The Rockwell hardness test is a widely used method for evaluating material hardness in modern industry. It provides immediate results by measuring the depth of indentation under a standard load, eliminating the need for optical measurement. This simplicity reduces operator error, speeds up production, and supports automated testing. Due to its speed, consistency, and ease of use, Rockwell is a preferred method in hardness testing.

Contents

What is the Rockwell Hardness Test?

The Rockwell Hardness Test was invented by two people, namely Hugh Rockwell and Stanley P. Rockwell, both men were not related but worked for the New Departure Company in Bristol. The idea was to create a test that was more efficient and did not depend so much on the operator like other methods. They first applied for the patent rights to their invention in the year 1914 on July 15, but the approval finally came on February 11, 1919, five years later.

The Rockwell Hardness Test measures the hardness of a material by measuring the depth pierced by the indenter with an applied load. Rockwell, unlike Brinell or Vickers, does not measure the indentation size through visual observation; rather, the machine gives a direct reading.

Rockwell Hardness Test Procedure

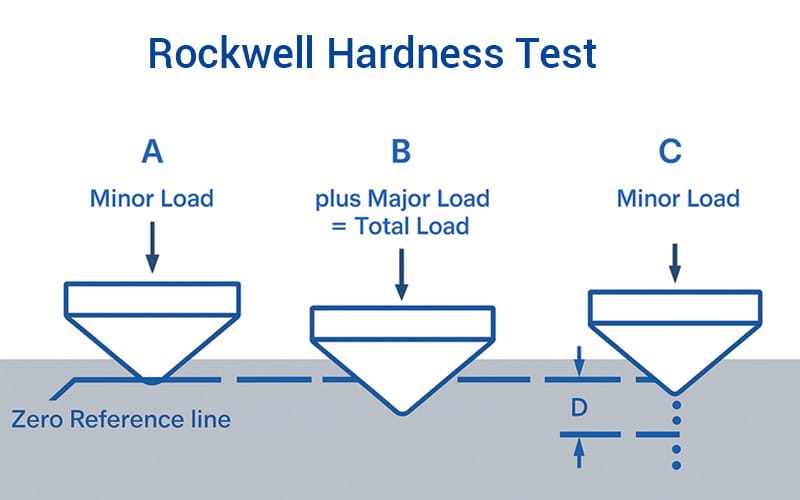

The principle of the Rockwell hardness test method includes the use of a minor and a major load to check the material hardness according to differential depth measurement. It also applies different loads using different indenters, which are known as scales. The scales are denoted by different last letters like HRA, HRB, HRC, and so on, which indicate the different resulting Rockwell Hardness Number (HR) obtained by applying different loads.

Sample Preparation

To prevent the test sample from deforming under the applied load, ensure the surface is smooth, flat, clean, and thick.

Selecting the Correct Scale

Select the scale according to the type of material tested. For example, choose HRB for copper or soft brass, and HRC for hardened steel.

Testing Steps

Apply a minor load of 10 kgf to set a zero reference point using the indenter, then measure the depth of indentation using the dial or digital screen.

Apply the major load (60/100/150 kgf depending on the scale) on the same spot where the minor load was applied.

The next thing is to make a deeper indentation, to do that, the major load is placed for a dwell time of about 2-6 seconds, so the measurement can be taken.

To measure the final indentation, you’ll take off the major load, while leaving the minor load on.

Read the measurements and hardness value directly from the machine.

Rockwell Hardness Testing Machine

The Rockwell hardness testing machine is made up of an indenter system, load application mechanism, and a direct reading interface (either an analog dial or a digital screen). The two primary types of indenters are Steel Ball Indenters for testing softer materials (e.g., HRB scale) and Diamond Cone Indenters (Brale) for harder materials (e.g., HRC scale).

Applications of Rockwell Hardness Test

The Rockwell hardness test is known to be simple and adaptable; because of this, it is commonly used in many applications across different industries:

- Used in Metals and Alloys to evaluate the hardness of steels, copper alloys, aluminum, and more.

- Applied in Manufacturing and Engineering to produce lines for quick quality checks.

- In Automotive and Aerospace to ensure structural components are durable and strong.

- Used for Heat Treatment Verification to confirm the effectiveness of processes like annealing and quenching.

Advantages and Disadvantages of Rockwell Hardness Test

Advantages

- Compared to other testing methods, Rockwell hardness test is faster and saves time because values are read out instantly from the screen.

- This method hardly has errors because the measurements are mainly done automatically and not by human operators

- Measurements are observed with the naked eye; here there is no need for the use of an optical device like a microscope for the procedures.

- It can be used to test a wide range of materials and hardness levels, which makes it a very versatile and scalable testing method.

- The Rockwell hardness test is very cost-effective.

Disadvantages

One major disadvantage of this test is that it is sensitive to how the surface of the test material is, whether contaminated with oil, and if it is rough or curved. These can produce uneven results. Another limitation is that this test method is best for samples with a flat surface; it struggles with complex shapes.

Difference Between Brinell, Rockwell, and Vickers Hardness Tests

The table below provides a comparison of the Brinell, Rockwell, and Vickers hardness tests.

| Feature | Rockwell | Brinell | Vickers |

|---|---|---|---|

| Indenter Type | Steel ball / Diamond | Steel ball | Diamond pyramid |

| Measurement Basis | Depth | Indentation diameter | Indentation diagonal |

| Load Range | 60–150 kgf | 500–3000 kgf | 1–100 kgf |

| Best For | All metals | Coarse materials | Thin and hard materials |

| Precision | Moderate | Low | High |

| Ease of Use | Very high | Moderate | Requires microscope |

| Application Speed | Fast | Slower | Moderate |

| Surface Preparation | Minimal | More critical | Highly critical |

Each material hardness test has its niche; Rockwell is preferred for speed and automation, Brinell for uneven surfaces, and Vickers for microhardness and thin materials.

FAQ

1. How Many Rockwell Hardness Testing Scales Are There?

There are 30 Rockwell hardness scales in total which depend on the material type, and are each denoted by letters like A, B, C, etc. They are grouped into two categories which are the Rockwell Regular Scales and the Superficial Rockwell Scales.

2. What Is The Difference Between Rockwell Regular and Superficial Rockwell Scales?

The Rockwell Regular Scales are used to test thicker materials by applying bigger loads, for example, a minor load of about 10 kgf is applied, with major loads ranging from 50 to 150 kgf. On the other hand, Superficial Rockwell Scales are used to test thinner materials, where the minor load applied is about 3 kgf, with major load ranging from 15 to 45 kgf.