A spur gear is a cylindrical gear with straight, involute teeth that run parallel to the shaft axis. It transmits motion and power between two parallel shafts while handling both radial and tangential loads without producing axial thrust. Known for their simple construction, high efficiency, and low production cost, spur gears are among the most widely used types of gears in mechanical systems.

Contents

How do Spur Gears Work?

Spur gears work by meshing the teeth of the driver gear with the driven gear. Here are the steps showing how a spur gear works:

Teeth Contact

When two spur gears are placed side by side, their teeth come into contact along the face of the gear. Here, the teeth of the driver gear push against the driven gear teeth.

Transferring Force and Rotation

As the force is applied by the driver gear, it transfers torque to the driven gear, which is tangential to the gear’s base circle. This results in the rotation of both gears in opposite directions, with their angular velocity remaining constant.

Torque and Speed Adjustment

The torque and speed of the rotating spur gears depend on the ratio of the number of teeth of the driven and driving gears.

- A larger driven gear results in slower rotation but higher torque.

- A smaller driven gear results in faster rotation but lower torque.

Types of Spur Gears

External Spur Gear

In an external spur gear, the teeth are present on the external diameter of the gear. The teeth of two external gears mesh together, and they rotate in opposite directions. Here, the larger gear is termed the wheel, and the smaller one is referred to as the pinion

Internal Spur Gear

An internal spur gear is one of the types of gears where the teeth are carved into the internal diameter of the gear. These gears usually work in combination with external gears, such as in planetary gear systems. The larger gear here is called an annular wheel, while the smaller one is referred to as a pinion.

In the internal gear system, both the drive and driven gears rotate in the same direction. When an internal gear meshes with an external gear, they have a high contact surface area, resulting in reduced stress and increased torque transfer. The teeth engagement of the internal gear is more stable, resulting in less sliding and making it suitable for high-load bearings.

Materials for Spur Gears

Plastic

Spur gears can be manufactured using plastic such as acetal and nylon. These gears are lightweight, noise-free, and resistant to corrosion. Gears produced from such materials are suitable for low-speed and low-load applications.

Stainless Steel

Stainless steel is used for manufacturing gears to be used in low load environments where corrosion resistance is a priority. However, it is not a common choice because it lacks hardness and is more susceptible to wear compared to other materials.

Cast Iron

Cast iron is one of the most commonly used materials for manufacturing spur gears. Cast iron is relatively easy to machine and cost-effective, although it is more brittle compared to steel.

Aluminum Alloy

Aluminum alloy is used for the manufacturing of gears where a high strength-to-weight ratio is required, such as in the aerospace industry.

Powder Metallurgy Materials

Common powder metallurgy materials for spur gears are iron-based metal powders. Typical grades include FC-0205 (Fe-Cu), FN-0205 (Fe-Ni), and FD-0205 (diffusion alloyed Fe-Cu-Ni).

What are Spur Gears Used For?

Automotive Industry

Spur gears are used in automobiles for transferring power from the engine to the wheels. They are commonly found in:

Rack and Pinion System

A key application of spur gears is in rack and pinion systems to convert rotational motion into linear motion. The rack and pinion spur gear system consists of two main parts: the pinion, which is a round gear, and the rack, which is a flat, straight gear with teeth. When the pinion rotates, its teeth engage with the teeth on the rack, causing the rack to move in a straight line. These spur gears are commonly used in the steering systems of cars.

- In manual and automatic transmissions, these are used to change speed and torque.

- In differential gears, they allow wheels to rotate at different speeds while turning.

- Power steering systems

Aerospace and Aviation

In aerospace, spur gears are used in engines to control the movement of various parts. Not only this, they are also used in the landing gear of aircraft.

Power Generation

Spur gears play a crucial role in the production of electricity by helping transfer mechanical energy to the generator, such as in wind turbines or steam turbines.

Industrial Machinery

Spur gears also find application in many heavy-duty industrial equipment, such as gearboxes, compressor systems, and mills.

How are Spur Gears Made?

Here are some common gear manufacturing process for spur gears:

Milling

In this process, the spur gears are produced by cutting teeth directly into a gear blank using a milling machine and a form cutter that matches the tooth profile. For this purpose, the gear blank is fixed on an indexing head. This head rotates it one tooth pitch at a time as the cutter shapes each tooth. This method is excellent for small batches, prototyping, and custom gears.

Hobbing

Hobbing is used for the manufacturing of accurate and efficient spur gears in various sizes and applications. Here is how spur gears are produced:

- A gear hobbing machine includes two angled spindles: one for the rotating cutting tool (the hob) and another for the gear blank.

- First, the angle between the two spindles is adjusted based on the gear type being produced, such as for spur gears.

- Now the hob and gear blank are rotated at a synchronized speed ratio appropriate for the desired gear tooth geometry.

- As the hob spins and feeds into the blank, it progressively carves out gear teeth with the correct shape and depth.

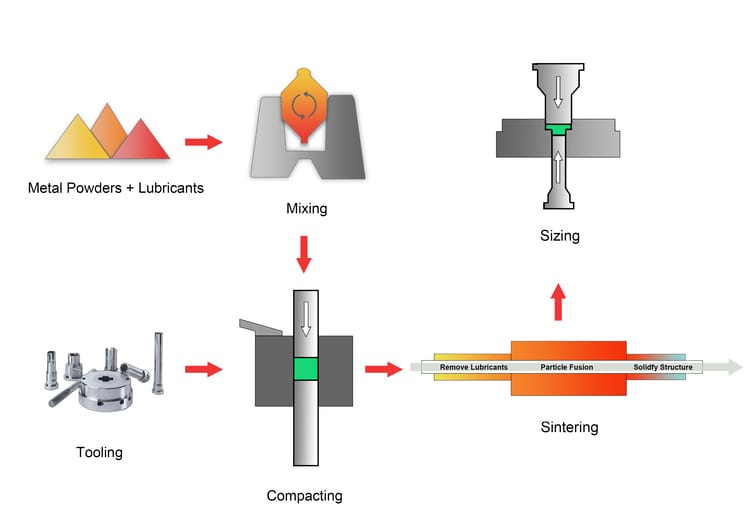

Powder Metallurgy (PM)

You can efficiently produce spur gears using the powder metallurgy process. First, you press metal powder into a die using upper and lower punches to form the gear shape. The compacted part, called a green compact, is then sintered at high temperature to achieve the required strength and material properties

Compared to machining, powder metallurgy gears achieve a much higher material utilization rate of around 95%, whereas traditional machining typically yields only about 70%.

The PM process is an ideal method for producing spur gears with tight tolerances, consistent quality, and low production waste, especially for large-scale production.

Forging

Forging is a manufacturing method used to create gears, where the component is subjected to high heat and pressure to achieve the desired die shape. This method is used for both gear blanks and toothed gears. Gears made using this method offer high strength and fatigue resistance. However, they may require additional machining for precise finishing. This method is suitable for producing spur gears for heavy-duty applications.

Cold Forming

Cold forming is one of the cost-effective gear manufacturing processes due to its high production rates. It is a versatile method used for the mass production of spur gear elements.

In this process, a metal bar (called a blank) is pulled (drawn) or pushed (extruded) through a series of dies. The final die has the exact gear tooth shape as required.

As the bar moves through the dies, it is compressed and reshaped under high pressure.

Advantages of Spur Gears

- Spur gears have a simple design that makes them easy to manufacture and maintain.

- These are cost-effective due to their simple design and ease of machining compared to helical gears.

- Spur gears show high efficiency (typically between 95–99%) with minimal power loss.

- These gears have a smooth motion due to a constant velocity ratio.

- These gears are reliable and durable when operated under proper conditions.

- Spur gears are capable of handling high loads, especially at moderate speeds because of direct tooth contact and their robust design.