Soft Magnetic Composite (SMC) is a magnetic material made by pressing insulating iron powder into a shape and then heat treating it. SMC components are particularly valued for their ability to support innovative designs in motors and inductive solutions compared to traditional laminated technologies. The magnetic properties and high electrical resistivity make the SMCs superior to other sintered materials. These are considered ideal for building low-loss parts, especially at high frequency for next-generation electric and hybrid vehicles.

Contents

What is Soft Magnetic Composite?

SMCs are basically isotropic materials that consist of ferromagnetic powder particles covered with an insulated material such as epoxy or polymer. This unique structure allows for excellent magnetic performance while minimizing eddy current losses, especially at high frequencies. Mostly, SMC materials are considered ideal for constructing compact and complex geometrical components such as electric machines, transformers, and inductive devices.

Soft magnetic composites are manufactured using powder metallurgy combined with new techniques, such as warm compaction, two-step compaction, multistep and magnetic annealing. The final components undergo heat treatment at relatively low temperatures while optimizing magnetic performance.

Types of Soft Magnetic Composites

SMCs are available in a variety of formulations to suit different magnetic and mechanical performance requirements. Common categories of Soft magnetic composites include:

Pure Iron

These are the most basic and mostly used soft magnetic materials. Pure iron SMCs show high magnetic permeability, low coercivity, excellent magnetic performance and minimal energy loss. These properties make them ideal for electromagnetic components like solenoids, actuators, and inductors.

Iron-Phosphorus Alloy

Iron Phosphorus alloys are better than pure iron in coercivity and magnetic permeability. And the addition of phosphorus can increase the impedance value of pure iron, improve the microstructure, promote DC magnetism and prevent magnetic aging.

Iron-Silicon Alloy

Iron silicon based SMC has the characteristics of high magnetic permeability, low coercivity and high resistivity.

Iron-Cobalt Alloy

These SMCs offer high magnetic saturation and low core loss. These are considered ideal for manufacturing components that are compact and lightweight, such as electric motors and generators.

Iron-Nickel Alloy

The high magnetic permeability and low coercivity of iron-nickel alloy are the best among soft magnetic materials. Therefore, it is suitable for electronic applications such as transformers, relays, reactors, and magnetic field amplifiers.

Ferritic Stainless Steel

These soft magnetic composites not only show soft magnetic properties but are highly resistant to corrosion as well. These are utilized for manufacturing components where corrosion resistance is required, such as magnetic cores for transformers, electromagnetic devices, and inductors.

Properties of Soft Magnetic Composite

Here is a technical insight into the key properties of smc soft magnetic composites, focusing on the underlying mechanisms and implications for engineering applications:

High Magnetic Permeability

Since SMCs are primarily composed of ferromagnetic particles like pure iron or FeSi alloys; that is why they exhibit high initial permeability. This property makes them suitable for applications where high-frequency performance is prioritized.

Low Eddy Current Losses

Usually, eddy current loss increases with frequency and material thickness but in SMCs, mitigate this by effectively breaking the eddy current paths through insulating particles. This makes soft magnetic composite material superior to laminated steels.

Isotropic Magnetic Properties

The compact 3D magnetic circuit designs of SMCs allow multidirectional flux paths, which is considered beneficial in axial flux and transverse flux machines.

High Electrical Resistivity

The non-magnetic coatings on core particles in SMCs enhance their electrical resistivity upto 100 to 9,000 micro-ohm-meters (μΩm). This resistivity prevents the short circuit between the particles, leading to a reduced eddy current loss as well.

Good Thermal Stability

SMCs have good thermal stability due to the high curie temperature of their base metal particle, such as iron. It shows the ability to retain magnetic properties up to 770 °C. However, the mechanical integrity of the insulating layer can degrade at elevated temperatures. This can limit their practical use in high-temperature environments.

Low Core Loss at High Frequency

Core loss in magnetic materials consists of hysteresis loss and eddy current loss. SMCs excel at minimizing eddy current losses due to high resistivity. At frequencies above 1 kHz, SMCs outperform laminated steels in total core loss. This makes them ideal for modern high-speed motors and power electronics.

Shape Flexibility

SMCs are formed through powder metallurgy, which allows the creation of 3D geometries such as toroids, claws, and back irons. This eliminates the need for traditional laminations and stacking. As a result, the complexities of assembling are reduced as well as space efficiency in electromechanical devices improves.

Applications of Soft Magnetic Composite

SMCs, with their exceptional properties, offer a wide range of applications in multiple sectors. Here are some of their applications:

Automotive Industry:

Since the Automotive industry is shifting toward electrical vehicles, for this, they need lightweight, compact and high-performance components. SMCs make it possible they be used in the manufacturing of :

- Traction Motors: SMCs are efficient and cost-effective alternatives for manufacturing these motors that eliminate the need for rare earth magnets in traditional motors.

- Axial Flux and Radial Flux Motors: These have Compact motor designs with high torque density.

- Electric Pumps (E-pumps): Used in thermal management and lubrication systems.

- Compressors: Lightweight and efficient, supporting HVAC systems in EVs are manufactured using SMCs.

Industrial Applications

SMCs are also valuable in industrial systems where performance, reliability, and sustainability are essential. These are used in the manufacturing of:

- Motors and Drives: These motors offer low power energy losses and better performance

- Solenoids and Actuators: Solenoids made from SMCs have Improved control precision and response time.

- Fans and Pumps: Such pumps offer more efficient and quieter operation in commercial and industrial environments.

- Valve Controls and Generators with enhanced magnetic efficiency and durability.

Energy Sector Applications

SMCs also found Wide application in the energy sector. Here are the components made from SMCs;

- Wind Turbine Generators with light, efficient generator cores.

- Solar Inverters with high-frequency inductors and transformers.

Manufacturing of Soft Magnetic Composite

Soft Magnetic Composites are produced using advanced powder metallurgy techniques. Here are the steps involved in their manufacturing:

Insulation treatment

First of all, the base material, which is typically iron or an iron-based pre-alloyed powder containing Si, Ni, Al or Co, is automated into spherical particles. After atomization the particles are then coated with an electrically insulating layer, usually a phosphate or silica-based compound.

Mixing and Blending

In the next step, the coated magnetic powders are blended with lubricants or binders to enhance compaction. In this step enhanced mechanical strength additives are also added.

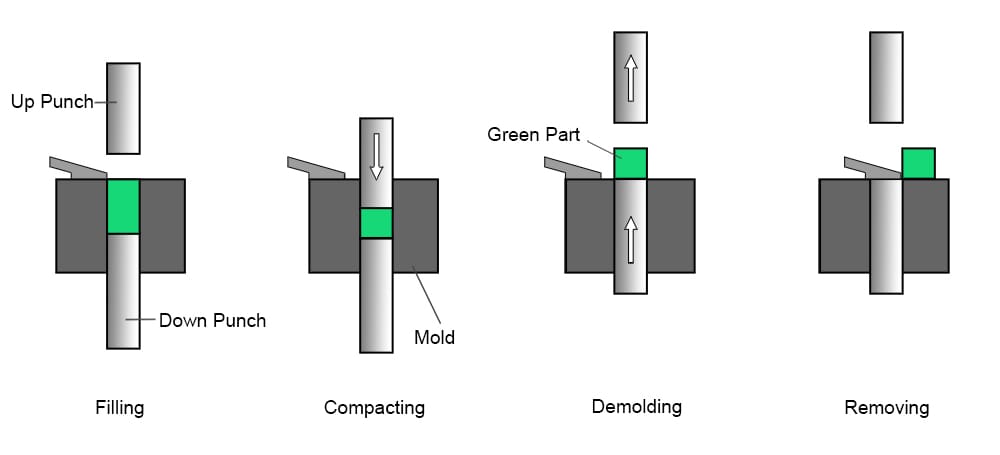

Compaction

The forming methods for soft magnetic materials include cold pressing, warm pressing, and hot pressing. Cold pressing is the most widely used technique, where the powder mixture is compacted in powder metallurgy mold at room temperature under high pressure.

Heat Treatment (Curing or Annealing)

Finally, after compaction, parts are heat-treated or cured, depending on the binder system:

- Curing is used if a polymer binder is involved.

- Annealing may be applied to relieve internal stresses and improve magnetic performance.

After the soft magnetic composite material is pressed, the internal stress increases, pinning points will be generated, the movement of magnetic domains will be hindered, the magnetic permeability will be reduced, and the coercive force will increase, resulting in increased hysteresis loss. Heat treatment can effectively eliminate internal stress and improve the mechanical properties of the material.

Limitations of Soft Magnetic Composite

- Lower magnetic saturation: SMCs typically have lower magnetic saturation levels than traditional laminated electrical steels. This limits their use in high-power density applications.

- Binder limitations: The insulating material or binder used in SMCs can degrade at high temperatures. This restricts their use in high-temperature environments.

- Recycling challenges: Unlike conventional steel, recycling SMCs is more complex due to the composite structure of metal and insulating material.

FAQ

1. Why are Soft Magnetic Composites good at High Frequencies?

The electrically insulating coatings on each particle of SMCs result in reduced eddy current losses. This makes them ideal for high-frequency applications where traditional materials would overheat.

2. Why do Soft Magnetic Composites have Less Hysteresis?

The uniform structure and reduced internal stress of SMCs lower their magnetic domain friction.

This results in narrower hysteresis loops and reduced energy loss per cycle.