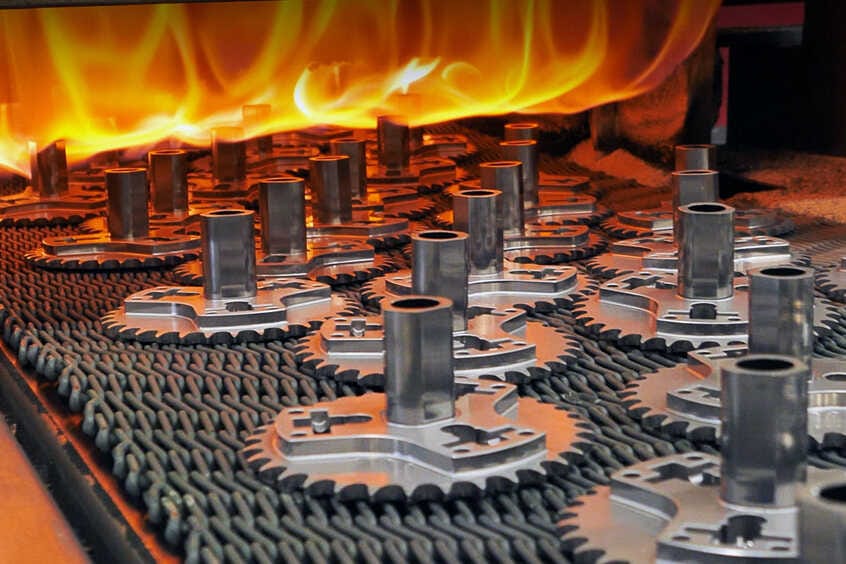

Solid State Sintering

Solid state sintering is a heat treatment process in which loose powder is converted into solid coherent components. The process is conducted at elevated temperatures, typically between 70% and 90% of the material’s melting point. This heating leads to the formation of chemical bonds between