BLUE High Quality Standards

BLUE is a top-quality supplier of powder metal parts in China, each of your parts has gone through a strict quality control process based on internal and ISO9001: 2015 standards.

How does BLUE Control Your Parts?

Quality control is our top priority, ensuring perfection in every part from the initial design to the final product, so you can trust in the consistency and reliability of our services.

Certificates & Standards

- ISO 9001 : 2015

- IATF 16949 : 2016

- DIN ISO 2768

- DIN 30910

- MPIF Standard 35

Quality Control

- Development Review

- Sample Inspection

- Process Inspection

- Appearance Inspection

- Final Inspection

- Raw Material Certificate

Packaging & Shipping

- Plastic Blister

- Multi-layer Carton

- Fumigation-free Pallet

- Fumigation-free Wooden Case

- UPS, TNT, FedEx and EMS

- Air and Ocean Shipping

Quality Standards

BLUE is ISO 9001-2015 and IATF 16949:2016 certified, guaranteeing top-quality powder metallurgy parts.

- ISO9001: 2015 is for the production and processing control of all powder metallurgy parts, ensuring bath to batch consistency.

- IATF 16949:2016 is a standard for the automotive industry. We can provide PPAP leverl 3 control process to ensure that the product meets the standard.

- MPIF standard 35 raw materials are consistent with international standards. BLUE purchases some raw materials from the TOP 3 powder suppliers in Europe and the United States to ensure the same quality as your local.

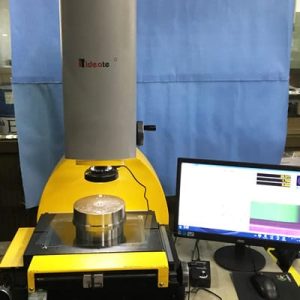

Dimension Inspection

Our standard inspection process covers product development reviews, first piece inspection, in-process inspection, sampling inspection, and final inspection.

To ensure data accuracy, our advanced inspection equipment includes coordinate measuring machines (CMM), profilometers, projectors, micrometers, vernier calipers, height gauges, and more.

BLUE provides full inspection reports and material reports for every order before shipment.

Appearance Inspection

Some powder metallurgy parts are used for decorative purposes, making their appearance especially important.

We maintain strict quality control standards for the appearance of sintered parts:

- Compacting process: BLUE inspect for burrs, powder loss, cracks, uneven density, and surface dents.

- Sintering process: We check for color consistency, cracks, dust, and bubbling.

- Sizing process: We eliminate any products with scratches, cracks, dents, or being dropped.

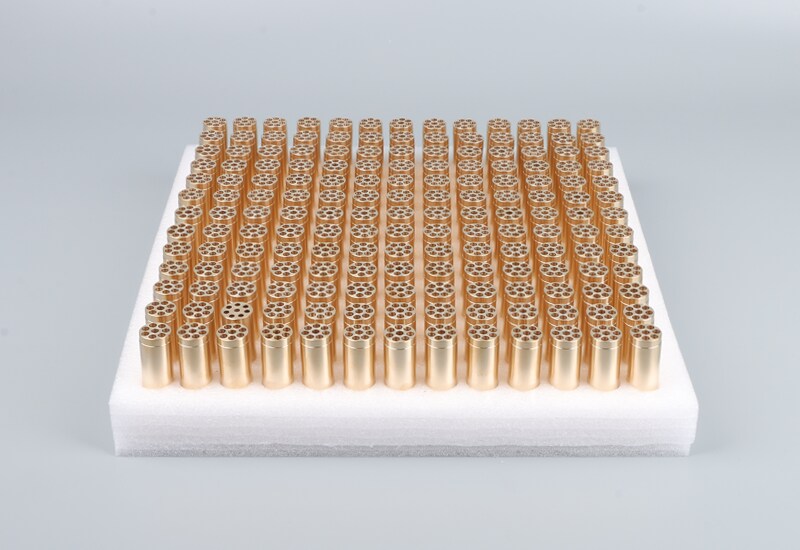

Safe Packaging

BLUE provides secure and reliable product packaging to ensure your products are safe throughout every stage of transportation.

- First, all products undergo ultrasonic cleaning, leaving them spotless, and are treated with an oil coating for rust protection lasting up to 6 months or more.

- Each part is carefully packed in eco-friendly blister trays to prevent collisions and damage during transport.

- These parts are then placed in sturdy carton boxes made from four-layer or higher corrugated cardboard.

- Finally, all cartons are packed into fumigation-free wooden crates, ensuring that the products you receive are as fresh as when they were first produced.

BLUE Main Inspecting Equipments and Tools

BLUE has a wide range of advanced testing equipment and tools, including coordinate measuring machines, profilometers, projectors, height gauges, and micrometers, to provide comprehensive inspection reports.

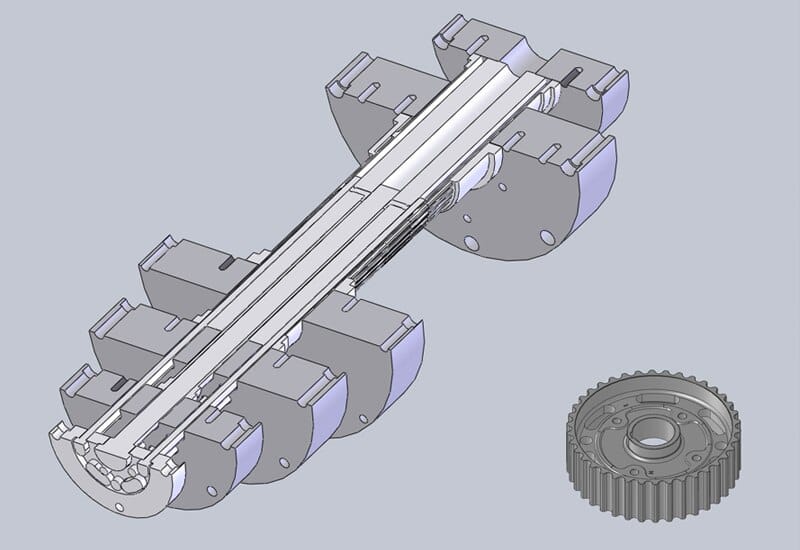

Learn More About BLUE's Advantages

BLUE offers a full range of powder metallurgy standard parts to customers worldwide, along with online ordering, free design, and mold manufacturing services. All sintered parts pass stringent inspections to ensure high and consistent quality.

Free PM Mold Design

With 20+ years of experience, we return 2D design drawings and provide comprehensive mold machining services.

Standard Parts Shop

No mold fees for all standard powder metal parts, easy to online selection, and free samples prior to ordering.

Download Product List

Download full product list for free, stay updated with new releases and the flexibility to accept customized orders.