Sintered Door Lock Part Manufacturer - BLUE

We supply a wide range of standard sintered door lock parts for residential locks, commercial locks, and fire doors, all without mold fees. Our sintered door Lock Parts include lock bolts,lock cylinders, lock levers, and lock pins

Why Choose BLUE?

BLUE is your trusted manufacturer of door lock parts, certified to ISO 9001:2015. We keep standard parts in stock, and you can visit our shop to find the exact match for your needs.

BLUE High Quality Standards

BLUE assures your sintered door lock parts quality with ISO 9001:2015 certified quality management system. We provide a one-year warranty on your sintered lock parts.

Standard Lock Fitting Shop

BLUE has a full range of standard powder metallurgy lock fittings in stock for fast delivery. Visit our standard parts shop to find the exact match for your applications.

Free Mold Design Service

With over 20 years of expertise in mold design, BLUE offers free, high-precision mold design services to meet your customized needs. Let our experience work for you!

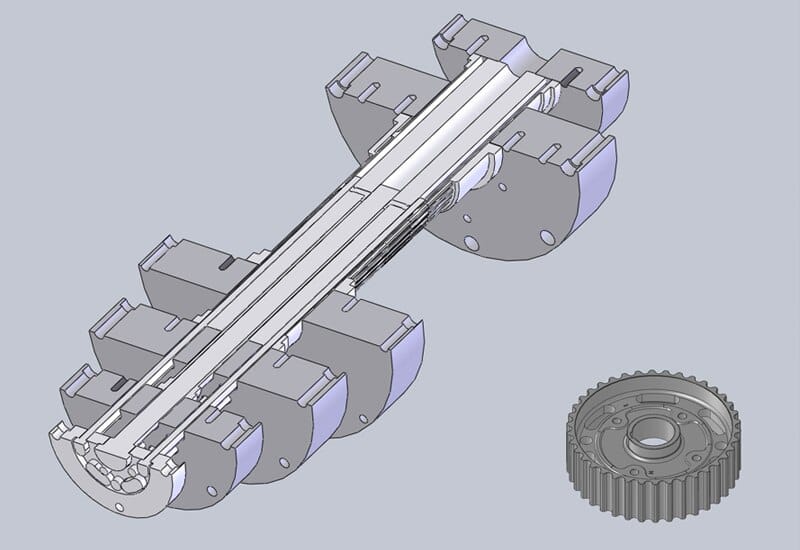

China Powder Metal Door Lock Parts

Our sintered lock fittings have good mechanical strength, wear resistance, corrosion resistance and long service life.

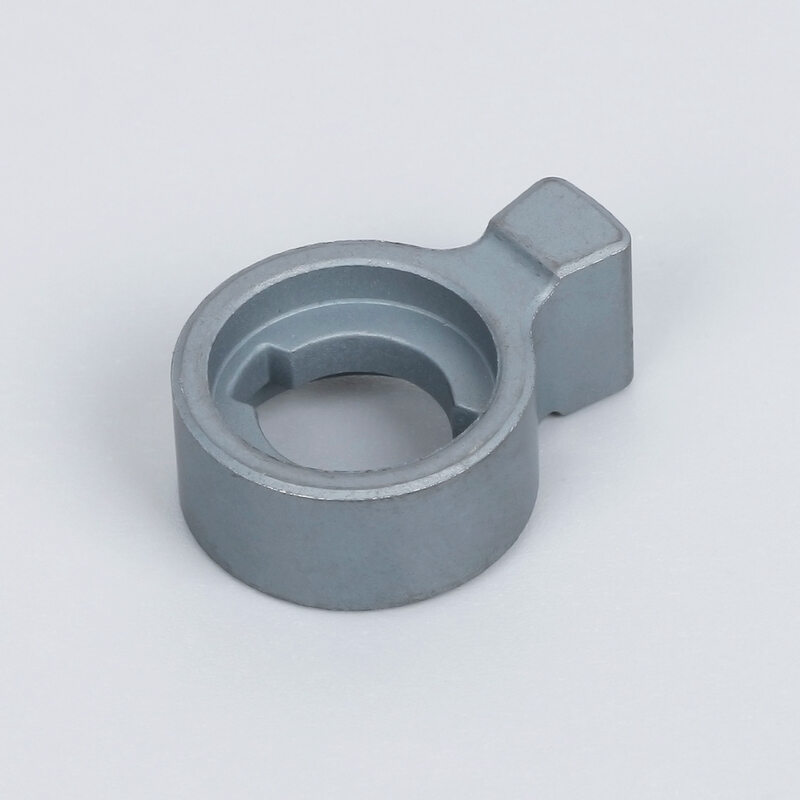

Lock Part

Our lock part has good surface finish, good corrosion resistance, and high dimensional accuracy.

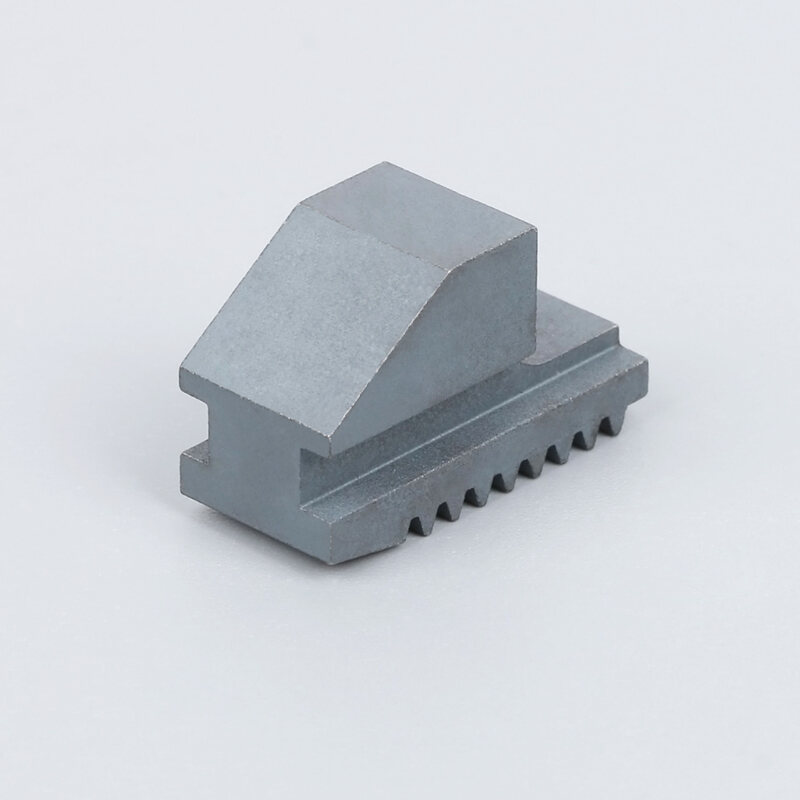

Sintering Metal Lock Fitting

Sintered metal lock fittings are made from metal powder through press-and-sinter processing, offering high material utilization.

Powder Metallurgy Lock Part

Our powder metallurgy lock parts feature tight tolerances, good mechanical strength and long service life.

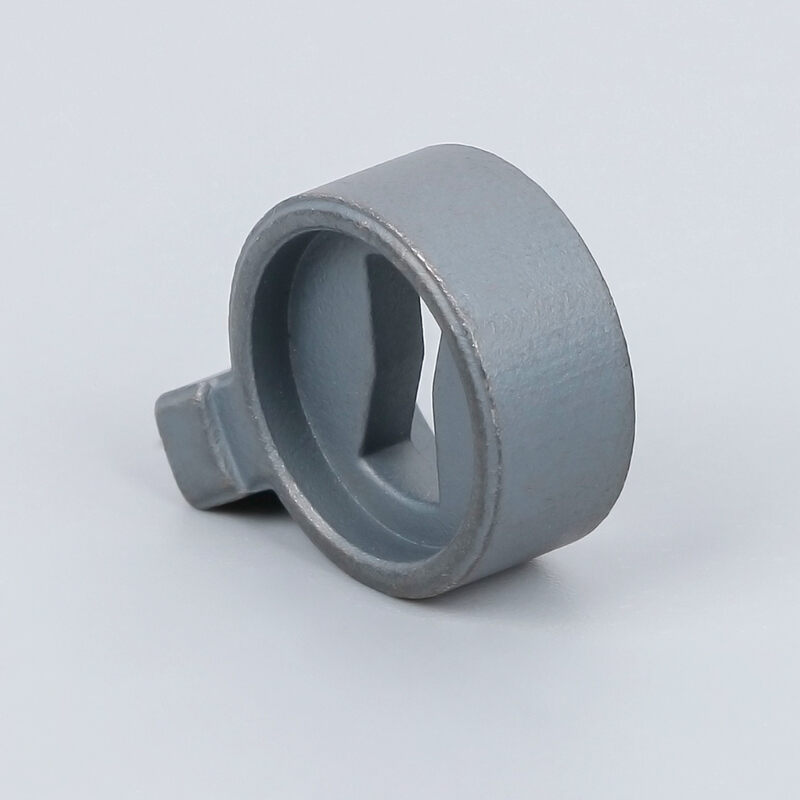

Powder Metal Lock Fitting

BLUE provides a variety of material options for your powder metal lock fitting, including FC-0205, FC-0208, FN-0205, FN-0208

Powdered Metallurgy Lock Part

Powder metallurgy lock parts Mass production has price advantages, and the materials are much cheaper than MIM.

Powdered Metal Lock Fitting

Our powdered metal lock fittings are made from high-quality raw materials, ensuring consistent quality and stable performance.

Sintered Lock Part

Our sintered lock parts are made from FC-0205 material. They feature uniform density and consistent strength.

Sintered Metal Lock Fitting

BLUE sintered metal lock fittings are steam-treated for a uniform appearance and enhanced corrosion resistance.

Sintering Lock Part

Our sintering lock part has the advantages of competitive price, fast production speed and stable quality.

What are Door Lock Parts?

Door lock parts are the components that allow a door to open, close, and lock securely. They work together to control movement of the latch or deadbolt and manage access to the room or building. Most mechanical door locks share a similar set of functional elements.

Key door lock parts include the lock body, which houses the internal mechanism, and the latch bolt, which keeps the door closed during normal use. Many locks also contain a deadbolt for higher security. The cylinder or keyway allows a key to operate the lock, while the strike plate on the door frame receives the latch or deadbolt.

Other supporting parts include the handle or knob, the spindle that connects both sides of the handle, and escutcheon plates that protect and cover the lock assembly.

How are Sintered Door Lock Parts Made?

Sintered door lock parts are produced using the powder metallurgy process. Metal powders are first mixed with lubricants to improve flow and compaction. The powders are then compacted in a precision die at 400–800 MPa to form the required shapes, such as cams, pawls and rotors. This compaction process creates a near-net-shape part with accurate geometry.

The compacted part, known as a green compact, is then sintered at a high temperature below the metal’s melting point. During sintering, the metal particles bond together and develop the strength, density, and dimensional stability needed for door lock applications. Many lock components benefit from this process because it delivers uniform mechanical properties and tight tolerances.

After sintering, the parts may go through several secondary operations. These include sizing to refine dimensions, CNC machining for critical surfaces, and heat-treatment processes to improve wear resistance. Steam treatment is often applied to enhance corrosion resistance and surface hardness. When required, the parts are plated or coated for additional durability.

BLUE Door Lock Parts Advantages

BLUE’s door lock parts feature high precision and a long service life.

We have a wide range of powder metallurgy Lock Parts, including lock cylinders, lock bolts, lock levers, and lock pins.

We can provide you with free samples, you can test them before placing an order.

We offer various surface treatment processes, including sandblasting, tumbling, plating, Dacromet coating, steam treatment, heat treatment, etc.

Standard Door Lock Parts

BLUE is committed to developing standard powder metallurgy parts that do not require tooling fees.

Our standard lock parts are basically in stock, so they can be shipped and delivered quickly.

These standard lock parts are available in a range of materials, including FC-0205, FC-0208, FN-0205, FN-0208, FX-1000, FX-1005, and FX-1008.

If you need custom lock accessories, we also provide tailored solutions to meet your requirements.

Advantages of Sintered Lock Parts

Sintered lock parts provide high material utilization with minimal waste and are cost-effective for mass production.

They offer consistent quality, with uniform density and reliable mechanical performance.

These sintered lock parts can be formed into complex shapes without the need for secondary machining.

Sintered components are able to meet tight tolerances, ensuring proper fit and function of precision lock assemblies.