Metal Injection Molding vs Metal 3D Printing

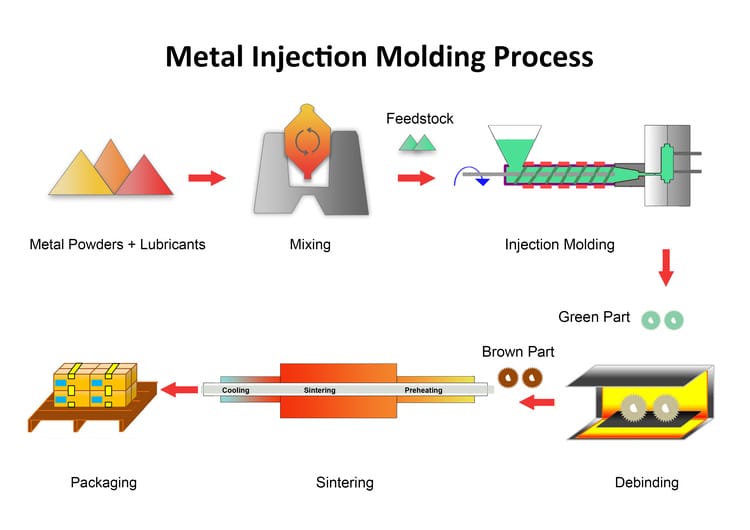

Metal injection molding (MIM) and metal 3D printing are advanced production technologies that have brought about a rapid shift in modern manufacturing. Metal injection molding can create small and intricate components as tiny as 2 mm in diameter, while weighing less than 1 g without