Mohs Hardness Test is one of the most common ways to assess the hardness of materials. Understanding material hardness helps engineers and professionals choose suitable substances for specific uses, ensuring durability and performance. This field-friendly, straightforward method has been in use for over two centuries and plays a key role in education, mineralogy, and various industries, providing a quick and cost-effective means to evaluate a material’s scratch resistance.

Contents

What Is the Mohs Hardness Test?

The Mohs Hardness Test is a scale that ranks the hardness of minerals based on their ability to withstand scratching. In simpler terms, it measures how easily a mineral can be scratched by another substance.

The test is based on the principle that a harder material can scratch a softer one, but not the other way around. For example, if mineral A can scratch mineral B, then mineral A is harder. If it can’t, then mineral B is harder, or equal in hardness.

This method was developed in 1812 by Friedrich Mohs, a German geologist and mineralogist. He created a scale of 10 minerals with clearly defined hardness values, ranging from the softest (talc) to the hardest known natural material (diamond).

Mohs Hardness Scale

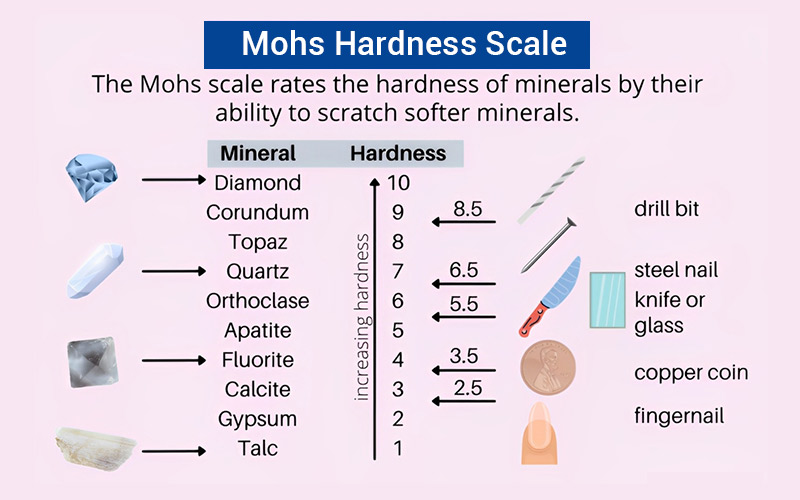

The Mohs Scale of Hardness ranks minerals on a scale from 1 to 10, with 1 being the softest and 10 the hardest. Each number on the scale represents a reference mineral with a known hardness.

Mohs Hardness Chart

The Mohs scale is not linear because it does not indicate a proportional increase in hardness, even though they are a step apart numerically. For example, from Calcite (3) to Fluorite (4) indicates about 50% increase, while Corundum (9) to Diamond (10) reflects about 275% increase.

| Mohs Hardness Level | Absolute Hardness Level | Mineral |

|---|---|---|

| 1 | 1 | Talc |

| 2 | 2 | Gypsum |

| 3 | 14 | Calcite |

| 4 | 21 | Fluorite |

| 5 | 48 | Apatite |

| 6 | 72 | Orthoclase Feldspar |

| 7 | 100 | Quartz |

| 8 | 200 | Topaz |

| 9 | 400 | Corundum |

| 10 | 1500 | Diamond |

Mohs Hardness Test Procedure

The procedure for conducting a Mohs hardness test is simple and often requires minimal equipment. It’s usually performed using a Mohs hardness test kit, which includes reference minerals or tools of known hardness.

Mohs Hardness Test Kit

- Fingernail (2.5)

- Copper coin (3)

- Knife or steel blade (5–5.5)

- Glass plate (5.5–6)

- Steel file (6.5)

- Set of Mohs picks (commercial kits)

Sample Preparation

Select a flat, clean surface on the mineral or unknown material.

Perform the Scratch Test

Try to scratch it using the point of a reference mineral or object of known hardness, for example, a fingernail, the edge of a copper penny, the tip of a steel file, etc. Scratch by pressing the reference material into the test sample and dragging across it to make a dent.

Observe the Scratch

Examine the test sample for a scratch by either looking at it or feeling for it with your fingers. A real scratch will leave a groove; a false mark can often be wiped away. If your sample is successfully scratched, then the tester is harder than the sample; otherwise, the sample is harder than the tester.

Test Again

If the test sample is not successfully scratched, repeat the test with progressively harder reference tools until you find one that scratches and/or one that doesn’t. Make sure you repeat the scratch test using the sharp surface of the tester on a fresh surface of the test sample.

Conclude the Findings

Estimate the hardness based on the hardest material that cannot scratch the sample and the softest that can. For example, if you scratch your sample with a knife, then its hardness is less than 5.5, but if a copper coin cannot scratch it, the sample is most likely on the same hardness level as the coin.

Applications of Mohs Hardness Test

The Mohs test, while not precise enough for detailed industrial testing, is effective for early-stage assessments and widely used in multiple fields due to its simplicity and practicality.

Geology and Mineralogy

Geologists and mineralogists use the Mohs hardness scale to identify unknown minerals directly in the field.

Gemology

In gemology, the scale serves as a reliable tool for confirming gemstone authenticity and determining how well gems resist scratches.

Construction

Construction professionals apply the scale when evaluating tiles, stones, and ceramics for durability and suitability in spaces like kitchens, countertops, and wall panels.

Manufacturing and Coatings

Manufacturers and coating specialists depend on hardness data to select materials and finishes that can withstand surface wear and maintain performance over time.

Mohs Hardness Test Benefits

Simple to Use

This method is straightforward and doesn’t demand extensive training or complex equipment.

Cost-Effective

Affordable test kits or DIY approaches help keep expenses low for users.

Non-Destructive

It leaves most of the sample untouched, requiring only a minor scratch for assessment.

Portable

Thanks to lightweight tools and minimal technology, it’s perfectly suited for on-site work in the field.

Mohs Hardness Test Limitations

Not Precise for Engineering

Unlike Rockwell or Vickers tests, the Mohs method doesn’t deliver precise or quantitative hardness values needed for engineering applications.

Subjective Scratch Results

Outcomes can differ depending on how the test is performed or the current state of the material.

Non-Linear Scale

The Mohs scale isn’t proportional; for example, diamond is vastly harder than corundum despite being just one step higher on the scale.

Surface Condition Sensitivity

Altered or weathered surfaces may lead to misleading hardness readings.

Confusion Between Hardness and Toughness

Hardness shouldn’t be mistaken for toughness; certain materials, like glass, are hard yet prone to breaking under stress.For engineering applications requiring accurate data, more advanced tests are recommended.

Mohs vs. Other Hardness Tests

The following table highlights key differences between the Mohs hardness test and other hardness testing methods like Rockwell, Vickers, and Brinell.

| Feature | Mohs | Rockwell | Vickers | Brinell |

|---|---|---|---|---|

| Type | Qualitative | Quantitative | Quantitative | Quantitative |

| Method | Scratch test | Indentation depth | Indentation size (micro) | Indentation size (macro) |

| Field Use | Yes (portable) | No (lab-based) | No (lab-based) | No (lab-based) |

| Accuracy | Low | High | Very High | High |

| Common Use | Minerals, gemstones | Metals, plastics | Thin films, coatings | Softer metals, wood |

| Equipment Cost | Low | Medium to High | High | Medium |

The Mohs test is best for quick, qualitative field testing, while the others are more suitable for industrial and laboratory precision.

FAQ

Where Can I Buy A Mohs Hardness Test Kit?

The Mohs hardness test kit can be purchased from either specialty suppliers like Mineralab or the online market like Amazon, eBay, or Ubuy. Most of them come fully packaged including options with mineral specimens.

Is There a Standard That Regulates the Mohs Hardness Test?

Yes, the ASTM C1895 “Standard Test Method for Determination of Mohs Scratch Hardness” is the governing document for scratch-hardness testing. Therefore, it can be used to regulate the Mohs hardness test.