Galvanized steel generally resists rust as long as its coating remains intact.

However, if the coating is damaged or exposed to harsh conditions for a long time, such as high temperatures, humidity, strong acids, or alkalis, rust may occur.

Contents

What is Galvanized Steel?

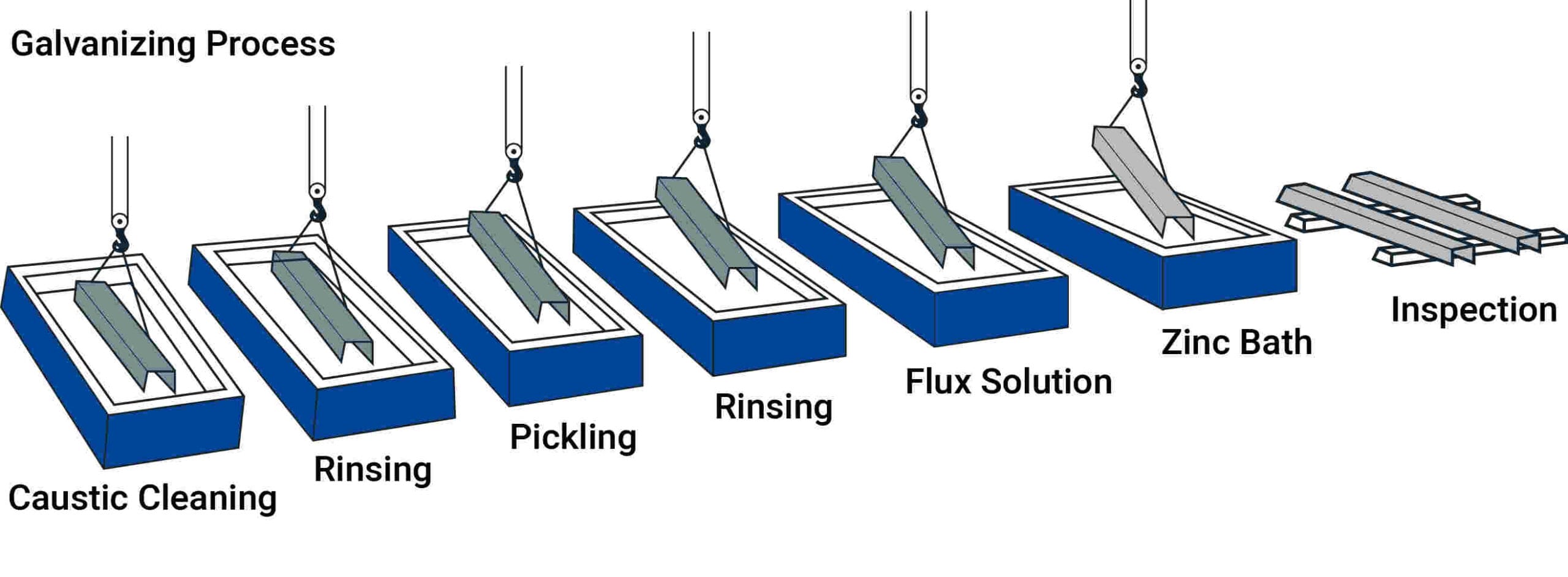

Galvanized steel is steel with a layer of zinc coating on the surface, which has excellent corrosion resistance. The galvanized layer can protect the steel material from moisture and environmental corrosion, and increase its service life. Common galvanizing methods include hot-dip galvanizing, galvannealing, pre-galvanizing and electro-galvanizing.

How does Galvanization Prevent Rusting?

Let’s first understand why iron or steel rusts.

Rust forms when the surface reacts with oxygen and water, creating iron oxide

Aluminum does not rust because it has a protective layer of aluminum oxide on its surface. Stainless steel does not rust because it contains chromium, which reacts with oxygen to form chromium oxide to protect it from air and other corrosion.

So in order to prevent steel from rusting, you should coat it with a protective layer. Galvanizing, the process of applying a zinc coating, is one of the most effective methods.

There are two reasons why galvanizing prevents steel from corroding:

- One is that galvanizing reacts more easily with oxygen and water vapor than steel, acting as a sacrificial anode for steel.

- Another reason is that galvanizing acts as a physical protective barrier for steel, preventing it from contacting oxygen or moisture.

Why does Galvanized Steel Rusts?

Although galvanized steel has good corrosion resistance, it can rust due to zinc coating damage and some environmental factors.

Zinc Coating

When the zinc coating is physically damaged, the steel is exposed to the environment and oxygen or water, which can cause rust.

High Humidity

In environments with humidity above 60%, the chance of galvanized steel rusting increases.

Pollutants

In cities, especially in industrial areas, sulfur dioxide gas reacts with zinc, causing the corrosion rate to double.

pH

Rust may occur when galvanized steel is exposed to harsh environments such as high humidity, high acidity or alkalinity, or contact with corrosive chemicals.

How to Maintain Galvanized Steel?

It is important to clean and maintain galvanized steel regularly to extend its lifespan.

Clean Regularly

Corrosive impurities and moisture on the surface of galvanized steel may accelerate its corrosion. So you’d better clean these contaminants on the surface of galvanized steel regularly to prevent it from corrosion.

Maintenance

When you find scratches or damage on the surface of galvanized steel, it is necessary to repair it in time. You can spray it with anti-rust paint. This is very helpful to prevent it from further corrosion and extend its service life.

Avoid Corrosive Environments

When galvanized steel is in high-humidity coastal areas or extreme pH environments or industrial parks, the corrosion rate will double. Avoid prolonged exposure to extreme environments or apply additional protection.

Protective Coating

You can add anti-rust oil, anti-rust paint, or epoxy coating to galvanized steel to further improve its corrosion resistance.

Salt Spray Test for Galvanized Steel

Salt spray test is a common method for checking the corrosion resistance of material surface coatings.

According to ASTM B117-19 standard, you immerse the galvanized steel sample in a 5% salt solution at a temperature of about 37°C and a pH between 6.5 and 7.2. Depending on the test requirements, the immersion time is 24 hours, 48 hours, or even 1000 hours.

After the test period, you inspect the sample for corrosion. If the sample remains corrosion-free, it passes the test.

FAQ

How Long does it Take for Galvanized Steel to Rust?

This depends on the use environment of the galvanized steel and the galvanized coating. In immersion environments and heavy industrial areas, galvanized steel will rust in a shorter time, perhaps less than 10 years. In the suburbs, where there is less pollution and a dry environment, galvanized steel can be used for decades or even longer.

Does Galvanized Steel Rust in Water?

Normally, galvanized steel with a complete zinc coating will not rust in fresh water. However, the conditions of the water environment such as oxygen content, pH, temperature, etc. will affect its corrosion rate.

Does Galvanized Steel Rust in the Ground?

Similar to water, the pH, moisture content, and chloride content in the soil affect the time it takes for galvanized steel to rust.

Will Galvanized Steel Rust in Saltwater?

Yes, galvanized steel will rust if exposed to salt water for long periods of time. Factors such as temperature, pH, oxygen, chlorides, etc. in the salt water will affect the corrosion rate.