China Oil Pump Gear Manufacturer | BLUE

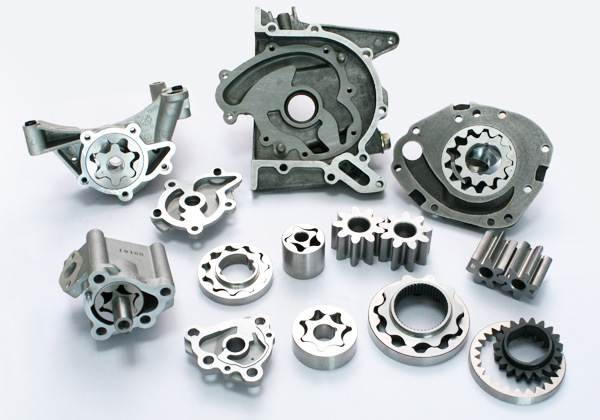

BLUE offers a wide range of oil pump gears that cover nearly all automotive and motorcycle engine models. We have standard oil pump gears and oil pump rotors in stock for direct purchase.

Why Choose BLUE?

BLUE is your reliable supplier of high-quality oil pump rotors, offering free mold design, fast delivery, and a competitive price from China.

BLUE Quality Standards

BLUE assures your product quality with ISO 9001:2015 certified quality management system. We provide a one-year warranty on your oil pump gears.

Standard Oil Pump Gear Shop

We have a wide range of standard oil pump gears in stock for quick delivery. All of these standard oil pump gears come with no mold fees.

Download Oil Pump Gear List

Discover BLUE’s full range of powder metallurgy standard oil pump gears. Download our free product list to find the exact match for your requirements.

BLUE Standard Oil Pump Gears

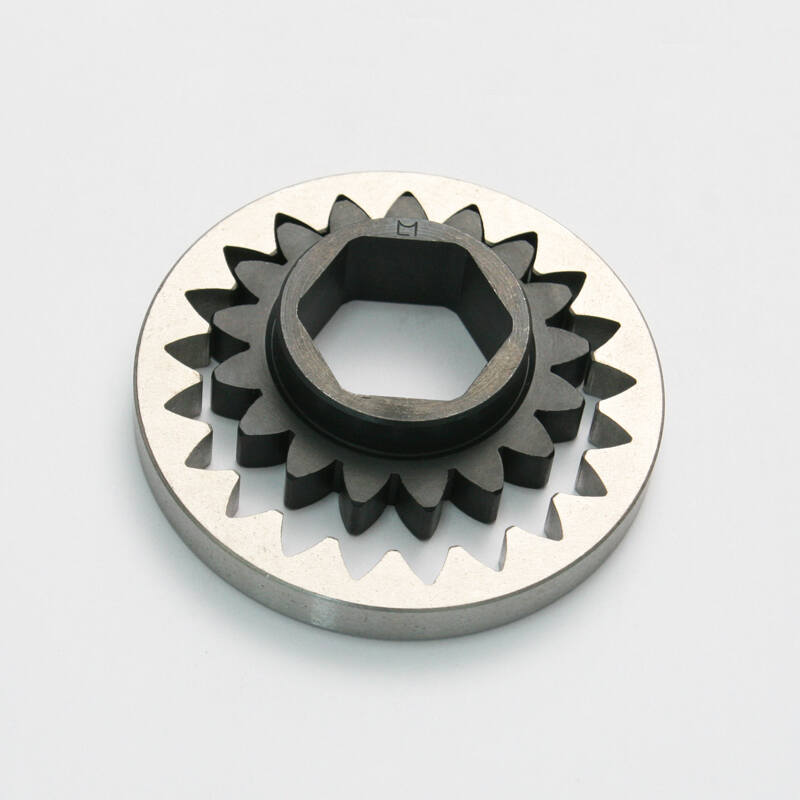

Here are some of our sintered standard oil pump gears. These standard parts do not require tooling fees and are available in stock.

Powder Metallurgy Oil Pump Gear

Powder metallurgy oil pump gears have the advantages of near net shape, less material waste, tight tolerances, etc.

Oil Pump Drive Gear

Oil pump driven gears are made of FC-0208, with the surface heat-treated to a hardness of HRB 65-90, suitable for AUDI.

22RE Oil Pump Gear

22RE oil pump gear is manufactured using powder metallurgy, a green and economical process for mass production.

2ZZ Oil Pump Gear

2ZZ Oil Pump Gear from BLUE is outstanding through our strict quality management system, suitable for 2ZZ engine.

H22 Oil Pump Gear

H22 oil pump gear has excellent strength, hardness and wear resistance to ensure the reliable operation of Honda H22 engine.

5.0 Oil Pump Gear

5.0 Oil Pump Gear is made of high quality metal powder, with a dimensional tolerance within ±0.01mm.

4.6 Billet Oil Pump Gear

BLUE's 4.6 Billet oil pump gear has high consistency in quality across batches, ensuring stable operation of the engine oil pump.

GT350 Oil Pump Gear

BLUE's GT350 oil pump gear is formed by pressing once, with precise tooth shape and no need for secondary machining.

F150 5.0 Oil Pump Gear

F150 5.0 oil pump gear is made of FC-O2O8 pressed and sintered, with excellent quality to ensure the supply of oil in the engine

What is an Oil Pump Gear?

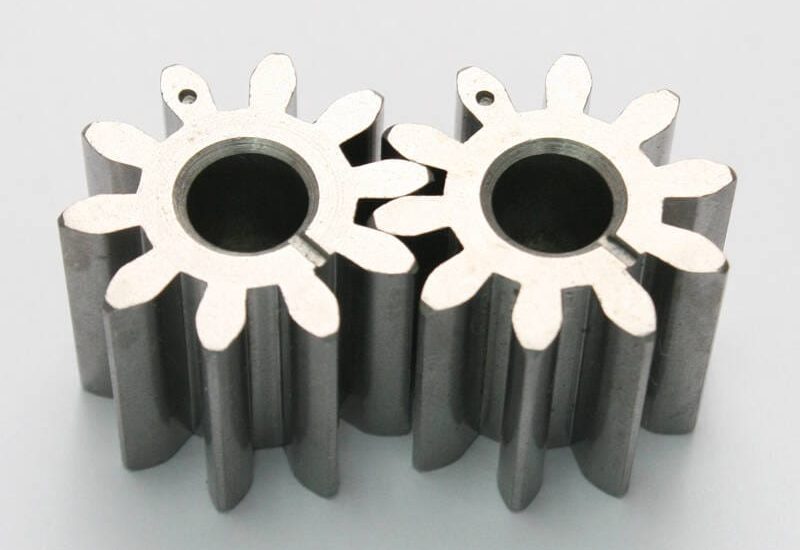

An oil pump gear is a component inside an engine’s lubrication system. It drives the oil pump and helps circulate engine oil through the bearings, pistons, camshaft, and other moving parts. By maintaining oil flow and pressure, the gear ensures proper lubrication and cooling during engine operation.

Oil pump gears typically work in pairs, such as inner and outer rotors in a gerotor pump or two spur gears in a gear-type pump. As the gears rotate, they create suction that draws oil from the sump and then pressurizes it before sending it through the engine’s oil passages. The geometry and fit of the gears directly affect pumping efficiency, pressure stability, and noise level.

These gears are commonly made from materials like alloy steel or P/M iron because they must withstand continuous load, wear, and thermal cycling. Precision and durability are important, as poor gear performance can lead to low oil pressure, increased friction, or engine damage.

BLUE Quality Management System

BLUE produces oil pump gears under the strict supervision of ISO 9001:2015 and IATF 16949:2016 quality control systems.

We conduct a full range of tests, including dimensional and positional tolerances, hardness, tensile, and fatigue strength, to assure that your oil pump gears meet high standards and specifications.

BLUE uses blister trays and more than three layers of cartons to securely package your products, ensuring that all oil pump gears are delivered safely and intact.

These quality control measures ensure that each oil pump gear delivered to you has high precision, hardness, strength, and wear resistance, allowing the oil pump to perform at its best.

BLUE's Oil Pump Gear Advantages

1. All oil pump gears are manually deburred.

2. A variety of surface treatment processes are available, achieving a surface finish of up to Ra 0.6 μm.

3. All oil pump gear tolerances are maintained at ±0.01 mm.

4. Each pair of oil pump gears is matched and measured.

5. Our oil pump gear manufacturing process is strictly controlled, and the quality of different batches of products is highly consistent.

Standard Oil Pump Gear

You might know that powder metallurgy molds are costly. BLUE has a series of standard powder metallurgy parts, which can eliminate mold manufacturing costs and improve production efficiency.

Our oil pump rotors cover applications in cars, motorcycles, scooters, serving FORD, AUDI, PEUGEOT, BENZ, GM, VW, PERKINS, VOLVO, LANDROVER, RENAULT, etc.

We have a variety of standard oil pump gear models for you to choose directly. Free download our oil pump gears product list!

How Oil Pump Gear Works?

The working principle of a gear oil pump relies on the meshing of gears to transport oil.

The working space is defined by the grooves between the pump body, side cover, and gears, which is divided into a “suction chamber” and a “discharge chamber” by the meshing area.

As the gears rotate, the teeth in the suction chamber disengage, increasing the volume and creating a pressure drop that draws in oil.

The oil is then carried to the discharge chamber, where the meshing gears reduce the volume, forcing the oil out.

FAQ's

Here are some of the questions we get asked often. If yours isn’t answered, don’t hesitate to contact us, we’re happy to help!

Rotor Oil Pump:

The rotor oil pump operates using two synchronized rotors—an inner and an outer rotor—that rotate in opposite directions. As they rotate, a vacuum is generated at the inlet, which draws the required liquid into the pump.

Gear Oil Pump:

The gear oil pump works by using a pair of parallel gears inside the pump housing. When these gears rotate, a negative pressure is created on the suction side, which draws liquid into the pump. As more liquid is drawn in, pressure builds up on the discharge side, forcing the liquid out of the pump.