Powder metallurgy (PM) has gained importance in lock parts manufacturing because it offers both precision and durability to the components. Lock components was manufactured using casting and machining, which are material-intensive and less efficient for complex geometries. In contrast, PM enables cost-effective mass production of components such as latches, and cylinder housings with consistent quality.

Contents

Powder Metallurgy process for Lock Parts

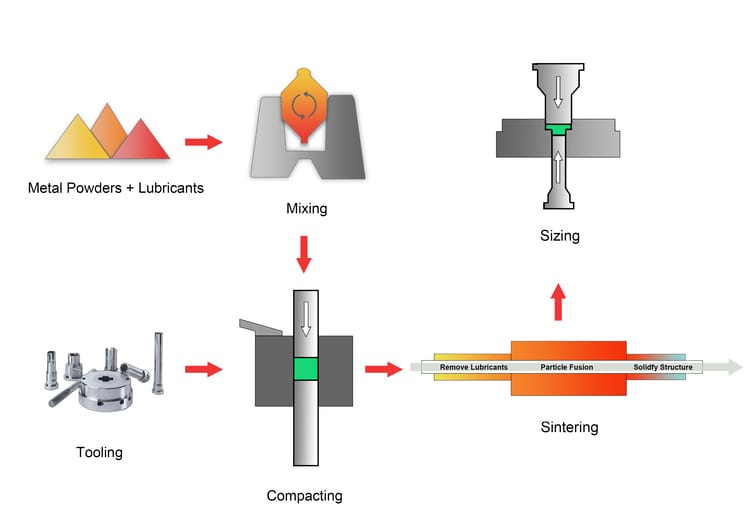

The following outlines the key steps in the typical powder metallurgy process for manufacturing lock parts.

Mixing

Iron-based or stainless powders are blended with 0.5–0.8% lubricant. Flow rate and apparent density are checked to keep batch consistency.

Compaction

Rigid steel tooling with multi-level punches forms the green compacts at 500–800 MPa. Critical holes and grooves follow the pressing direction; optional warm compaction at 120–150 °C raises green density.

Sintering

Compacts are sintered at 1120–1150 °C in N₂–H₂ or controlled atmospheres. Particle neck growth and densification deliver stable microstructure and predictable shrinkage.

Sizing

Sizing refines sintered lock parts to IT6–IT8 tolerances and improves flatness, roundness, and coaxiality.

Steam treatment

In steam treatment, lock parts are exposed to 550–570 °C water vapor to form a dense Fe₃O₄ layer, improving wear resistance, corrosion resistance, and micro-sealing at contact surfaces.

Subsequent machining and deburring can be performed as required.

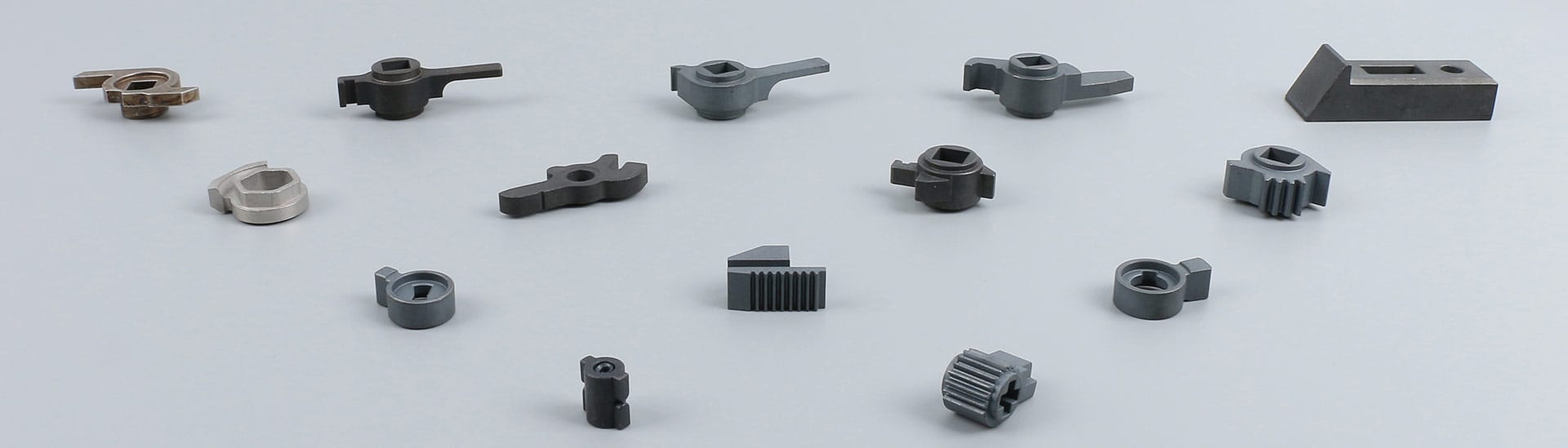

Where Powder Metallurgy Is Used in Lock Systems?

Powder metallurgy is used across residential and commercial door locks, fire-rated systems, electronic and smart locks, cabinet locks, UPVC door locks, and mortise mechanisms.

Specific PM lock components include latch bolts and deadbolts, cylinder housings, cams, pawls, forks, shafts, sleeves, plates, levers, clips, and positioning blocks.

Latch Bolt Components

The latch’s bolt components such as latch bolt, deadbolt, magnetic latch, and safety bolt, serve as the first line of defense in the lock system. That is why they must withstand constant sliding and impact in repetitive cycles of locking and unlocking. For this purpose these components require high strength and dimensional consistency which are introduced in them by powder metallurgy. PM offers uniform density to these parts, ensuring smoother operation and extended service life.

Lock Cylinder Components

Manufacturers use PM to produce near-net-shape lock cylinder components with tight dimensional tolerances. This minimizes the need for secondary machining which ensures wear resistance and long-term reliability.

Transmission Parts

Inside many locks, a hidden system of pawls, forks, cams, and shafts transfers motion from the key or actuator to the bolt. These components carry the mechanical load that’s why poor quality of these components can lead to jams or breakage. Manufacturers can create transmission parts with high mechanical strength to ensure efficient transmission of force from the key through sintering.

Auxiliary Parts

Many lock components go unnoticed such as sleeves, plates, levers, clips, and positioning blocks but are essential for keeping the mechanism intact. Their role is to maintain stability, alignment within a lock system. Powder metallurgy helps by delivering consistently reliable pieces that keep the overall assembly durable while trimming production expenses.

Materials Used in Powder Metallurgy Lock Parts

Stainless Steel Grades

Stainless steels are widely used in lock components where corrosion resistance, strength, and wear performance are essential.

Here are the common grades of stainless steel:

- Stainless Steel 300-series: These include 304, 316, which are effective for corrosion resistance in outdoor or humid environments

- Stainless Steel 400-series: Including 410, 420, known for higher hardness and wear resistance in moving lock parts.

Iron-Based Alloys

Iron-based alloys are the most common materials used to manufacture sintered lock parts due to their low cost, machinability, and good mechanical strength. Iron is alloyed with carbon, copper, or nickel to enhance its toughness, wear resistance, or dimensional stability.

Benefits of Powder Metallurgy in Lock Components

Dimensional Accuracy and Complex Geometries

The dimensional precision is crucial in locks because even minor deviations can affect alignment and security performance. In PM, metal powders are compacted in rigid dies and then sintered with predictable shrinkage. That’s why components produced are already close to their final shape. However if tighter tolerances are required, secondary steps like sizing or machining are done to fine-tune the dimensions.

Strength and Wear Resistance

During sintering, metal particles fuse to create strong metallurgical necks and gradually densify. This process increases the load-bearing surface and reduces porosity and microstructural discontinuities that typically cause wear. With proper density and heat treatment, PM steels deliver durable bolts, and tumblers that survive high cycle counts. This ensures long service life in parts subjected to continuous mechanical interaction.

Corrosion Resistance

By using stainless steels and surface treatments, like steam treatment, PM parts gain resistance to moisture and harsh environments. This protection helps prevent rust and material degradation in outdoor or high-humidity lock applications.

Cost Reduction and Resource Efficiency

In traditional machining, much of the raw metal ends up as scrap. Whereas in PM, nearly all the starting powder becomes part of the final product. Material savings, combined with lower energy demand during processing, make it a cost-effective choice.

Scalability for Large-Volume Production

The repeatability of PM makes it ideal for mass production of uniform parts. This enables lock manufacturers to meet global demand while maintaining consistent quality.