Tumbling is a surface finishing method that removes burrs, smooths metal parts, and creates a uniform finish. The tumbling process is usually performed using centrifugal barrel finishing (CBF) for large batches of metals. The most remarkable thing that makes tumbling superior to grinding and polishing is that it is Ideal for high-volume batches as well, and it offers high uniformity across parts.

Contents

What Is the Tumbling Process?

Tumbling process deburrs and polishes parts by spinning or vibrating them with abrasive media and water, then rinsing, drying, and inspecting the finished pieces.

Choosing the Media and Compound

In this step, the abrasive media is selected, either ceramic, steel or plastic, and a small amount of water or water-based soap is added. The addition of water helps lubricate the metal parts, reducing friction, and it also acts as a cleaner for any further dirt or oil.

Filling the Tumbler

Here, the material is loaded into the tumbler so that the barrel is about 75–90 % full. If the barrel is not filled properly, the process will not be able to give the desired results.

Setting Machine Parameter

The parameter for the tumbling machine is set depending on its type, either a rotating tumbling machine or a vibrating tumbling machine. For a rotating tumbling machine, its rotation is set to about 30 to 60 RPM, whereas for vibratory units, select around 1,500–3,000 vibrations per minute.

Running the Machine

Finally, the material is tumbled for about 10 minutes up to 2 hours, knocking off heavy burrs and flash; harder steels need longer, and softer metals need less time. After the rough cut, the media is swapped out, and further tumbling machines process for 1–4 hours to smooth and polish every surface gently. The exact time depends on how glossy you want the final finish.

Separate, Rinse, and Inspect

When a desired polished look of metal is obtained, it is dumped into a screen or separator to free the parts from the media. The material is then rinsed under running water to wash away any leftover abrasive or soap. The parts are dried with warm air or a vacuum dryer and then checked for smoothness and correct dimensions.

Metals Suitable for Tumbling Process

Here are some common metals that can be tumbled in the tumbling process to get a smoother, resistance-free finish:

- Plastic

- Aluminum

- Brass

- Copper

- Stainless Steel

- Silver

Wet Vs Dry Tumbling

Below is a detailed comparison of wet tumbling and dry tumbling.

| Features | Wet Tumbling | Dry Tumbling |

|---|---|---|

| Medium Used | Water with abrasive or polishing compound | Dry media like corn cob, walnut shell, or ceramic |

| Finish Quality | Smoother, shinier finish | Softer, matte or satin finish |

| Dust Generation | Minimal (water suppresses dust) | High (generates dust from media and metal) |

| Cleaning Requirement | Requires thorough rinsing and drying after tumbling | Minimal cleaning – parts usually come out clean |

| Noise Level | Quieter (due to water cushioning) | Louder |

| Cycle Time | Often shorter due to aggressive action | Longer – better for gentle polishing |

| Best For | Heavy cleaning, deburring, polishing | Light polishing, burnishing, finishing touches |

| Media Wear | Media wears faster due to water abrasion | Media lasts longer |

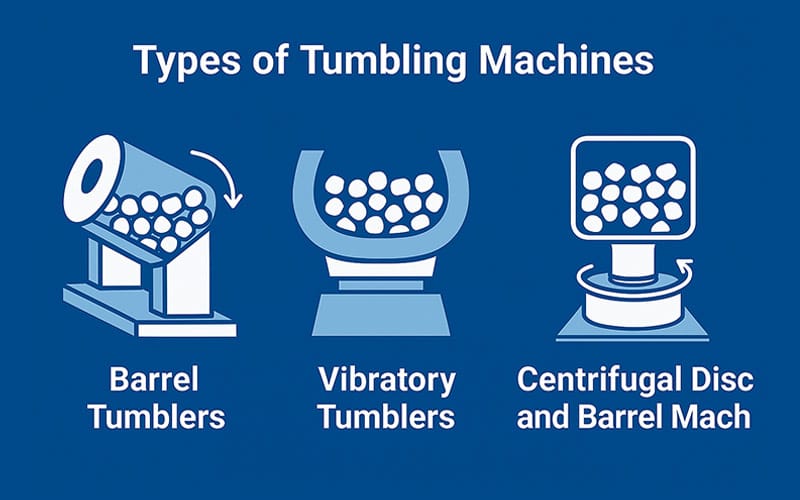

Types of Tumbling Machines

Barrel Tumblers

The barrel tumbling process is considered one of the traditional tumbling methods. Here, the troubling machine consists of a rotating drum or barrel in which material is added. When the barrels turn, the metal components tumble over each other. As a result, burrs are removed from the metal surface. This machine is used for deburring, polishing, and surface smoothing, especially for harder metals. However, these machines tend to have longer cycle times compared to other types and are noisier.

Vibratory Tumblers

These tumblers usually consist of a large doughnut-shaped drum that vibrates at high speed. When the drum vibrated, the metal particles scrubbed against each other, leading to the removal of burrs. These machines are used for precision tumbling of delicate parts, such as jewelry. Vibratory tumbling is considered superior to barrel tumbling due to its efficient, uniform finish and shorter processing time.

Centrifugal Disc and Barrel Machines

Centrifugal tumblers, whether disc or barrel type, are used at high-speed rotation to create powerful forces to enhance the tumbling process. Compared to traditional machines, these are much faster and can handle both delicate and tough parts effectively. They are often used in industrial settings for fine polishing, aggressive deburring, and achieving high-precision finishes in a short time.

Tumbling Media and Compounds

Tumbling media are the materials placed in the tumbler along with the workpieces to assist in the finishing process. The common types of tumbling media include:

Ceramic Media

Ceramic media is considered durable and aggressive, which is ideal for deburring and shaping hard materials like iron, steel, etc.

Plastic Media

Plastic media is usually made of polyester or urea resins, which are mixed with abrasives like aluminium oxide. This media is specifically used for deburring, smoothing, and light finishing of soft metals such as aluminium, brass and copper. It comes in various shapes and sizes, such as cones, triangles and pyramids, to reach different contours without damaging surfaces.

Steel Media

Steel media, which typically consists of carbon steel or stainless steel, is used mostly in wet tumbling with a burnishing compound. This media is suitable for burnishing and producing a bright, polished finish for copper, brass, silver, and gold.

Organic Media

Organic media is used for dry polishing and tarnish removal of soft metals, such as copper and bronze. It usually consists of walnut shell grit, corn cob, and wood pegs and is mostly used in dry tumbling. It offers gentle cleaning and polishing without damaging the delicate surface of sifting metals.

Tumbling Compounds

These are the compounds added during tumbling process to enhance the action of media. Here are the common compounds:

- Cleaning Compounds: These compounds are used to remove grease, oil, and dirt from parts.Polishing Compounds: These compounds help achieve a high-gloss finish on metals.Rust

- Inhibitors: Sometimes rust inhibitors are also added while tumbling to prevent corrosion during and after the tumbler process.

- Burnishing Compounds: These compounds work with steel media to create a mirror-like shine.

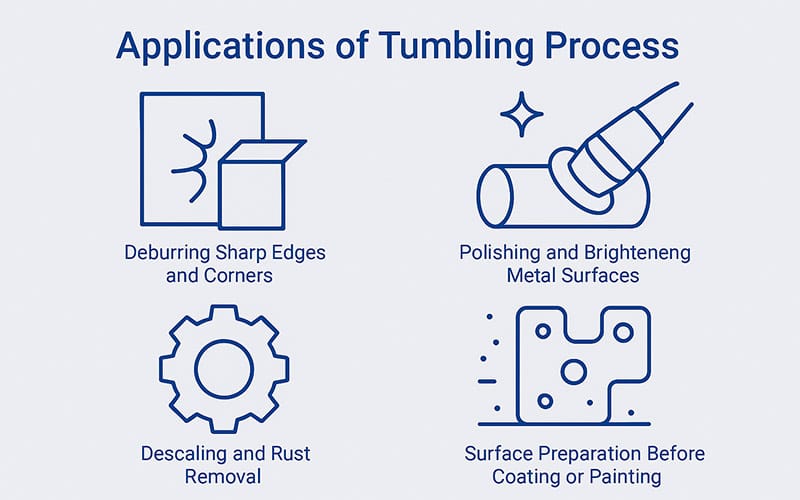

Applications of Tumbling Process

Deburring Sharp Edges and Corners

Tumbling is one of the most effective ways to remove the sharp edges, burrs and machining marks from metal parts. When tumbling media and workpiece get in contact, mechanical abrasion occurs, leading to a smooth finish. The tumbling process is used to remove burrs from machined parts such as powdered metal pcomponents and castings.

Polishing and Brightening Metal Surfaces

The fine abrasive and burnishing action in tumbling is responsible for the polished bright finish of metals such as brass, copper or stainless steel. To make the surface smoother, it is used in jewelry finishing, automotive trim, plumbing and decorative hardware.

Descaling and Rust Removal

When hard media with a rust removal compound is utilized in tumbling process, it leads to abrasively removing surface oxides, mill scale, or light rust from metal parts. Such tumbling is used in the metal stamping and fabrication process.

Surface Preparation Before Coating or Painting

Tumbling is used to create a uniform and smooth surface, which improves coating adhesion. Coating adhesion is improved due to an increase in surface area and removing contaminants like oils, oxides, and mill scale from metal surfaces. As a result, tumbling found its application in powder coating, electroplating.

Advantages of the Tumbling Process

Cost-effective for Bulk Processing

Tumbling process is considered ideal for simultaneously processing large quantities of small to medium-sized parts. It can process hundreds of metal parts in one cycle with minimal human involvement. This significantly lowers the cost per part finishing.

Uniform and Consistent Finish

Since there is constant and repeated contact between tumbling media and metal components, it results in a consistent surface finish across all parts.

Automated and Scalable

One of the remarkable advantages of the tumbling process is that its machines are easily automated. This process is scalable, from benchtop units for prototypes to industrial machines for mass production.

Limitations of the Tumbling Process

Intricate or Fragile Parts

Tumbling process may not be ideal for intricate or fragile parts. It can lead to small holes as well as sharp edges, thin walls, or delicate features that may be damaged due to continuous media impact.

Longer Processing Time

Tumbling can take several hours to achieve the desired surface finish compared to manual or specialized finishing methods.

Limited Control Over Specific Surface Features

Since tumbling process is a bulk process, it cannot be treated selectively in certain areas. It applies the same abrasive action across all surfaces, which may not be suitable for parts requiring precision surface finishes.