What is Pressureless Sintering

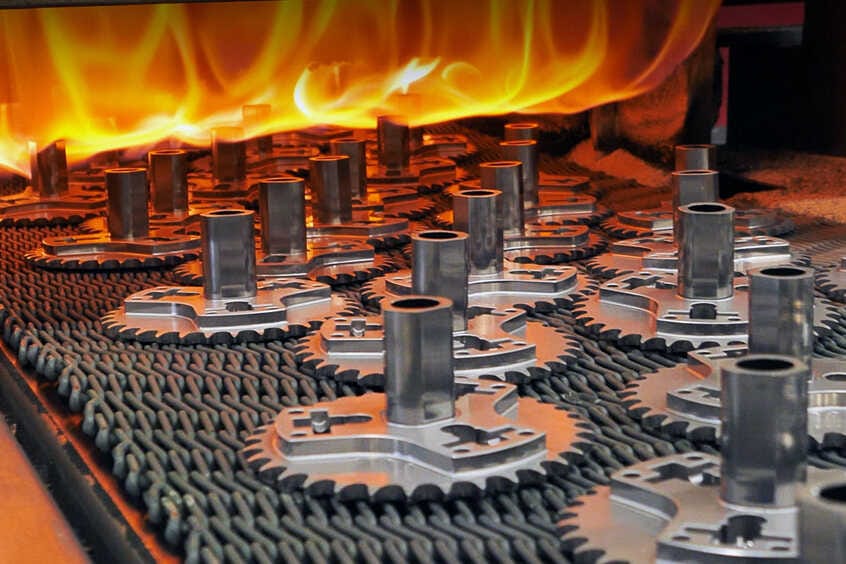

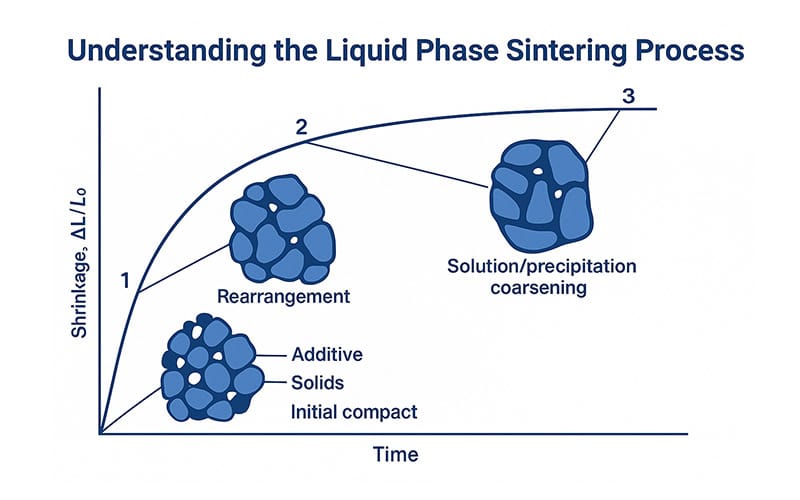

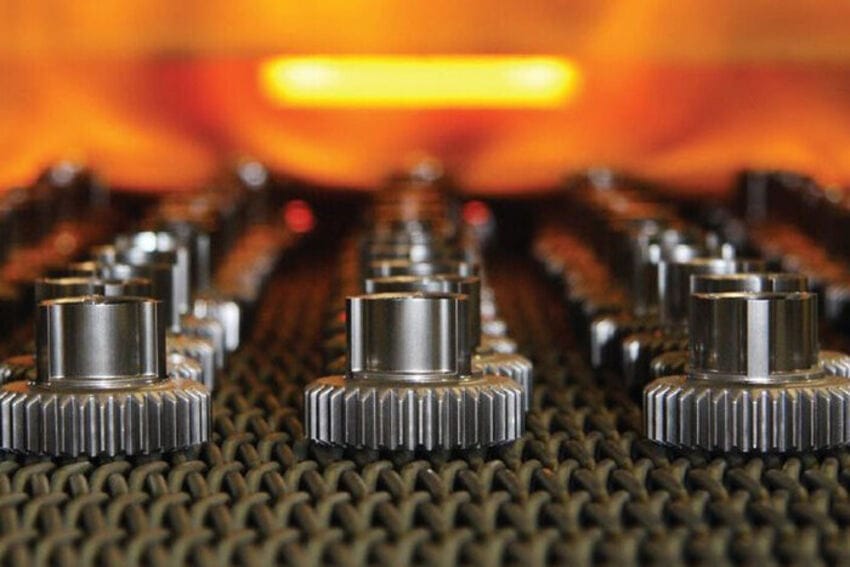

Pressureless sintering is a sintering process in which powder material is converted into dense components without applying external pressure during sintering. The process depends solely on controlled heating to promote atomic diffusion and bonding between particles. It is used for producing components where uniform microstructure,