Heat treatment is a controlled thermal process consisting of heating, holding, and cooling cycles to modify the microstructure and mechanical properties of metallic materials. In powder metallurgy (PM) components, heat treatment is applied to enhance hardness, tensile strength, and wear resistance by refining grain structure and promoting phase transformations.

Contents

Benefits of Heat Treatment for Powder Metallurgy Parts

Higher Surface Hardness and Wear Resistance

When specific heat treatments are applied to the powder metallurgy parts, they enhance the surface hardness as well as wear resistance of the components. For example, by carburizing the metal components under a high-carbon atmosphere, carbon is incorporated into its microstructure.

Then, upon quenching, the carbon enrichment structure transforms into hard martensite. After this heat treatment, the surface hardness of the sintered component falls in the range of HRC 58–65, making it tough and resistant against an abrasive atmosphere.

Higher Strength and Fatigue Life

Tensile strength and fatigue life can be improved through controlled heat treatment on powder metallurgy parts, such as quenching followed by tempering.

Heat treatment can significantly improve the tensile strength and fatigue strength of powder metallurgy steels. A PM heat treatment study on cold work tool steel found that adding a −80 °C sub-zero step between quenching and tempering refined carbide distribution increased tensile strength by about 10% and notched fatigue strength by roughly 25%. Such results highlight the value of advanced heat treatment in enhancing these critical properties for PM parts under cyclic loads.

Toughness Tuning

Some heat treatments are applied to metal components to make their surface tough while keeping the internal core soft, such as induction hardening. The tough core increases their lifespan by making them resistant to wear, whereas the tough core allows them to bear high loads without cracking. Typical applications include oil pump gears and timing sprockets.

Stress Relief

Low-temperature annealing is commonly used to relieve residual stresses in powder metallurgy components, which can form during compaction, sintering, or machining. This treatment stabilizes the microstructure, minimizes distortion risks, and enhances dimensional accuracy.

Heat Treatment Methods for Powder Metallurgy Parts

Quenching

Quenching is a treatment in which the powder metal components are heated to an austenitizing temperature (often 800–950 °C for steels) and then cooled rapidly using a quenching medium such as oil, water, or gas. The sudden cooling suppresses the formation of softer phases such as pearlite or bainite, transforming austenite into martensite and thereby increasing the hardness, strength, and wear resistance of the material.

As a result, the strength and wear resistance of components increase. Although the process improves the strength and hardness of the metal part, the rapid cooling creates stress, increasing brittleness or reducing toughness. That’s why quenching is followed by tempering to restore toughness. Quenching is applied to gears, cutting tools, and machinery tools where hardness and wear resistance are key.

Tempering

Mostly tempering is performed on those components that have been subjected to quenching, where the hardness and strength increase, but the toughness decreases, making the component more brittle. Tempering maintains a balance between toughness and ductility.

In tempering, the components are first heated below their critical temperature for a certain period of time. The tempering temperature depends upon the composition of elements such as

- Tool steels are tempered at around 200-300°C

- Spring steels at 300-400°C and

- Structural steels at 450-650°C

After a special dwelling period, these components are then cooled at a controlled rate according to the required mechanical properties. This process increases ductility and flexibility while reducing brittleness, ensuring the part can handle impact and cyclic loading without failure.

Annealing

Annealing is a heat treatment process applied to powder metallurgy components to improve machinability and relieve stresses generated during compaction and sintering. Unlike quenching, which increases hardness, annealing produces a softer, more ductile microstructure.

For powder metallurgy steels, the annealing parameters—such as temperature range, holding time, and cooling method—vary depending on the material type. For example for low alloy steel whenever annealing is required, it is commonly carried out at a temperature of 830–870 °C, followed by furnace cooling to about 450 °C at a rate of 10–15 °C per hour, before air cooling. This gradual cooling transforms the microstructure, reducing hardness while enhancing dimensional stability and ductility.

Annealing is commonly used for bushings, bearing sleeves, and structural components where stability and toughness are prioritized over maximum hardness.

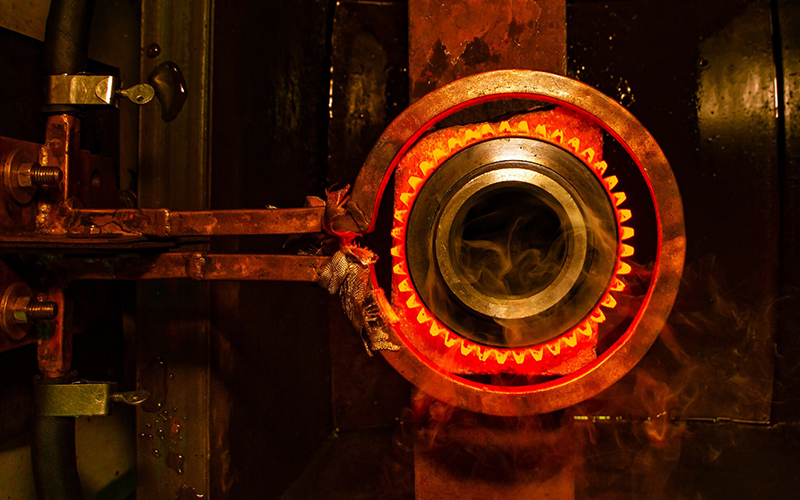

Induction Hardening

Induction hardening is a surface heat treatment method in which powder metallurgy components are heated rapidly by electromagnetic induction, typically 800–950°C for steels. The process uses a high-frequency alternating current passed through a copper coil.

This current generates eddy currents in the component’s surface and heats its surface to a temperature above the austenitizing temperature point. After reaching the desired temperature, the component is immediately quenched, transforming the heated layer into a hard martensitic case while keeping the core tough and ductile.

Case Hardening

Case hardening includes different heating processes that harden the metal components from the surface while keeping its core ductile and tough.

Carburizing

In carburizing, the metal components are subjected to a carbon-rich atmosphere in a furnace at 850°C and 950°C. The source of carbon is usually methane or carbon monoxide, which diffuses into the surface layer of the component. This changes the surface microstructure and, after quenching, produces a hard martensitic case that greatly increases wear resistance and surface hardness.

Nitriding

In nitriding, the components are introduced in a nitrogen-rich environment either by using a furnace with ammonia or in a plasma nitriding unit. Here, the temperature of furnaces is kept lower than carburing, it’s about 500°C to 600°C, resulting in nitride formation. As a result, Nitrogen combines with alloying elements to form hard nitrides, improving surface hardness, fatigue strength, and corrosion resistance. Nitriding is typically done for the components that need to work under high stress, such as crankshafts and camshafts.

Carbonitriding

Carbonitriding is also a surface hardening process where the components are subjected to a carbon and nitrogen-containing atmosphere simultaneously. Hydrocarbon gases provide the carbon source, while ammonia supplies nitrogen. The temperature of the furnace is kept below the transformation temperature of the material, such as for steel, it is kept between 820-900°C.

This results in the formation of hard components like iron nitride and carbide, which are responsible for an increase in surface hardness, wear resistance, and fatigue. After carbonitriding, the components are typically subjected to quenching to lock in the hardened microstructure, followed by tempering to reduce brittleness and achieve the desired balance between hardness and toughness.

Sinter Hardening

Sinter hardening is the heat treatment of powder metal components, where the components are both sintered and hardened with the same process. Here, the components are first heated to an elevated temperature for sintering and then subjected to accelerated cooling.

This accelerated cooling converts microstructure directly into martensite or a martensitic–bainitic mix, eliminating the need for a separate quenching operation. As a result, this process reduces production time, lowers handling costs, and minimizes distortion. This heat treatment is applied to gears, sprockets, and structural components requiring high wear resistance and strength directly after sintering.

Aging Treatment

Aging treatment is a heat treatment process, which is also referred to as precipitation hardening, in which the fine metal particle precipitates within the material microstructure. These finely dispersed precipitates act as barriers to dislocation movement, significantly enhancing hardness and strength. This process enables the material to resist deformation at high temperatures, making it thermally stable.

Looking for Precision Powder Metallurgy Solutions?

BLUE is a leading powder metallurgy manufacturer in China, delivering high-quality standard sintered components with no tooling costs. Explore our SHOP to find parts that match your exact requirements. We provide a full range of secondary operations, including heat treatment, precision machining, sizing, copper infiltration, and more. For unique needs, our custom powder metallurgy services deliver tailored solutions with tight dimensional control and consistent quality.