BLUE | Free Mold Design Service

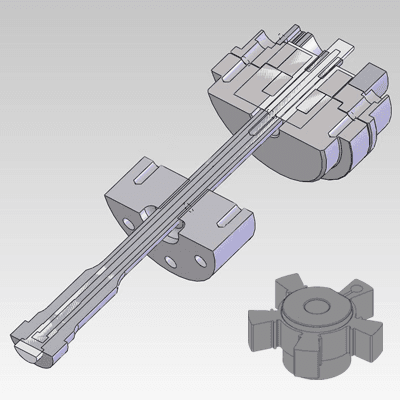

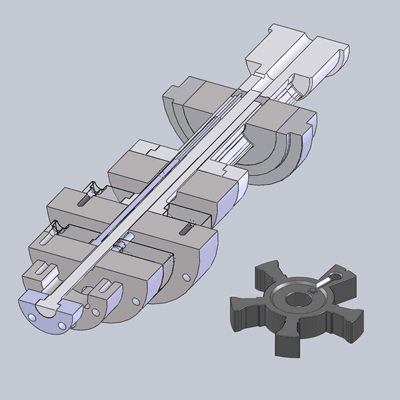

BLUE has more than 20 years of experience and in-depth technology in designing and machining powder metallurgy molds, including oil pump gears & rotors, pulleys, flanges, etc.

BLUE's Mold Design & Machining Capabilities

BLUE has a professional and experienced team to help you design molds. High quality is our top priority, closely supervising every process to ensure that your molds meet tight tolerances.

20+ Years Experience

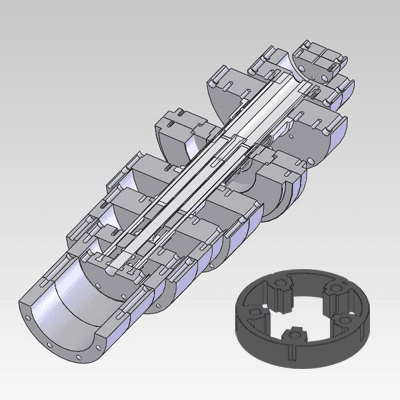

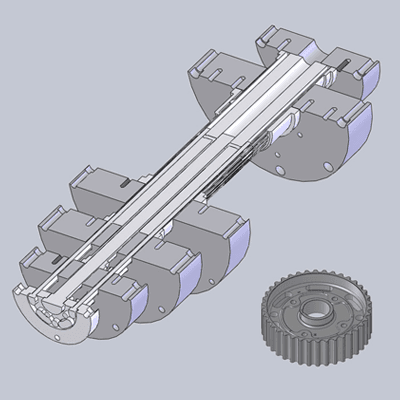

BLUE specializes in designing molds for products like water pump pulleys, oil pump rotors & gears, oil-impregnated bushings…

Return Designed Drawing

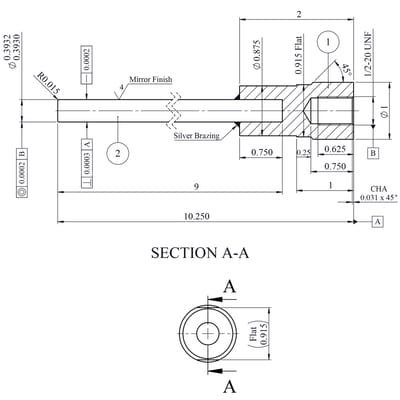

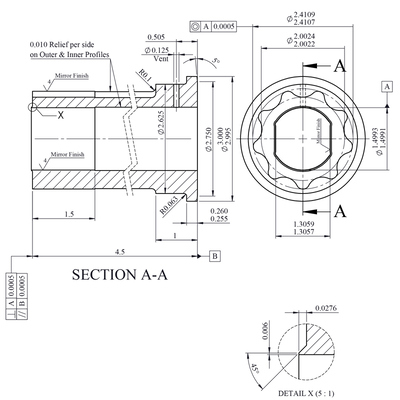

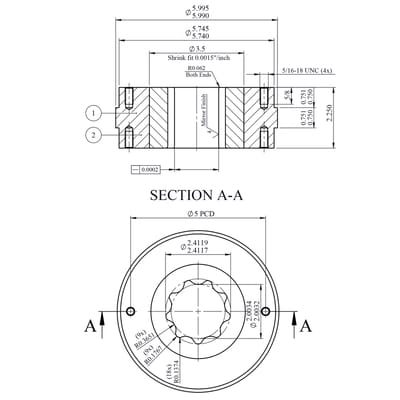

We will provide you with the 2D drawings of the design for your review and subsequent modification.

Mold Machining Service

BLUE has advanced mold manufacturing capabilities to meet strict tolerances and pefect surface finish.

Powder Metallurgy Compacting Mold

We specialize in designing molds for complex-shaped parts, including upper and lower punches, die, and core rod. With our expert mold design, you can efficiently mass-produce high-quality products.

The molds we manufacture have a dimensional tolerance of ±2μm, a surface finish of Ra0.2-0.4μm, and position accuracy within 3μm.

When we design your mold, we will take into account the expansion during demoulding, the shrinkage or expansion during sintering, and the reserved amount of sintered products, etc.

Powder Metallurgy Sizing Mold

Powder Metallurgy Mold Accessories

Along with powder metallurgy compacting and sizing molds, we can also provide a range of powder metallurgy mold accessories, including:

- Upper punch support plate

- Guide pillars

- Die template

- Die holder

- Bottom mold base

- Sliding plate

- Core rod fixing ring

- Core rod support plate

Powder Metallurgy Mold Processing

We provide a one-stop service from design to production, saving you the time and effort of overseeing complex projects while also offering competitive prices.

BLUE is equipped with high-precision processing machines such as AGIE CLASSIC W-EDM, AGIE P350 EDM, and TOYODA grinding machines. This ensures that all molds meet the size and tolerance requirements specified in the drawings.

BLUE is dedicated to providing clients with the highest level of quality, and we try our best to carefully control every process.

Various Powder Metallurgy Molds Designed by BLUE

We use SolidWorks, ProE, UG and AutoCAD software when designing your mold.

BLUE Powder Metallurgy Mold Production Equipment

We have a range of molding making equipment such as EDM, Wire Cutting Machine, CNC Grinding Machine, Turning, CNC Machine center, etc.

Find Out How BLUE Saves Your Time

BLUE offers a full range of powder metallurgy standard parts to customers worldwide, along with online ordering, free design, and mold manufacturing services. All sintered parts pass stringent inspections to ensure high and consistent quality.

BLUE Quality Standards

BLUE ensures top-quality products through strict internal quality control, ISO 9001:2015 certification, and secure packaging.

Standard Parts Shop

No mold fees for all standard powder metal parts, easy to online selection, and free samples prior to ordering.

OEM/ODM Services

Using advanced equipment, we provides free mold design based on your drawing and offers assistance with product processing.

FAQ's

Here are some of the questions we get asked often. If yours isn’t answered, don’t hesitate to contact us, we’re happy to help!

The die cavity needs to have high strength, high hardness and good wear resistance. Most powder metallurgy die inner rings generally use D2, M2, SKD11, CPMV10, C11.

Upper and lower punches need to have excellent toughness and fatigue resistance. Therefore, most materials use tool steel, such as A2, SKD11, SKD12, DRM2.

The core rod is long and therefore must have good tensile strength. We use high tensile strength tool steel, like SKH9.

The production cycle is related to the complexity of the design, the size of the mold, and the materials used.

Our mold design can usually be completed within 3 days. Normally, it takes 10-20 days to manufacture the mold. We will try our best within 15 days.

The powder metallurgy molds manufactured by BLUE can press approximately 500,000 pieces.