About Us

A New Way to Purchase Powder Metal Parts!

Why BLUE Powder Metallurgy?

Founded in 2010, BLUE Powder Metallurgy brings together an experienced engineering team dedicated to advancing powder metallurgy technology.

Our expertise covers the full range of PM processes from powder selection and compaction design to sintering and post-treatment allowing us to support customers with reliable, high-performance components across automotive, power tools, and industrial applications.

With strong technical background and a strict quality control system certified to ISO 9001:2015 and IATF 16949:2016, we ensure every part meets global standards for precision and durability.

BLUE continues to focus on product innovation, process optimization, and global supply consistency making powder metallurgy solutions more efficient, accessible, and cost-effective for manufacturers worldwide.

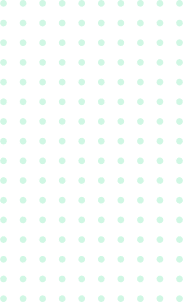

BLUE Powder Metallurgy Factory Equipment

BLUE has a complete range of advanced powder metallurgy production equipment, including 25T to 1000T compaction press, conveyor belt sintering furnace, vacuum sintering furnace, sizing press, CNC machining equipment, machine center, hardening furnace, etc.

BLUE Fully Automatic Powder Metallurgy Production Line

Our highly automated powder metallurgy production line combines efficiency with cost-effectiveness, guaranteeing uniform quality across all batches. Watch the video below to see our automated PM production line in action.

#1 Powder Metallurgy Standard Parts

BLUE’s online shop features a full range of precision powder metallurgy standard parts, developed through years of process refinement and engineering experience.

All parts are produced with existing molds, helping to reduce cost and accelerate the ordering process.

Free samples are available for evaluation, and most items are ready for immediate delivery from stock.

#2 Download Full Range Product List

Access the complete range of powder metallurgy products, including detailed specifications on materials, dimensions, and models for easy selection.

Our product library covers a wide variety of standard sintered components—such as oil pump rotors, timing gears, and filters engineered through years of process refinement and application experience.

Free samples are available for testing before purchase, and most items are available for immediate dispatch.

#3 BLUE High Quality Standards

BLUE operates under ISO 9001:2015 and IATF 16949:2016 certified quality systems, ensuring every powder metallurgy part is produced with precise process control and traceable consistency.

Our quality management covers the entire production chain from raw powder inspection and compaction density verification to sintering atmosphere control and final dimensional testing.

Each batch is validated to PPAP Level 3 standards, meeting the requirements of the global automotive industry.

All materials conform to MPIF Standard 35, ensuring consistent mechanical performance and long-term reliability.

#4 Free Mold Design Services

BLUE offers professional mold design support backed by over 20 years of engineering experience in powder metallurgy.

Our technical team develops precision tooling for complex components such as oil pump gears and water pump pulleys, optimizing density distribution and dimensional accuracy from the initial stage..

We design both compacting and sizing molds with precision tolerances of ±2 µm and surface finishes of Ra 0.2–0.4 µm, ensuring stable quality and extended tool life in serial production.

Through integrated design and manufacturing control, BLUE helps customers achieve faster product validation, reduced tooling cost, and consistent performance in mass production.

#5 BLUE OEM & ODM Capabilities

BLUE supports OEM and ODM projects with complete powder metallurgy engineering capabilities, covering product design, tooling development, prototyping, and mass production support.

Our engineering team collaborates closely with production facilities under a unified quality management framework, ensuring traceable processes, dimensional accuracy, and cost efficiency.

Each project undergoes PPAP documentation and performance validation before delivery.

By integrating design optimization, material testing, and production validation, BLUE delivers reliable powder metallurgy solutions that meet the technical and performance requirements of global manufacturers.

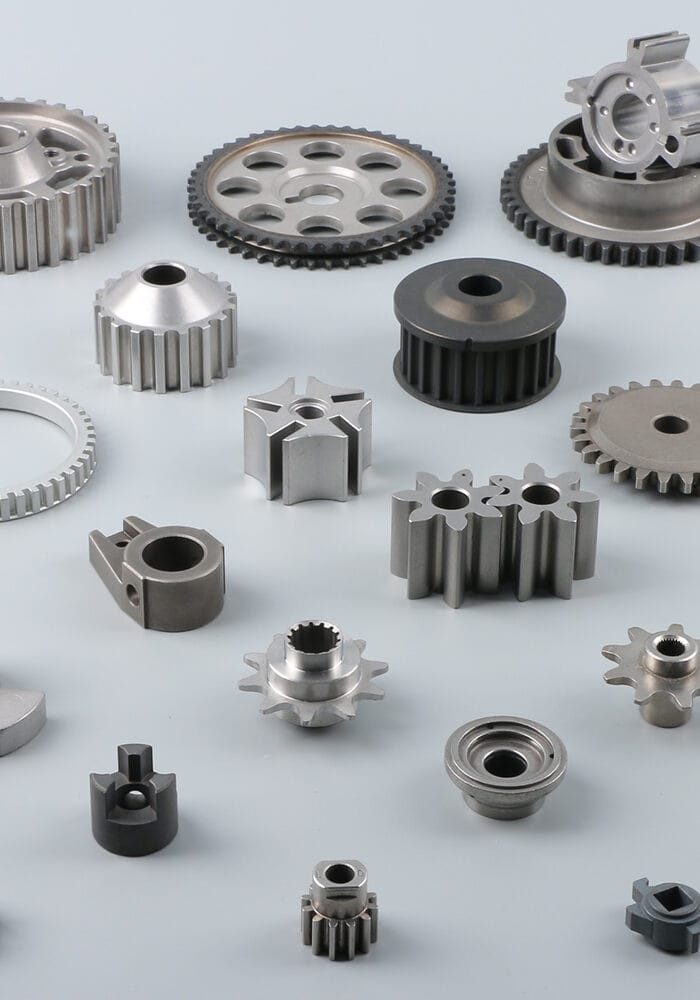

BLUE Powder Metallurgy Parts Capabilities

We provide an integrated solution for powder metallurgy components, covering PM parts, MIM parts, sintered filters, and advanced sintered ceramics, all developed under strict quality control and engineered for reliable performance.

PM Parts

High-precision powder metallurgy parts manufactured for strength, dimensional stability, and cost efficiency. Available for gears, bushings, pulleys, and other structural applications requiring consistent performance.

MIM Parts

Metal Injection Molding (MIM) components with complex geometry, high density, and superior surface finish. Designed for applications where precision and miniaturization are critical.

Sintered Filters

Porous metal filters engineered for corrosion resistance and stable flow control. Ideal for use in hydraulic systems, loudspeaker, medical treatment, and chemical processing environments.

Sintered Ceramics

High-performance ceramic components offering outstanding hardness, wear resistance, and thermal stability. Suitable for demanding conditions involving high temperatures or aggressive media.