produce small, intricate parts with excellent mechanical properties for industries like aerospace, medical, and electronics.

Powder Forging (1980s)

Later in the 1980s, powder forging was applied to automotive parts, particularly connecting rods. This method involved compacting metal powders, sintering them, and then forging to achieve high density and strength. Powder-forged connecting rods became widely adopted in vehicles due to their durability and cost-effectiveness compared to fully machined steel.

Future Advances in Powder Metallurgy (1990s–today)

Warm Compaction

An advancement in powder metallurgy technique is warm compaction, which was introduced in the 1990s. In warm compaction, manufacturers use ~100–150 °C to raise green density and strength, heated powders and dies to achieve higher-density parts than traditional press-and-sinter. y, making it especially useful in automotive gears and structural applications.

Sinter Hardening

Unlike the traditional PM process, sinter hardening enables the production of high-precision components by combining sintering and heat treatment into one step. This not only results in the reduction of production costs but also improves mechanical properties like hardness and wear resistance of the components. It allows manufacturers to replace more expensive forged components with powder metal alternatives, especially in transmission and heavy-duty parts.

Additive Manufacturing

3D printing with metal powders, also called additive manufacturing, has become one of the most significant advances in recent decades. Unlike traditional compaction methods, it builds parts layer by layer, enabling complex geometries that were previously impossible. Industries such as aerospace and medical implants have adopted this technology for lightweight, custom components.

Soft Magnetic Composites (SMCs)

Soft magnetic composites are engineered powders designed for electrical applications, particularly in motors and transformers. They offer

- Reduced energy losses

- 3D design flexibility

- Improved performance over laminated steel

Today, SMCs play an important role in the development of high-efficiency electric motors, which is a growing need for electric vehicles.