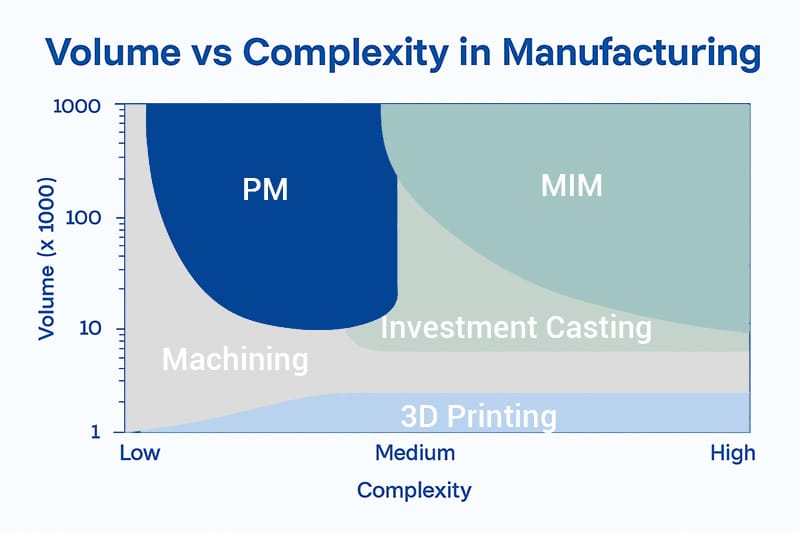

Metal Injection Molding (MIM) and conventional Powder Metallurgy (PM) both transform metal powder into high-precision, near-net-shape parts through sintering. Their forming routes, however, diverge sharply, leading to different feasible geometries, part sizes, and end-use applications.

Contents

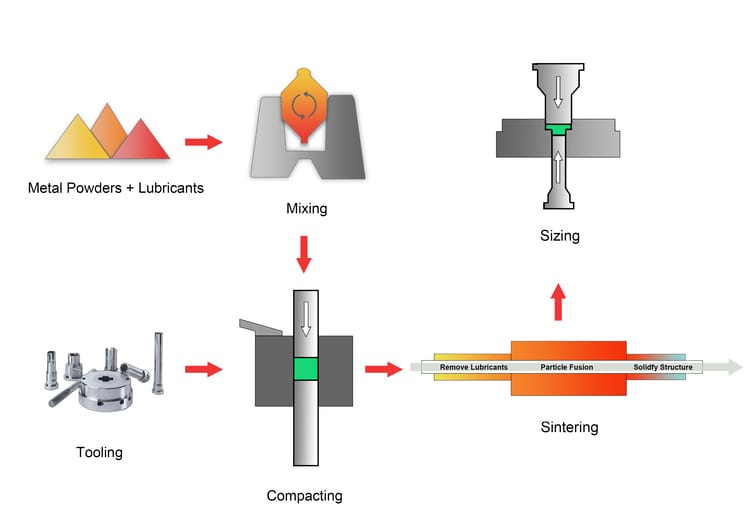

Powder Metallurgy Basics

Powder metallurgy process is widely used for producing metal components from ferrous and non-ferrous powders, especially in high-volume manufacturing of precision parts.

1. The powder metallurgy process begins by blending the metal powder with some suitable binder depending on the required properties of the components.

2. This mixture is then converted into a green part with the help of compaction. The compaction can be done by:

- Cold die compaction,

- Hot compaction

- Iso-static pressing

3. Finally, this green part undergoes sintering, and particles bind with each other, producing a high-strength metal component.

Then the sintered component may be subjected to post-treatment such as heating, polishing or machining to obtain the desired properties.

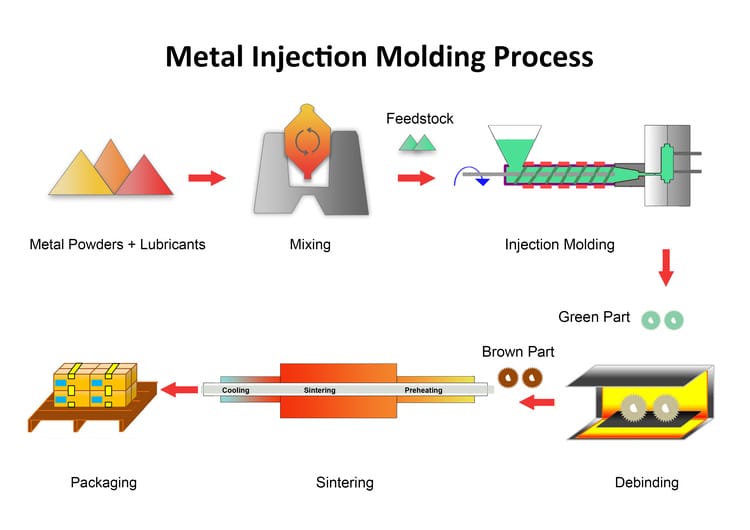

Metal Injection Molding Basics

Metal Injection molding is a manufacturing process but developed by combining the PM and plastic injection molding. The process enables you to produce cost effective compact, and complex design metal components.

Feedstock Preparation

Fine metal powder (≤ 20 µm) is blended with wax-polymer binder until it flows like plastic. Stable viscosity supports quality control down the line.

Injection Molding

The feedstock is heated to roughly 120–200 °C, injected under high pressure into a steel mold, then cooled. The green part already matches the final shape within tight tolerances.

Debinding

Debinding pROCESSremoves the binder from the green part in two steps: solvent or catalytic treatment dissolves waxes to open pores, followed by thermal heating to burn off the remaining polymer. This produces a “brown part” ready for sintering.

Sintering

In vacuum or inert gas at about 1 300 °C, the brown body shrinks 15–20 % and reaches 96–99 % of theoretical density, yielding a strong, near-net-shape component that usually needs minimal finishing.

Metal Injection Molding vs. Powder Metallurgy: A Quick Comparison

The following is a detailed comparison between Metal Injection Molding and Powder Metallurgy.

Material Properties

Here is a comparison table between the properties of material in PM and MIM

| Property | Powder Metallurgy | Metal Injection Molding |

|---|---|---|

| Powder Particle Size | Coarse (50–150 µm) | Fine (<20 µm) |

| Particle Shape | Irregular to spheroidal | Slightly non-spherical; aspect ratio 1.2 to 1.5 |

| Tap Density | Lower due to coarser particles | At least 50% of theoretical density |

| Feedstock Composition | Pure or alloyed powder | Small lubricant, Metal powder, and thermoplastic binder system |

| Material Cost | Lower | Higher due to powder size and binder requirements |

| Material Purity | Moderate | Higher purity, suitable for demanding applications |

| Packing Density Preference | Moderate; depends on particle shape | Near-spherical powders preferred for better packing and flow |

Design Flexibility and Innovation

Powder metallurgy forms parts through high-pressure uniaxial compaction, which works well for simple shapes. MIM, on the other hand, uses a flowable feedstock and injection molding to produce complex designs with high precision and fine surface finishes.

Structural Uniformity

In powder metallurgy, the compaction of components is done along a single axis, which results in uneven distribution of friction and tensile strength. As a result, they develop inconsistent density in the components. Whereas in MIM, the feedstock is injected into a mould, and then a uniform pressure is applied, which results in uniform packing and consistent structural properties.

Densification

MIM offers better particle densification thanks to finer powders and more uniform packing during sintering. As a result, MIM parts typically reach densities of 95% to 99%, while PM parts usually fall between 85% and 93%, with higher porosity.

Mechanical Properties

Since MIM exhibits better flow and higher density, that’s why it has superior mechanical properties than PM; not only this, the components made with metal injection moulding have high strength, better elongation and better fatigue resistance.

Surface Properties

MIM exhibits a smoother surface finish, which not only enhances appearance but also functional properties. This is because of the finer powder used compared to PM. MIM shows a surface roughness as fine as Ra 1 µm which means its surface does not require additional finishing process like PM. Components obtained in PM show rough surface with a Ra of about 1.6-3.21 µm which indicates that surface of components requires polishing or other surface finishing treatment.

Corrosion Resistance and Durability

The improved density and reduced porosity of MIM components not only enhance strength but also increase corrosion resistance. This makes MIM parts more suitable for demanding environments or applications where long-term durability and chemical resistance are essential.

Applications and Industry

MIM Applications

- Medical Devices

Since the components obtained through MIM offer high precision and biocompatibility. As a result it is widely used in manufacturing medical instruments such as medical implants and surgical instruments.

- Consumer Electronics

MIM is a considerably preferred process for producing small, highly detailed components such as phone connectors, housings, and hinge components.

- Automotive

Both MIM and PM are used extensively in the automotive industry. Metal injection moulding is preferred for small, intricate parts such as fuel injector components, actuators, and locking systems.

- Aerospace

In aerospace, MIM is utilized to produce lightweight components and require excellent strength-to-weight ratios and precise geometries. Components like spray nozzles, locking mechanisms, and fittings are often made through MIM.

PM Applications

- Automotive

Powder metallurgy finds its application in automotives for producing larger or simpler components such as gears, bushings, sprockets, and structural brackets.

- Aerospace

PM is used for simpler structural parts in aerospace, where extreme precision is not critical. Parts like brackets or reinforcement elements are manufactured using powder metallurgy.

- Power Tool

PM plays a major role in the production of industrial components like bearings, filters, and structural inserts.

- Home Hardware

Powder metallurgy is a cost effective way to manufacture home hardware devices such as handles, hinges, and fasteners.

- Home Appliances

Powder metallurgy is extensively used for producing components for home appliances such as for washing machines, for locks and for lightning systems.

Cost and Production Considerations

When it comes to the cost of both methods it depends upon various factors such as raw material, equipment and the need to finish the process.

- In the case of injection molding metals, the fine metal powder is used in combination with a binder, which increases its cost compared to PM.

- Not only this the equipment or machine of MIM is also costly compared to traditional powder metallurgy.

- The only factor that reduces the overall cost for MIM is its surface finishing. It produces components with excellent surface finishing with minimum or no need for a secondary finishing process.

In short, MIM is cost-effective for producing small, complex parts in large volumes, while PM is more suitable for mass-producing simple parts with tight tolerances.

How to Choose Between MIM and PM

Here is a quick summarization which can help you choose between MIM and PM.

| Attribute | MIM | PM |

|---|---|---|

| Part Complexity | Complex, intricate shapes with fine features | Simple, axial shapes |

| High Mechanical Properties | Required high strength, toughness, and corrosion resistance | Moderate mechanical properties are required |

| Surface Finish is Critical | Smooth surface | Rougher finish is acceptable or secondary finishing is planned |

| Tighter Tolerances Needed | Moderate tolerances | Tight tolerances acceptable |

We are a trusted manufacturer specializing in powder metallurgy and metal injection molding with 20 years of experience. We supply standard parts with no tooling fees and offer customized solutions to meet your specific needs.