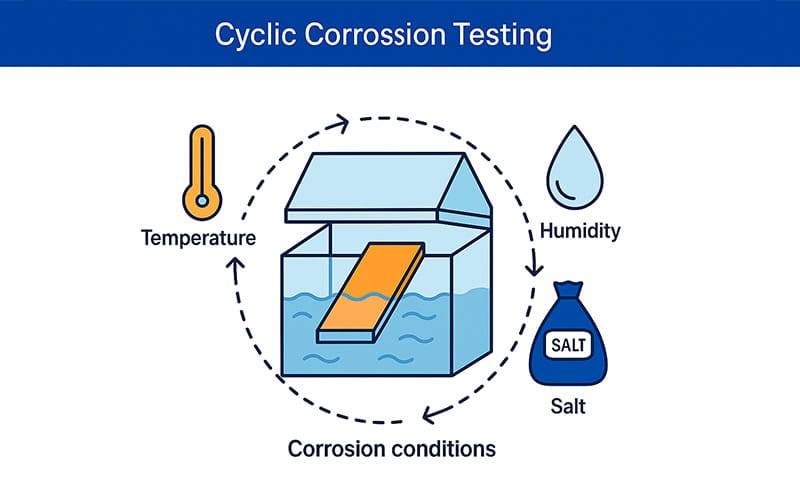

A cyclic corrosion test (CCT) is a laboratory corrosion test used to evaluate how well materials or coatings resist corrosion under conditions that better simulate real environments than salt spray tests. In this method, components are exposed to alternating cycles of salt fog, humidity, and dry periods, helping engineers quickly assess reliability and performance for various industries.

Contents

Working Principle of Cyclic Corrosion Testing

CCT works on principle of repeated exposure of components to multiple conditions including salt spray, moisture, humidity and varying temperature. Basically this technique works by simulating real world conditions either dry or wet to check how much a component is affected by these conditions. The main purpose of this testing is to accelerate the real world conditions in the lab to check the components reliability more efficiently.

Cyclic Corrosion Testing Procedure

Component Preparation

First of all the component to be evaluated is cleaned and dried properly so their is no dirt or debris which can hinder proper evaluation.

Setting Up the Instrument

In cyclic corrosion testing, the most important step is to set up the instrument properly and load the components to be tested in the instrument. This specific step usually depends upon the material type and which testing standard is applied.

Cyclic Exposure Simulation

After placing the components into the closed chamber the considerations are set such as humidity, salt spray, temperature variations, air pressure etc.

Corrosion Test

Now the test is run which can take as short as 24 hours or as long as more then one week depending upon the standard under which the test is being performed. The number of cycles of a cyclic corrosion test usually vary from 40 to 100 cycles.

Interpreting The Results

After the test is complete the sample is now taken out from the chamber and cleaned to stop any further reactions. Now the sample is analyzed for corrosion,peeling off, blistering or pitting. To evaluate the result the corrosion rate is determined if it exceeds the specified limit it means the component failed the corrosion test.

Cyclic Corrosion Testing Standards

Here are some common cyclic corrosion testing astm standards.

| Standard | Application Area | Description |

|---|---|---|

| ASTM B117 | Metal and Coatings | Salt spray test procedures for metallic materials and coatings. |

| ASTM G85 | Metals and Coatings | Cyclic corrosion under wet-dry, salt spray, and humidity exposure. |

| ASTM G44 | Metals and Coatings | Immersion corrosion using alternating wet and dry conditions. |

| ASTM D5894 | Automotive Coatings | Cyclic testing of automotive coatings in corrosive environments. |

| DIN EN ISO 11997 | Automotive Coatings | Procedures for cyclic testing including salt spray, drying, and condensation. |

| ISO 9227 | General Corrosion Testing | Salt spray test for evaluating corrosion resistance of materials and coatings. |

| ISO 7253 | Outdoor Exposure | Weathering tests with cyclic conditions simulating outdoor environments. |

| ISO 16701 | Automotive Components | Cyclic chamber testing for salt spray, humidity, drying, and condensation. |

| ISO 14993 | Paints and Varnishes | Corrosion testing of coatings in aggressive environments. |

| ISO 16151 | Metallic Coatings | Guidelines for cyclic corrosion testing with salt spray, drying, and humidity. |

Cyclic Corrosion Testing Cycles

Here, the most common Cyclic corrosion cycles

Prohesion Test

Prohesion is a type of cyclic corrosion test developed to evaluate the durability of industrial coatings., such as to detect filiform corrosion. In this cycle:

- The electrolyte used is a diluted mixture of 0.05% sodium chloride and 0.35% ammonium sulfate

- pH range of 5.0 to 5.4

- The cycle includes one hour of salt fog exposure at 25 ±1°C followed by a one-hour dry-off period at approximately 23 ±1°C using fresh air to remove moisture. This two-hour cycle is repeated continuously.

Corrosion/Weathering Cycle

This is the enhanced version of the prohesion test where the sample is exposed to UV radiation to check its effect on degradation. In weathering cycle

- The electrolyte is the same as in the Prohesion test

- pH is between 5.0 and 5.4

- The cycle includes one hour of salt fog at 25°C, one hour of dry-off at 35°C, four hours of UVA-340 UV light exposure at 60°C, and four hours of pure water condensation at 50°C. This sequence is repeated weekly, with the total test duration reaching 2000 hours.

GM 9540P/B Cycle

This cycle is mostly used in the automotive industry to evaluate the durability of paint coatings over metal parts. In this cycle:

- The electrolyte is a mixture of 0.9% sodium chloride, 0.1% calcium chloride, and 0.25% sodium bicarbonate

- pH between 6.0 and 8.0.

- The cycle includes multiple applications of salt mist, each followed by ambient rests of 90 to 210 minutes at 25°C and 30–50% relative humidity. This is followed by 8 hours in 95–100% humidity and 8 hours of dry-off at 60°C and less than 30% relative humidity. The test is performed for 80 cycles or approximately 1920 hours.

Acid Rain CCT

This test simulates environments influenced by acid rain based on modified JASO M609 guidelines.

- The electrolyte is a complex mixture containing 5% sodium chloride, 0.12% nitric acid, 0.173% sulfuric acid, and 0.228% sodium hydroxide

- With a typical pH value between 3.2 and 3.4, depending on the exact chemical formulation used.

- Each cycle consists of 2 hours of salt fog at 35°C, 4 hours of dry-off at 60°C with less than 30% relative humidity, and 2 hours in wet/humid conditions at 50°C with over 95% relative humidity. Transition times are defined: fog to dry within 30 minutes, dry to wet within 15 minutes, and wet to fog within 30 minutes.

Advantages of Cyclic Corrosion Testing

Better Correlation with Outdoor Conditions

CCT offers more conditions for conducting corrosion tests by repeated exposure to wet and dry conditions and changing temperature. As a result it provides more authentic results compared to other traditional corrosion testing methods.

Effective for Multiple Corrosion Types

CCT offers versatility and can be used for the evaluation of multiple corrosions, including general, galvanic, crevice, and filiform corrosion, more effectively than traditional tests.

Faster Material Qualification

The real-world conditions are accelerated in cyclic corrosion testing which provides faster results without taking too much time. This reduces the need for long-term outdoor field testing.

Enhances Material Selection and Design

CCT data supports informed decision-making in material and coating selection for specific applications. Engineers can compare different formulations and optimize design tolerances against corrosion damage.

Cyclic Corrosion Testing Technical Challenges

- Airflow disruption is one of the main challenges seen in CCTit, which caused uneven temperature and humidity distribution and led to unreliable results. This happens when the chamber is overfilled

- Another challenge in CCT is accurate fog deposition, which is difficult to measure during short CCT fog cycles. That is why it is essential to verify uniformity through dedicated continuous spray runs to ensure reliable test conditions.

- A little disruption in the cycle by improper storage or handling of specimens can introduce variability in corrosion data. As a result, the test reproducibility is affected remarkably.

Application of Cyclic Corrosion Testing

Automotive Industry

In the automotive industry, CCT is used to evaluate the corrosion resistance of painted and coated parts such as body panels and brake systems.

Aerospace Industry

In the Aerospace industry, it is applied to components like landing gear and wing fasteners to simulate cyclic humidity, salt fog, and temperature changes.

Military Sector

CCT ensures the durability of coated hardware, weapons mounts, and vehicle fixtures. It is done by exposing components to extreme cyclic environments involving salt spray and UV exposure.

Electronics

High humidity and salt-laden air condition are used to inspect electronic components such as circuit boards, terminals, and enclosures.