Material jetting is a 3D printing additive manufacturing technique that is used to manufacture 3d components layer by layer.Material Jetting (MJ) enables the manufacturing of components with highly accurate geometry and smooth surface finishes.This advanced manufacturing technique has grabbed the attention of engineers due to its remarkable properties. MJ is now used in various industries, including Automotive, Aerospace, and Medical Industries, for both prototypes and manufacturing purposes.

Contents

What is Material Jetting 3D Printing?

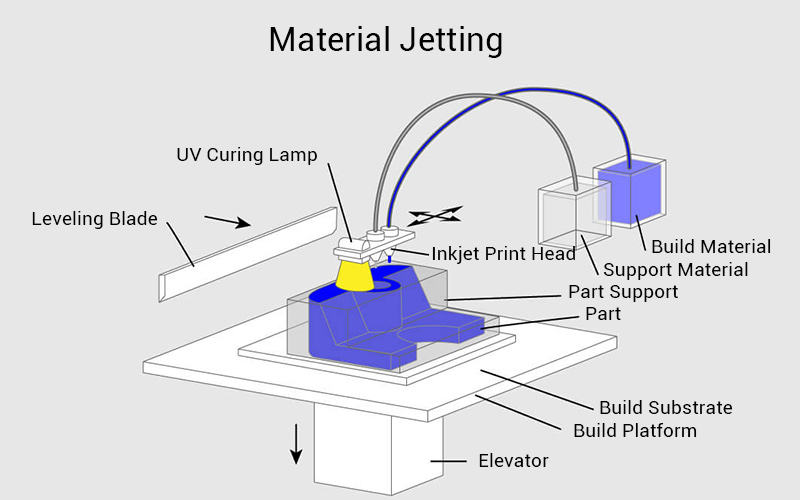

In the material jetting 3d printing process, the material is jetted on a built platform by using an inkjet head with controlled movement, just like in 2d printing. This photosensitive material is then hardened using UV radiations to obtain a precise component with a typical tolerance of ± 0.3mm and precise component. Numerous materials can be used to manufacture the components, such as waxes, polymers, ceramics, or even metals.

How Does Material Jetting Work?

Material Preparation

The first step in the material jetting process is the preparation of raw material, where the photopolymer resin is heated to 30–60°Cto reduce viscosity. This will ensure the optimal flow of the resin while jetting.

Droplet Deposition

The material is then loaded to the printhead, and this printhead then moves across the build platform. The inkjet head releases hundreds of tiny droplets of resin at specific locations according to the model’s slice geometry. The injection mechanisms which is followed is:

- Piezoelectric jetting is applied to non-volatile materials.

Layer Curing

As soon as the droplet reaches to build the platform the final curing of the layer formed is done either by heating the layer or by UV radiation. As soon as the droplets land on the tray and cure instantly under on-board UV-LEDs.

Surface Smoothing

In some wax-based systems, a fly cutter may pass over the printed layer to ensure a flat and even surface before the next layer is applied.

Platform Movement

As the curing of the first layer completes, the plate form moves down by one layer, making room for the next layer to be deposited.

Layer by Layer Printing

Now the previous steps such as jetting the material and its solidification is repeated until the whole component is manufactured according to a 3d sliced model.

Multi-Material Printing

Multiple print heads can be aligned side by side to deposit different materials simultaneously. This enables multi-material, full-color, and support structure printing in a single pass.

Support Removal

The support structure is used in the Material jetting 3d printing process which is usually made up of the dissolvable material. This support structure is removed in post-processing either by immersing into an ultrasonic bather or by pressurized water.

Material Jetting Machine

The material jetting machine combines precise micro-nozzles, UV curing, and controlled temperature to accurately deposit and solidify liquid materials layer by layer.

Print Head with Micro Nozzles

Material Jetting system consists of a print head that has an array of ultra fine nozzles. These nozzles eject tiny droplets of the material in a controlled way over the built platform.

Material Reservoir

Material reservoir of this system is also known as a Cartridge. It is a container that holds the liquid material. These reservoirs are either manually refilled or come as sealed cartridges to ensure safe handling.

UV Curing System

This is the source of UV radiation located near the print head. It provides UV radiations of required intensity of curing the liquid material into a solid layer.

Heated Build Chamber

In the case of NJP where ceramics and metals are used for jetting a heated chamber is present. This chamber is used to maintain the temperature for optimal evaporation and coalescence.

Types of Additive Manufacturing Material Jetting

PolyJet Technology

PolJet is one of the most common types of additive manufacturing material jetting where a thin layer of photopolymer is spread on a build tray and cured using UV radiations. The system uses a wide array of nozzles to deposit material precisely and quickly across the build surface. It can be used to print multiple materials and colors at a time resulting in high-resolution visual prototypes and over-molded parts.

Characteristics

- PolyJet offers very high resolution, with layer thickness as low as 14–16 microns.

- It produces parts with refined finish and fine details.

- It supports multi-material and multi-color printing in a single build.

- It enables the production of thin walls and intricate geometries.

NanoParticle Jetting (NPJ)

NPJ is a material jetting 3d printing process which uses suspension of metal or ceramics for the manufacturing of components or models. In this process the materials are supplied to the ink jet head by using a seal cartridge. Instead of Uv radiations a heating source is used for solidifying the layer of material particles. The components obtained are then sintered to form the final part.

Characteristic

- NPJ delivers exceptional feature resolution and surface smoothness due to the fine size of the nanoparticles.

- The printed parts have high material density and strength.

- The process is relatively clean and safe due to sealed cartridges and the lack of loose powder.

Drop-on-Demand (DOD)

DOD doesn’t work by depositing a continuous stream of photopolymer but it eposites it dropwise when required. It works with two printheads, one print head for build material and ther for supporting material. It is suitable for printing wax patterns and investment casting.

Characteristics

- DOD provides exceptional accuracy and surface finish, with layer thickness as fine as 6 microns and X-Y resolutions around 22 microns.

- It can produce extremely smooth and precise wax models ideal for lost-wax casting.

- Materials Used in Material Jetting

Material Used in Additive Manufacturing Material Jetting

Unlike powder-bed fusion methods like direct metal laser sintering (DMLS), which use metal powders such as stainless steel and titanium, Material Jetting uses photopolymers and waxes. This limits strength but enables fine detail, color printing, and multi-material builds.

Photopolymers

Photopolymers are the most commonly used material from material jetting materials. These are liquid resins that cure rapidly when exposed to ultraviolet light. They can simulate a wide range of properties, from rigid plastics to flexible rubber-like materials, and even transparent or biocompatible options.

Metals and Ceramic

In NanoParticle Jetting (NPJ), metals and ceramics are used in the form of nanoparticles suspended in a liquid carrier. Common materials include stainless steel, titanium, zirconia, and alumina.

Waxes and Specialty Resins

Drop-on-Demand (DOD) systems primarily use wax materials to produce high-precision casting patterns. These waxes melt easily and burn out cleanly which makes them ideal for investment casting in jewelry and dentistry.

Advantages of Material Jetting

Print Resolution and Accuracy

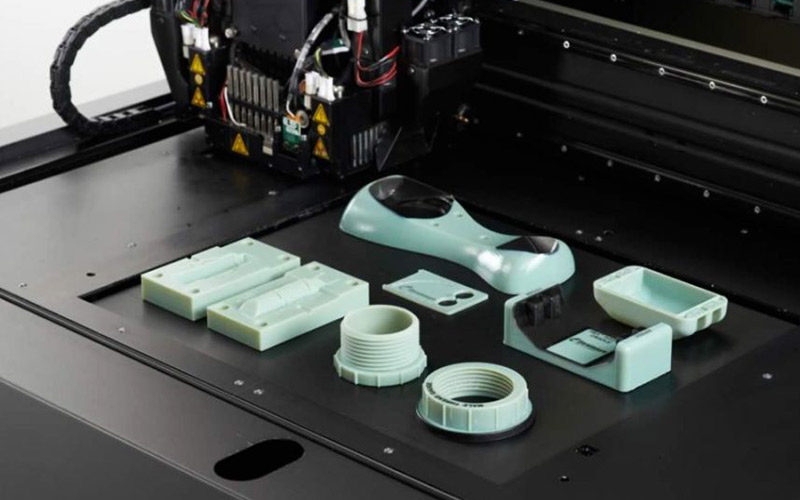

3D printing material jetting provides high resolution as fine as 13–16 micrometers (0.013 – 0.016 mm) resulting in precise detailing of the model. Not only this, the components or model obtained using MJ is detailed and dimensionally consistent.

Surface Finish

The components obtained through MJ have a polished appearance making it ideal for visual and functional prototypes.

Multi-Material Printing

The material-injecting method supports simultaneous printing with multiple materials in one job.

This enables it to blend materials with different mechanical properties, such as:

Rigid and flexible zones in one part.

- Transparent and opaque combinations.

- Varying levels of stiffness or rubber-like textures.

Full-Color Printing

MJ is capable of producing 3d colored models for a realistic approach. This not only makes the model visually appealing but is valued for conceptual understanding.

Homogeneous Material Properties

The components or model obtained with the help of MJ shows uniform thermal and mechanical properties.

Low Material Waste

Since DOD material jetting uses material only on demand, that’s why it doesn’t create much remarkable material wattage.

High-Speed Printing

The MJ process used wide printheads, enabling it to process faster than traditional methods such as FDM.

Disadvantages of Material Jetting

Limited Material Options

- Material Jetting is primarily limited to photopolymers and waxes, restricting its use to a narrow range of applications.

- Metal and high-performance polymers are not supported, making MJ unsuitable for engineering-grade functional parts.

Poor Mechanical Properties

- Printed parts are generally brittle and have low elongation at break, so they are unfit for functional or load-bearing applications.

- Photosensitive materials degrade over time, especially under UV exposure, reducing the long-term reliability of parts.

High Costs

- Material costs are among the highest in 3D printing, often exceeding $1000 per kg.

- MJ machines are expensive to purchase and operate, limiting accessibility for smaller businesses or low-budget projects.

Support Material and Post-Processing Requirements

- MJ frequently requires support structures, increasing material usage and printing time.

- UV post-curing is often necessary to fully harden parts, adding complexity to the workflow.

Applications of Material Jetting

Medical and Healthcare

Due to its high precision and accuracy as well as biocompatibility it is used in the medical and health care department for manufacturing of anatomic models and medical devices such as surgical tools.

Jewelry

Metal jetting also finds its application in creating consistent and intricate jewelry designs as well as for casting. In casting DOD technology prints sharp-edged, tiny features ideal for luxury and artistic pieces.

Engineering

Engineers use this technology to manufacture complex mechanical parts with high accuracy.

Aerospace and Automotive

In Automotive and aerospace lightweight jigs and custom tools are produced faster than traditional machining using MJ. Not only this, dashboards and Interior Prototypes with realistic textures and finishes are manufactured.