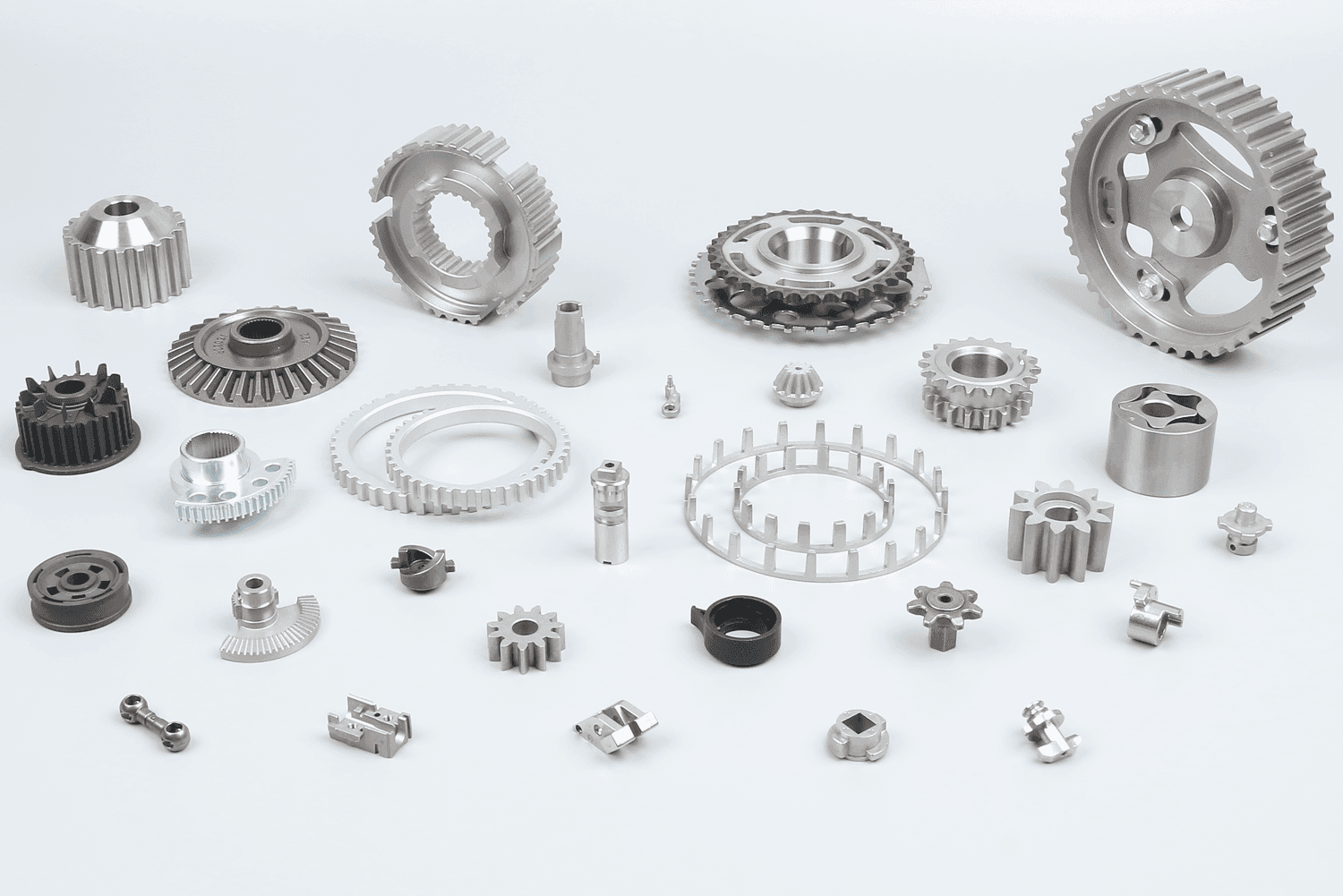

How Powder Metal Parts Are Used in Office Equipment

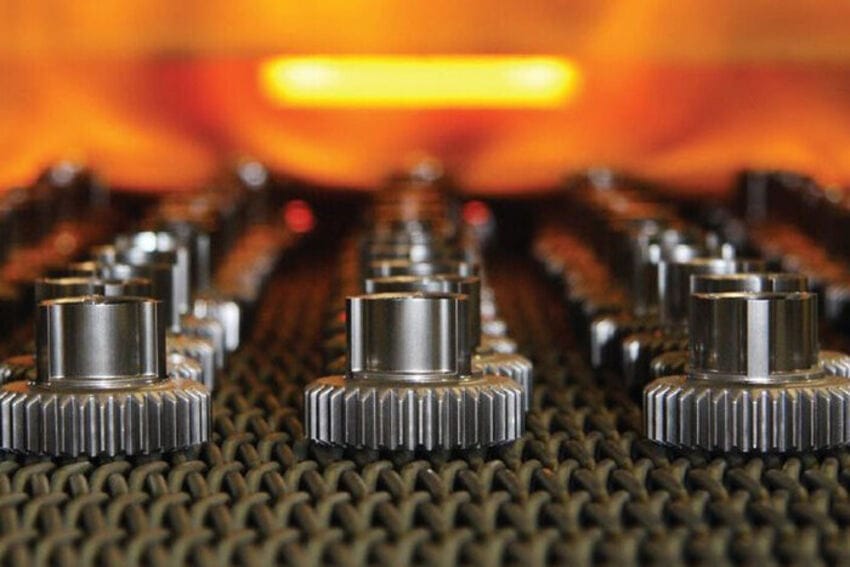

Powder metallurgy is a manufacturing process in which metal powders are compacted into specific shapes and then sintered at high temperatures below the metal’s melting point to form solid components. This approach allows complex geometries to be produced with minimal material waste and consistent dimensional