Off-highway equipment faces dust, shock, vibration, and wide temperature swings. Powder metallurgy delivers near-net-shape parts with tight tolerances, repeatable properties, and low scrap. Alloyed Fe-based steels support case hardening or sinter hardening for high contact strength and fatigue resistance. Bronze and Fe-based porous bushings with oil impregnation provide stable tribology in contaminated service. The result is durable, cost-efficient components for steering, driveline, hydraulics, and chassis systems.

Contents

Powder Metallurgy Materials for Off Highway Vehicles

The following are commonly used powder metallurgy materials for manufacturing off-highway vehicle parts.

Iron‑Based Steels

Off-highway vehicle components are often manufactured using iron based PM steel which is sometimes alloyed with Chromium and Molybdenum. Iron-based PM steels are pressed into shape under elevated pressure, which makes the parts dense and strong. After shaping, the surface can be hardened through heat treatment, while the core stays tough and ductile.

Stainless Steel

Components for off-highway vehicles often operate in wet, muddy, or chemically aggressive conditions that can quickly degrade ordinary steels. Whereas stainless steel is known for its durability and corrosion resistance, even in harsh conditions. So, manufacturers prefer stainless steel such as 304, 316, 410 and 420 for the production of steering linkages, actuator housings, and fasteners.

Copper‑Based Materials

Copper-based PM alloys, such as Cu–Sn bronzes, are widely employed in bushings and bearings which are exposed to heavy loads and high contamination.Their oil-impregnated, self-lubricating structure reduces friction and wear. This keeps moving parts reliable even when external lubrication is limited.

Powder Metallurgy Components in Off Highway Vehicles

Seat Adjusters

Manufacturers use powder metallurgy (PM) to create compact and durable seat adjuster components that can endure continuous vibration, moderate impact forces, and frequent repositioning. Some complex parts such as gear racks, pivot brackets, levers, and oil-impregnated bushings are produced with superior dimensional accuracy.

Bearings

Bearings in off-highway vehicles are ideally manufactured using powder metallurgy (PM) due to its ability to deliver durable, wear-resistant, and self-lubricating components. These bearings are capable of withstanding stress, shock, and contamination from mud or dust. Oil-impregnated sintered bearings maintain lubrication in harsh environments. Whereas iron and copper-based PM materials provide excellent hardness and tribological performance. This makes them cost-efficient as well as reliable for steering linkages, suspension pivots, transmission shafts.

Lever Arms

Lever arms in suspension and linkage systems usually face cyclic stress. PM offers the ability to manufacture these parts with dense microstructures in addition to consistent mechanical properties. The manufacturer uses sinter-hardenable steels, due to which lever arms gain both surface hardness for wear resistance and a ductile core to absorb shocks. This balance helps extend service life in rugged terrains.

Pulleys

PM pulleys are produced with tight dimensional control, which ensures precise belt alignment. They can be designed with complex geometries such as integrated hubs or grooves—without extensive machining. Copper-infiltrated or alloy-strengthened iron grades improve wear resistance, making these pulleys suitable for elevated-load belt and chain drives in heavy machinery.

Steering Mechanisms

Steering linkages, housings, and mounts demands strength to withstand constant load reversals. Case-hardened PM steels provide strong surfaces against wear while maintaining toughness inside the part. This ensures steering remains responsive and durable, even in mud-laden or chemically aggressive conditions where corrosion is common.

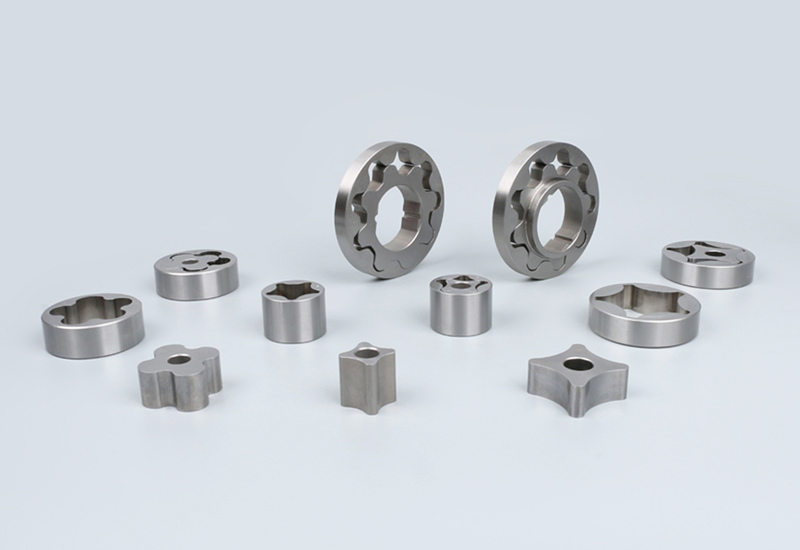

Oil Pump Rotors

Oil pump rotors are prime examples of where PM excels. They need precise geometry for controlled oil flow and consistent pump performance. PM enables the production of internal and external rotors with smooth profiles, minimizing leakage and pressure fluctuation. Typically made from iron-based PM materials, these rotors operate in a lubricated environment, ensuring durability and long service life.

Transmission Parts

Transmission systems demand gears, synchronizers, and hubs which combine wear resistance with toughness. PM gears can be surface-hardened to handle torque transfer. At the same time, their core remains ductile, preventing sudden failures under shock loads. This makes PM a cost-effective option for large-volume transmission parts while retaining exceptional reliability.

ABS Sensor Rings

ABS sensor rings necessitate high dimensional precision for accurate electronic signal generation. PM enables the integration of fine teeth and complex geometries directly during compaction, avoiding costly machining. Ferromagnetic materials such as pure iron or iron-based alloys are commonly used to ensure reliable interaction with magnetic sensors. Since these materials are prone to corrosion, protective coatings or surface treatments are typically applied to maintain performance in wet or muddy environments.

Advantages of Powder Metallurgy for Off‑Road Vehicle

Cost Efficiency in Mass Production

Die pressing and sintering are inherently scalable, enabling production of precise components with minimal scrap and lower energy usage. Thus delivering cost savings at automotive throughput volumes.

Reduced Vehicle Weight

PM’s ability to tailor density and integrate functionality into single parts supports lightweight designs. Aluminum PM parts reduce overall mass, directly contributing to lighter vehicles.

Lower vehicle weight reduces energy demand during acceleration and operation. This results in improved fuel efficiency and reduced emissions.

High Precision

PM yields consistent tolerances and dimensional repeatability even across long production runs, key for assemblies like steering linkages, sensor rings, and transmission modules.

Consistency Across Large Production Batches

Automotive parts often share multi-thousand-unit runs; PM ensures tight process control, homogeneous microstructure, and reproducible mechanical properties vital for dependable off‑road performance.