Angle Grinder Gear | BLUE

BLUE angle grinder gears have high tooth profile accuracy, high surface hardness, good wear resistance, and good core toughness. We offer standard sintered gears compatible with most angle grinder models—contact us to get free samples!

Why Choose BLUE?

BLUE is your reliable supplier, offering high-quality angle grinder gears with precise tooth profiles, high strength, durability, and free mold design services.

BLUE High Quality Standards

BLUE guarantee the quality of your angel grinder gears with an IATF 16949: 2016 certified quality management system. Free samples are available for testing.

Standard PM Parts Shop

BLUE has a full range of standard engine valve guide in stock for fast delivery. Visit our standard parts shop to find the exact match for your applications.

Free Mold Design Service

With over 20 years of expertise, BLUE provides free, high-precision mold design services tailored to your needs. Trust our experience to deliver for you!

BLUE Angle Grinder Gear in China

BLUE offers a variety of angle grinder gears—find exactly what you need for your applications or request a custom solution.

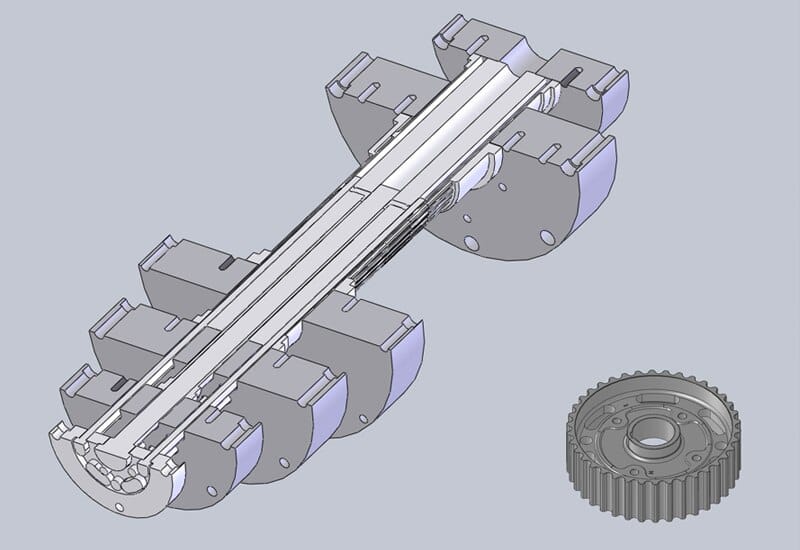

Angle Grinder Bevel Gear

BLUE angle grinder gears offer high tooth profile accuracy, good surface hardness, and excellent wear resistance

Angle Grinder Gear Set

BLUE angle grinder gears have a precise tooth profile, which enables smooth power transmission and minimizes noise and vibration during operation.

Sintered Angle Grinder Gear

Sintered angel grinder gear uses iron-based metal powder as raw material, such as FC-0205, FD-0205, and the material utilization rate is as high as over 95%.

What is a Angle Grinder Gear?

An angle grinder gear is a precision-machined bevel gear set that powers the spindle 90° to the armature of the motor. This drive means is capable of efficiently transferring power and for keeping thereat the high rotating speed necessary in case of cutting, grinding and polishing work.

Made from carburizing alloy steel or sintered steel, and finished-face with precision, the spiral bevel gear features high-strength, compact composition and reliable performance.

The accuracy and wear performance of angle grinder gear affect the angular grinders’ torque oiliness, vibration stability, as well as working life.

Powder Metal Manufacturing Process of Angle Grinder Gears

The bevel gears of an angle grinder are usually manufactured by the powder metallurgyprocess in which the metal powders such as Fe-Cu-C or alloy steel are compressed and processed into accurate tooth shapes in a sintering process.

The parts are sintered at about 1120–1150 °C in a controlled atmosphere after pressing under high pressure to produce strong metallurgical bonds. Post-treatments such as sizing, sinter-hardening and oil-impregnation also contribute to the accuracy, hardness and lubrication.

Such PM process offers high productivity and uniform quality and provides wear resistance, making it suitable for high-speed power tools.

BLUE Angle Grinder Gear Advantages

BLUE angel grinder gears are produced under the strict control of IATF 16949:2016.

Our powder metallurgy gears have high strength to withstand high torque and resist wear.

After heat treatment, the apparent hardness of our gears exceeds 40 HRC, with a core hardness of HV₀.₀₅ 400.

BLUE copper-infiltrated angle grinder gears feature a density of 7.4 g/cm³ and an apparent hardness of HRA90.

Heat Treatment of Sintered Gears

Quenching and Tempering

This process enhances the gear’s wear resistance and increases core strength.

Carburizing

Carburizing is a common heat treatment method for angle grinder gears. The material’s porosity significantly affects the depth of the hardened layer. Typically, the density of sintered gears should exceed 7.0 g/cm³.

Induction Quenching

Induction quenching creates a hard, wear-resistant surface on the angle grinder gear while preserving its internal toughness.

Adavantages of Sintered Angle Grinder Gear

Compared with the material utilization rate of cutting processing, which is only 54%, the material utilization rate of powder metallurgy gears is over 95%.

Compared with forged gears, sintered gears have fewer processes and less energy consumption.

Since sintered gears are die-formed, the shape and precision of the teeth are consistent.

Powder metallurgy can easily produce the ideal asymptotic tooth profile and full root fillet radius of gears.

Testing of Angle Grinder Gear

BLUE provides comprehensive testing services for powder metallurgy gears.

- Density: Tested according to GB/T 5163 using a densitometer.

- Dimensional Accuracy: Outer diameter and height measured with a micrometer.

- Gear Tooth Accuracy: Measured with a Gleason 300GMS.

- Surface Hardness: Tested using an HRB/HRC hardness tester.

- Effective Hardened Layer: Evaluated per GB/T 9540 with a microhardness tester.

- Tooth Resistance: Measured with a materials testing machine.

- Torsion Strength: Evaluated with a torsion testing instrument.

Custom Angle Grinder Gear Specifications

The table shows our manufacturing capabilities for customized angel grinder gears, including material, density, hardness, and bore tolerance.

| Attribute | Value |

|---|---|

| Material | FC-0205, FC-0208, FN-0205, FD-0205, FX-0208, SMF4040, D39 |

| Density | 6.8-7.0g/cm3 |

| Hardened Hardness | Min. 40 HRC |

| Bore Tolerance | ±0.01 mm |

| Accuracy of Gears | DIN/ISO 8 |