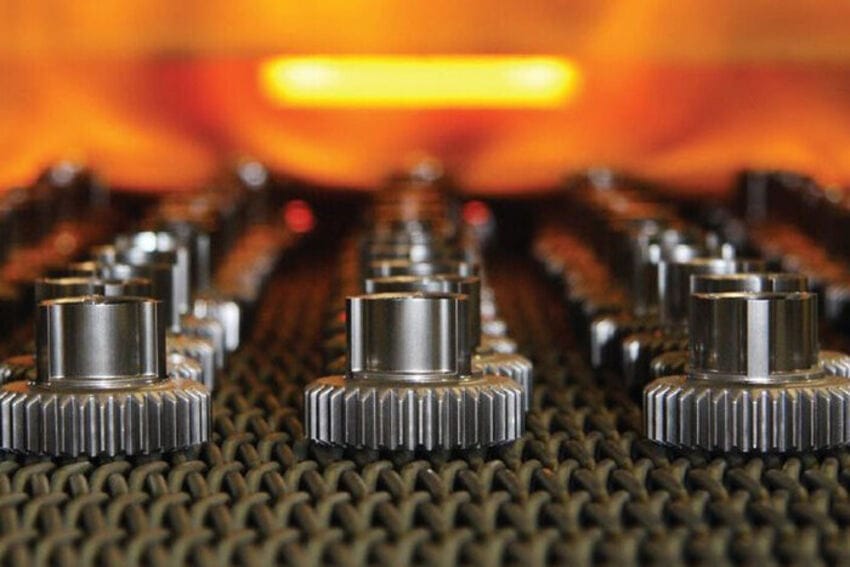

Powder metallurgy is a near net shape manufacturing process where metal powder is blended, compacted, and sintered at high temperature to produce durable components. The method produces near-net-shaped parts with consistent tolerance and minimal waste. This mix of precision and accuracy makes powder metallurgy process an ideal choice for manufacturing lawn and garden equipment, where volume and cost control are important.

Contents

Powder Metallurgy Applications in Lawn and Garden

Lawn Mowers and Self-Propelled Equipment

Clutch Systems

In lawn mowers, clutches, hubs, and shoes are manufactured using PM to ensure strength and wear resistance. Studies have shown that clutches made by powder metallurgy using Fe–Cu–C steels show high strength and wear resistance. The geometry of these components is formed directly during pressing, which eliminates the need for secondary machining.

Blade Adapters

Blade adapters of lawn mowers face sudden impact loads when striking complex objects. For this reason, these blade adapters require toughness and hardness to prevent deformation or failure. This is achieved by manufacturing these blades using sinter-hardened steels.

Pulleys and Drive Components

Sintered drive pulleys are used in these equipment to maintain dimensional accuracy, in order to reduce noise and vibration during mowing. Integrated hub features can be pressed directly into the pulley, reducing assembly steps and improving balance.

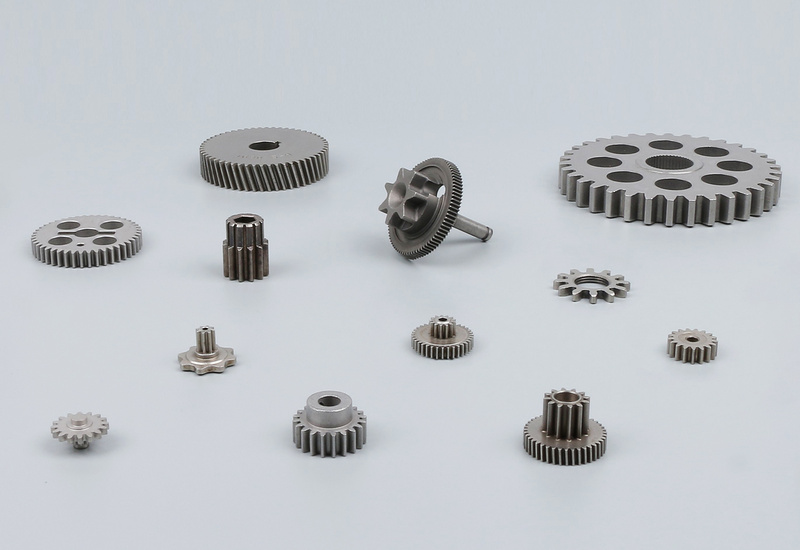

Trimmers, Edgers, and Electric Garden Tools

Electric garden tools such as trimmers and edgers operate at high rotational speeds. Powder metallurgy produces bearings, spacers, and sintered gears that maintain tight tolerances and balance. This precision is critical for reducing vibration and ensuring smooth performance of these tools. These components deliver durability with minimal additional machining, enabling consistent high-speed operation. For this reason, self-lubricating bearings are widely used in power tools and household appliances.

Snow Blowers and Seasonal Machinery

Hydraulic Linkages, Steering Mechanisms, and Seat Adjusters

Seasonal machines like snow blowers use multiple moving joints that require strength and wear resistance. The sintered compact bushings and adjuster components offer good repeatability of tolerances, which supports reliable operation in repeated motion. In cold environments, this dimensional consistency helps reduce the risk of seizing or premature wear.

Heavy-Duty Gears and Pulleys

Drive systems in snow blowers must transmit high torque under load. Sinter-hardened and alloyed PM steels are used for gears and pulleys because they combine hardness with toughness. The results are reliable operation, even when exposed to sudden impacts and low winter temperatures.

Speciality Outdoor Equipment

Hinge Mechanisms

Outdoor equipment, such as chippers and tillers, relies on hinge joints that undergo cyclic loads from constant opening and closing. In Powder metallurgy, hinges are formed with integrated pins or flanges, reducing welding and assembly steps.

Sprockets

Sintered sprockets provide uniform tooth geometry and consistent hardness. This ensures smooth chain engagement and longer service life under abrasive outdoor conditions.

Hubs

In heavy-use outdoor equipment, hubs act as the connection point between rotating shafts and driven components. Hubs manufactured through powdered metallurgy show precise bore alignment and integrated locking features. This reduces the chance of slippage under torque.

Garden Power Tools

Electric Chain Saw Gears

Electric chainsaws rely on precise speed control to keep cutting smoothly and safely. Powder metallurgy gears provide this consistency by maintaining uniform tooth geometry and balance.

Reciprocating Saw Bearings

Reciprocating saws usually operate under a rapid back-and-forth motion that generates high friction. That is why sintered oil-impregnated bearings are used here to form a thin lubricating film during use. This not only reduces wear without external grease but also offers quieter operation, longer bearing life, and less downtime for maintenance.

Benefits of Powder Metallurgy Applications in Lawn and Garden

Enhanced Durability

Lawn and garden equipment often faces dust, moisture, vibration, and seasonal storage. That’s why their components must be reliable enough to bear all these conditions. Ferrous powder metallurgy parts treated with Dacromet or steam treatment exhibit excellent corrosion resistance and enhanced durability.

High Precision and Complex Geometry Capabilities

Outdoor equipment relies on assemblies where tight fits and consistent geometry matter. Blade adapters must lock firmly to shafts, sprockets need tooth forms that mesh smoothly, and pulleys require balance to avoid vibration. Powder metallurgy achieves this precision directly during compaction.

Cost-Effective and Sustainable Manufacturing

PM offers durable and affordable manufacturing of lawn and garden tools by maximising material utilisation and minimising material waste. Because PM compacts nearly all the powder into the final shape, and the waste produced is recyclable back into the process.

Lightweight and Strength

Portable garden tools, trimmers, and electric saws require lighter assemblies that still deliver strength. Powder metallurgy makes this possible through feature consolidation and selective density control.

BLUE is a dedicated powder metallurgy supplier with 20 years of manufacturing experience. We provide a full range of precision parts for lawn and garden tools. Standard parts are available with no tooling fees and can be ordered directly from our SHOP. For unique requirements, we also deliver custom solutions tailored to your applications.