Iron-based compressor valve plates are core functional components in reciprocating refrigeration and air-conditioning compressors. Their geometry, flatness, and mechanical stability directly influence sealing efficiency, volumetric performance, and long-term reliability. As compressor designs move toward higher efficiency and tighter tolerances, conventional manufacturing routes increasingly struggle to balance precision, cost, and scalability. Net-shape manufacturing technologies, especially powder metallurgy, are becoming a preferred solution for modern iron-based compressor valve plates.

This article discusses the function and performance requirements of compressor valve plates. It also reviews the limitations of traditional manufacturing methods and explains how net-shape powder metallurgy addresses these challenges.

Contents

Function of Iron Based Compressor Valve Plates

In reciprocating compressors, valve plate acts as the interface between the cylinder and the suction and discharge valve assemblies. It separates flow paths while providing a stable sealing surface under cyclic pressure and temperature variations.

In typical household refrigeration compressors, the valve plate is a thin, flat component, with overall dimensions commonly in the range of 45–65 mm × 35–55 mm, and a thickness of approximately 3.0–3.5 mm. Despite its relatively small size, it must withstand repeated valve reed impacts, gas pressure fluctuations, and thermal cycling throughout its service life.

Because the compressor valve plate directly affects gas sealing and valve timing, even minor geometric deviations can lead to leakage, reduced volumetric efficiency, increased operating temperature, and accelerated valve wear. For this reason, iron-based compressor valve plates are precision functional parts rather than simple structural components.

Technical Requirements for Iron-Based Compressor Valve Plates

Dimensional Accuracy and Flatness

Dimensional accuracy is essential for proper alignment of suction and discharge ports and consistent contact with valve reeds. In industrial production, length and width tolerances are typically controlled within ±0.03 mm to ensure reliable assembly and repeatable performance.

Among all geometric requirements, flatness is the most critical parameter for a compressor valve plate. For most compressor designs, the allowable flatness deviation of the sealing surface is limited to ≤ 0.04 mm after final processing. If this requirement is not met, localized leakage paths form during compression, reducing efficiency and increasing dynamic loads on the valve reeds.

Unlike thicker machined components, thin compressor valve plates are highly sensitive to thermal and residual stresses. As a result, flatness must be managed throughout forming and sintering rather than corrected solely by post-processing

Mechanical Performance Requirements

Iron-based compressor valve plates operate under repeated impact and fatigue loading. During each compression cycle, valve reeds strike the surface of the compressor valve plate, generating localized stress concentrations that accumulate over time.

To maintain dimensional stability and resist fatigue deformation, powder metallurgy iron-based compressor valve plates are typically designed with a density of about 7.0–7.2 g/cm³. This density range balances stiffness with defined porosity for damping and manufacturability.

Hardness is commonly held within the range of 60–65 HRB, balancing wear resistance with adequate toughness. Excessive hardness may increase brittleness and impact damage, while insufficient hardness accelerates surface wear and flatness degradation.

Mechanical properties and geometry are closely linked. High hardness alone, without flatness control, does not improve sealing performance, while insufficient density leads to progressive deformation during long-term operation.

Limitations of Conventional Manufacturing Processes

Traditional iron-based compressor valve plates are typically produced by stamping or fine blanking from steel sheet, followed by machining, heat treatment, and surface grinding. While this approach can achieve the required flatness of ≤ 0.04 mm, it relies heavily on secondary operations.

Material utilization is relatively low due to scrap generation, and repeated grinding introduces residual stress into thin plates with thicknesses around 3 mm. These stresses can cause distortion during heat treatment or extended service.

As compressor valve plate geometries become more complex and tolerances tighter, sustaining consistent flatness and dimensional accuracy across large production volumes becomes increasingly difficult using conventional methods.

Net-Shape Manufacturing of Iron-Based Compressor Valve Plates

Powder Metallurgy

Powder metallurgy achieves near-net-shape forming of iron-based compressor valve plates, delivering high material utilization and excellent repeatability. Through precise regulation of powder mixing, compaction density, and sintering parameters, PM processes can produce compressor valve plates with stable thickness and internal features while minimizing machining.

Optimized sintered compressor valve plates can achieve functional densities around 7.1 g/cm³, supporting both mechanical performance and flatness stability. More importantly, powder metallurgy allows flatness to be addressed during process design rather than relying on extensive post-grinding.

Sintering deformation remains a key challenge, but it can be mitigated through careful management of furnace conditions and part support.

After sintering process, sizing is applied to stabilize geometry and improve flatness, allowing powder metallurgy compressor valve plates to reach flatness levels typically around 0.02–0.03 mm, which is sufficient for direct functional use without heavy grinding. Steam treatment is then commonly used to form a dense oxide layer within surface-connected pores, enhancing airtightness at sealing interfaces while also providing effective corrosion resistance. Together, these well-defined secondary operations improve dimensional consistency, sealing reliability, and long-term durability in compressor applications.

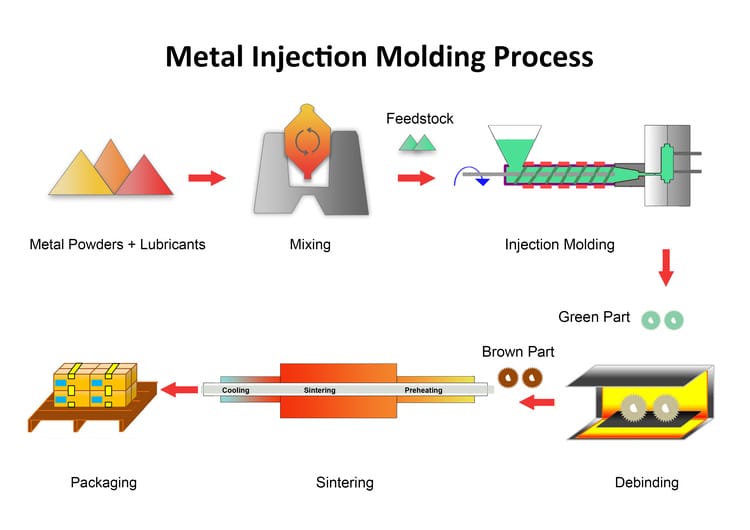

Metal Injection Molding

Metal injection molding is well suited for producing small, highly complex valve components that require fine surface finish and tight dimensional tolerances. The process enables near-full densification, with final densities reaching up to about 99%, resulting in excellent mechanical integrity and surface quality. However, for full-size iron-based compressor valve plates, metal injection molding is generally constrained by higher material and processing costs, as well as limitations related to part thickness and debinding efficiency.

Warm Compaction

Warm compaction improves green density uniformity by compacting powder at elevated temperatures, typically in the range of 130–150 °C, before sintering. This approach reduces density gradients within the compact and helps improve flatness stability while lowering sintering distortion, particularly for thin iron-based compressor valve plates. Warm compaction demands stricter management of tooling temperature and process consistency. In return, it enhances dimensional stability without fundamentally changing the powder metallurgy production route.

Factors Affecting Sintered Compressor Valve Plates

Furnace Loading Configuration

Furnace loading configuration plays a decisive role in sintering deformation. Uneven thermal exposure or improper stacking can cause warping that exceeds allowable flatness limits, even when material composition and compaction density are tightly governed.

Well-designed loading strategies, such as uniform spacing and balanced placement, help maintain flatness within functional requirements and reduce the need for corrective sizing or grinding.

Sintering Pressure and Assisted Sintering

Defined external pressure during sintering promotes densification and microstructural uniformity. Higher density enhances stiffness and fatigue resistance, supporting long-term flatness stability. However, excessive pressure can introduce new deformation risks, requiring careful process calibration.

Development Trends of Iron-Based Compressor Valve Plates

The development of iron based compressor valve plates is increasingly focused on reducing or eliminating post-grinding operations. Manufacturers are shifting toward integrating flatness into process design, stable density design, and consistent mechanical performance from net-shape manufacturing routes.

As powder metallurgy technologies advance, iron-based compressor valve plates are expected to transition from machining-intensive components to fully net-shaped functional parts, offering improved efficiency, lower cost, and higher production consistency.