Traditional strip production begins with large ingots or thick slabs that go through several stages such as hot rolling, cold rolling, and annealing. This conventional approach requires massive equipment, consumes a lot of energy, and results in high processing costs and metal losses.

Powder rolling, a powder metallurgy process, offers a more efficient alternative. It uses metal or alloy powder as the starting material, feeding it into a rolling mill to produce thin green strips. These strips are then densified through sintering, followed by rolling and annealing. With fewer steps and lower material waste, powder rolling delivers high-density metal strips with reliable performance and cost savings.

Contents

Evolution of Powder Rolling Technology

In 1843, Henry Bessemer pioneered the use of powder rolling to produce copper strip from copper powder.. After that, people began to study and use the process in different ways. This process is found to be more convenient and economically friendly with lower cost compared to traditional methods such as foreign. In China, research on powder rolling forming started in the 1960s and has continued to develop since then.

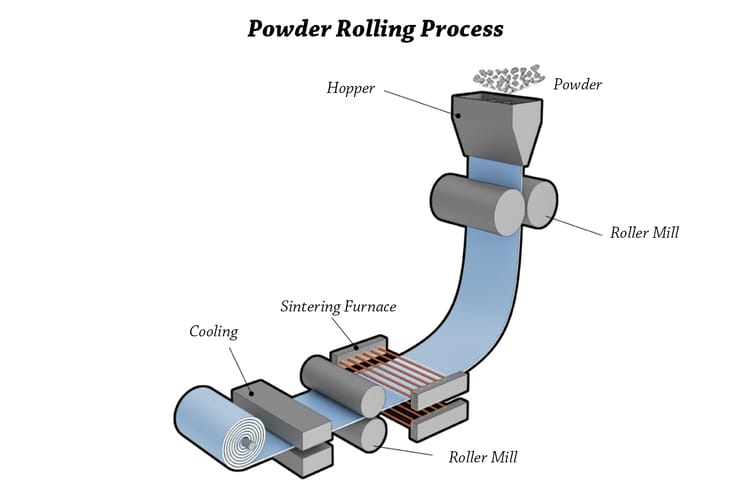

Powder Rolling Process

The powder rolling process is categorized into three types depending upon the rolling direction, including:

- Horizontal Rolling

- Vertical Rolling

- Slop Rolling

Here we will explain the vertical rolling process, which is most common;y used.

Powder Feeding

In the first step of powder rolling, the fine, irregular metal powder is stored in a feed hopper.

This powder then flows downward into the roll gap by gravity.

Powder Entry into Roll Nip

The metal alloy powder enters the roll nip and is drawn in due to gravity and friction between the powder and the roll surface. This friction and gravity combinedly create a pumping action that helps pull the powder through.

Roll Compaction

As the powder passes through the roll gap, it is compacted under high pressure. This is the main step of powder rolling, where loose powder is compressed into a green strip with initial strength and coherence.

Strip Formation

The final stage resembles conventional metal rolling, where compressed powder forms a solid, coherent green strip.

Sintering

The green strip is sintered in a suitable atmosphere such as inert gas or vacuum. This sintering process increases density, strength, and ductility. Not only this but if mixed powder of multiple metals is used, sintering also helps homogenize the structure.

Post Treatment

Finally, after sintering, the strip may undergo additional cold or hot rolling passes. These are performed to reduce thickness, improve density, and refine mechanical properties.

Factors Affecting the Powder Rolling Process

Here are the factors that can affect the efficiency of the powder rolling process in the manufacturing of metal sheets:

Physical Characteristics of Powder

Some of the important properties of powder materials that have a direct impact on sheets and how powder compacts and deforms during the whole process. These properties include:

- Shape of particle

- Size of particle

- The apparent density of powder

- Flow ability

- Hardness

- Powder’s ability to compress.

Roll Speed

Lower roll speeds result in higher green strip density. For example, a roll speed of 0.366 rpm led to a strip density of 90% of cast aluminum, while a higher speed of 0.73 rpm reduced density to 79.6%.

Roll Gap

The roll gap directly affects the density and thickness of the strip. Reducing the gap can produce thinner and denser strips, but if it’s too small, edge cracking may occur. In most cases, the maximum strip thickness is limited to about 1% to 1.5% of the roll diameter.

Sintering Temperature

Sintering temperature has a direct impact on the softness and ductility of strips. For example, increasing the sintering temperature makes the aluminum strip softer and more ductile.

Sintering Time

Sintering duration also plays a role in determining the final microstructure and mechanical properties of the strip.

Applications of Powder Rolling

Multiple Layer Composites

Powder rolling is used to manufacture multilayered metal sheets by the combination of different metal powders. Using such composites for the manufacturing of sheets offers them improved strength, corrosion resistance, and better thermal performance.These sheets are considered ideal for high-stress environments.

Porous Filter

Metal powder rolling is also used in the manufacturing of metal parts with controlled porosity, which are useful for filtering gases or liquids in various industries. Such as

- Sintered Bronze Plates: These are usually used in lubrication systems.

- Porous Metal Sheets: These are used in air or fluid filtration systems.

Electronics and Electrical Products

Thin metal sheets made through powder rolling are used in many electronic devices and electrical systems, such as in connectors.

Titanium-Based Materials

DPR is also used to make thin sheets and plates of titanium and its alloys. These sheets are highly resistant to corrosion and made to work under harsh conditions. As a result, these sheets are considered essential for manufacturing military jets, high-end cars, and other advanced vehicles.

Advantages of Powder Rolling

Lower Capital Investment

One of the remarkable advantages of powder rolling is it requires less equipment cost compared to conventional methods like melting and forging.

High Flexibility and Versatility

Powder rolling process supports multilayer sheet production such as Ti-6Al-4V/TiAl/Ti-6Al-4V and enables rapid prototyping.

Simplified Process Flow

Powder rolling is a simple process and includes fewer processing stages than traditional techniques.

Cost-Effective Raw Materials

It utilizes affordable powders, reducing overall production costs.

Precise Composition Control

Another factor that makes this process attractive is that it allows accurate tailoring of alloy content and the use of ultra-pure metals.

Limitations of the Powder Rolling Process

Fragile strip ends

One of the limitations of Powder rolling is its strip ends are often weak and can break easily.

Uneven density

In powder rolling, the strips or sheet forms may not have the same density throughout, affecting strength and quality.

Large rolls needed for thin strips

To make very thin strips, bigger rolls are required, which increases equipment size and cost.

BLUE is your trusted powder metallurgy supplier, certified to ISO 9001:2015 and backed by 20 years of expertise. We supply high-quality porous sintered metal plates with sizes up to 330 × 1000 mm. Single-layer thickness ranges from 0.5 to 3 mm, while multi-layer options reach up to 20 mm.