Ceramic materials have high hardness, strong wear and corrosion resistance, excellent heat resistance, and good biocompatibility. However, due to their low toughness and brittleness, they are difficult to shape with traditional methods, and later machining is also challenging. Ceramic Injection molding is a new method that can directly obtain ceramic products with various complex shapes and high dimensional accuracy.

Contents

What Is Ceramic Injection Molding?

Ceramic Injection Molding is a manufacturing process where ceramics are created using the injection molding technique. It follows the same principle as plastic or metal injection molding by injecting fine ceramic powder and a thermoplastic binder into a mold to form particular 3D shapes. The formed shapes are later removed from the molds and passed through a sintering process at high temperature to achieve a final result.

CIM dates back to the 1920s when it was first used to fabricate spark plug bodies. 60 years later it was used to shape components of ceramic heat engines in Japan and Europe. Now, CIM is a go-to method for manufacturing components used across several industries including the medical, electrical, and high-precision field applications. Due to the increasing demand, the CIM market is projected to grow from USD 349.84 million in 2012, to USD 603.17 million in 2028, recording a CAGR of 8.3%.

Ceramic Injection Molding Process

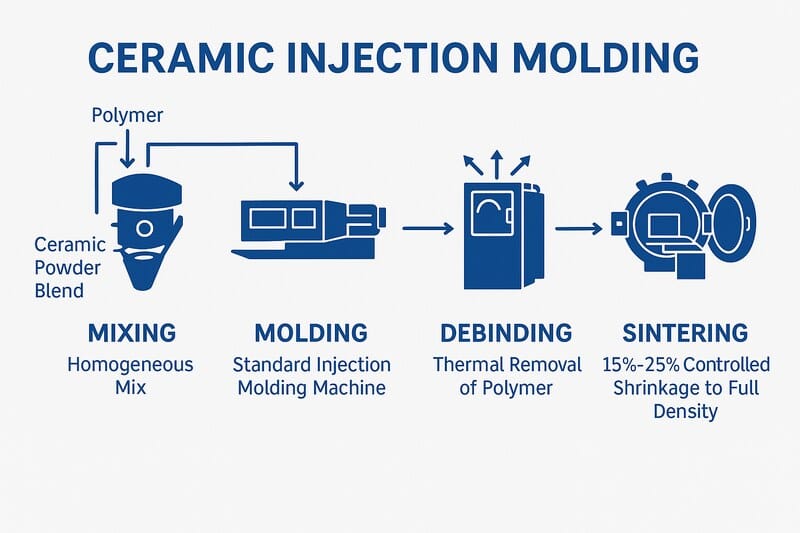

The CIM process is a combination of two already established and popularly used technologies: Powder Metallurgy and Injection Molding. This combination is what gives birth to complex shaped ceramics as the end product of CIM. The process is completed in four main steps:

Feedstock Preparation

The feed material is a uniform mixture of ceramic powder and binder. The ideal feed material should have good uniformity and fluidity.

Injection Molding

In the injection molding process, the feedstock is first heated and melted in the injection unit of the molding machine. The screw then moves forward to inject a controlled amount of molten feedstock into the mold. As the mold is cooler than the feedstock, heat is transferred to the mold, causing the material gradually solidify. Once it reaches sufficient hardness, the mold opens and the ceramic injection molded part is removed.

Debinding

In this next step, the binder is removed to form a Brown Part, and this is done through either of these two processes:

A chemical treatment that dissolves the waxes or other soluble binders, known as solvent debinding.

A heat treatment that gradually burns off remaining binders under controlled conditions, known as thermal debinding.

4. Sintering

Finally, the Brown Part is passed through the sintering process under specific temperature and atmospheric conditions until the desired density is achieved. Then the sintered product is allowed to shrink to about 15 – 20%, and its mechanical and thermal properties are established.

Ceramic Injection Molding Materials

For the CIM process to be successful, you’ll need to work with a combination of ceramic powders and binders.

Common Ceramic Powders Used in CIM

Alumina (Al₂O₃)

Alumina is a commonly used material for CIM, with good hardness, wear resistance, and corrosion resistance.

Zirconia (ZrO₂)

It is known for its excellent mechanical properties, high strength, toughness, and resistance to wear and corrosion.

Silicon Nitride (Si₃N₄)

Silicon Nitride is chosen for its excellent thermal shock resistance and high-temperature strength.

Silicon Carbide

Silicon Carbide (SiC) is known for its exceptional hardness, thermal conductivity, and resistance to chemicals.

Common Binders Used in CIM

Adhesives can be mainly divided into thermoplastic system, thermosetting system, gel system and water-soluble system according to the adhesive components and properties. The following is a detailed comparison of them.

| Binder System | Main Components | Advantages | Disadvantages |

|---|---|---|---|

| Thermoplastic System | Paraffin wax, polyethylene, polypropylene | Good compatibility and flowability, easy to mold, high powder loading | Long debinding time, complex process |

| Thermosetting System | Epoxy resin, phenolic resin | High green strength, fast debinding | Injection process is hard to control, poor compatibility, many defects |

| Gel System | Methyl cellulose, water, glycerol, citric acid | Low organic content, fast debinding | Low green strength, difficult debinding |

| Water-soluble System | Water-soluble cellulose, gelatin | Fast debinding speed | Low powder loading |

Advantages of Ceramic Injection Molding

- Contrary to traditional methods, it is very useful in creating complex geometries with net or near-net shapes.

- Ensures high precision due to its tight tolerances.

- It has a very smooth surface finish that is free of defects.

- Allows for excess feedstock to be recycled, making it very cost-effective as material waste is minimized.

- It is suitable for high-volume production

Challenges and Limitations

- High cost of equipment and tools needed for the process..

- The process needs highly skilled operators for it to be successful.

- It is limited to small-sized components because larger components are prone to stress during debinding.

Comparison Between CIM and Slip Casting

Below is a detailed comparison between ceramic injection molding and slip casting.

| Feature / Factor | Ceramic Injection Molding (CIM) | Slip Casting |

|---|---|---|

| Complex Geometry | Excellent for producing intricate, complex shapes with tight tolerances | Limited; suitable for hollow or simple shapes |

| Production Volume | Ideal for high-volume production once tooling is made | Best for low-volume or custom pieces |

| Tooling Cost | High initial cost due to mold design | Low tooling cost; simple molds |

| Dimensional Accuracy | Moderate | Low to moderate; may require trimming and machining |

| Surface Finish | Smooth, high-quality surface finish | Rougher surfaces; often need glazing or polishing |

| Material Waste | Minimal; high material utilization | Higher waste due to casting residues and mold overflows |

| Cycle Time | Fast once set up; highly repeatable | Slow drying and casting can take hours |

| Debinding and Sintering Sensitivity | Requires controlled debinding and sintering steps | Generally more forgiving, but slow drying is critical |

| Scalability for Large Parts | Limited; better for small to medium parts | Flexible for producing large or bulky components |

| Initial Setup Time | Long (due to feedstock formulation and mold making) | Relatively short; simple equipment needed |

Ceramic Injection Molding Applications

Ceramic injection molded parts feature excellent corrosion resistance and biocompatibility, with broad applications, particularly in the medical field.

Medical and Dental

- Orthopedic implants (e.g., hip and knee prostheses)

- Dental crowns, brackets, and implants

- Surgical tools with biocompatibility and wear resistance

Electronics

- Ceramic insulators and housings

- Substrates for circuit boards

- Connectors and sensor casings

Automotive and Aerospace

- Turbocharger rotors and fuel injector components

- High-temperature, wear-resistant parts for engines and turbines

Industrial and Consumer Products

- Cutting tools and wear parts

- Watch components and ceramic bezels

- Seals, valves, and pump components used in corrosive environments.

Looking for ceramic injection molding companies? BLUE is your trusted partner with 10 years of experience and ISO 9001:2015 certification. We provide CIM services for small, complex parts using a range of materials including alumina, zirconia, silicon nitride, and silicon carbide.

FAQ

1. What Is the Ideal Sintering Temperature Range For A Ceramic Injection Molding Process?

Though it depends on the type of ceramic material used, the general sintering temperature range needed for a CIM process is within 1200 to 1600 oC.

2. What Effect Does A Poorly Done Debinding Process Have on the CIM Procedure?

Improper debinding during the binder removal process can lead to cracks and other defects, like blistering and warping. This results in a very poor densification during the sintering process, hence, a bad end product.