Oil Pump Rotor Manufacturer

BLUE oil pump rotor offer good surface finish, tight dimensional accuracy and great postional tolerance to bring out the best performance of your engine exchange. We offer over 100 standard oil pump rotors and gears with no mold fees for you to choose from.

Oil Pump Rotors Shop in China

Oil pump rotors from BLUE are high quality and high precision, which can reduce noise, reduce friction loss and improve the working efficiency of the oil pump. You can purchase our oil pump rotors directly from our shop.

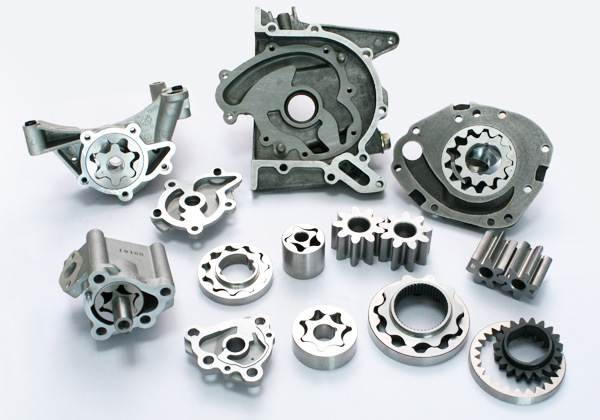

Powder Metallurgy Oil Pump Rotor

Oil pump rotors from China are of high quality and have served in developed countries in Europe and America for many years.

Oil Pump Inner Rotor

The oil pump inner rotors rotate with the outer gear to deliver the oil in the oil pump to the engine, ensuring smooth operation.

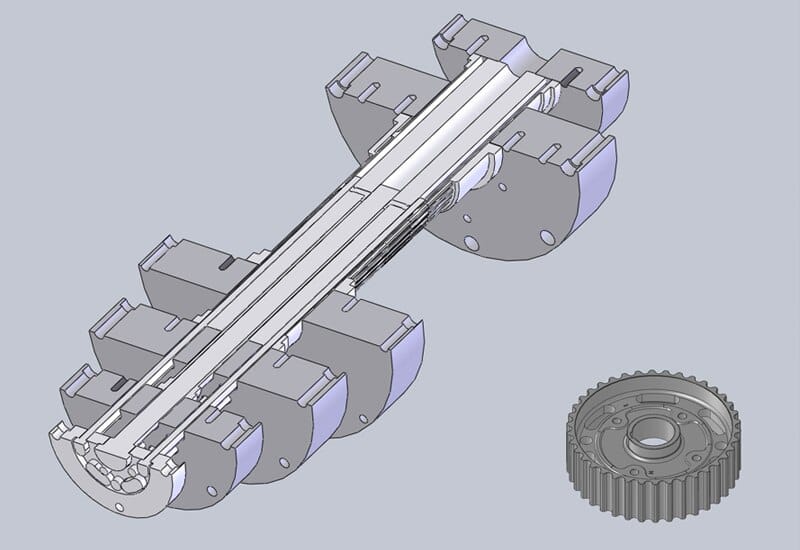

Sintered Gear Rotor for Oil Pump

Sintered oil pump gears have tight dimensional tolerances, parallelism and perpendicularity, and their mass production is cost-effective.

Sintered Oil Pump Rotor

Sintered oil pump rotor is produced by pressing and sintering metal powder; it is a green manufacturing process.

Powder Metal Oil Pump Rotor

Powder metal oil pump rotor uses metal powder as raw material, less material waste, and has tight torlerance.

Tractor Oil Pump Rotor

Tractor oil pump rotor manufactured by powder metallurgy allows the inner and outer rotors to be precisely connected.

What Is an Oil Pump Rotor?

An oil pump rotor is important rotating part of a trochoid or gerotor oil pump, widely used in automotive engines. It consists of an inner and outer rotor that form variable chambers to draw oil from the sump and send it under pressure to engine components, providing lubrication, cooling, and dependable operation.

Driven by the crankshaft through a transmission mechanism, the two parts rotate in sync, forming a series of enclosed chambers. On the intake side, as the chambers expand, a vacuum is created — drawing oil into the pump. As rotation continues, these chambers move to the outlet side, decrease in volume, and force the oil out under pressure.

Crucial to this process is the precision fit between the inner and outer rotor. To ensure consistent flow and reduce leakage, the radial clearance is kept tight — typically between 0.08 mm and 0.13 mm during assembly.

Oil Pump Rotor Manufacturing by Powder Metallurgy

Oil pump rotors made by powder metallurgy follow four steps: mixing, compaction, sintering, and secondary operations. First, iron-based powders such as FC-0208-60, FN-0208-30 or FL-4205-45 is mixed with binders including zinc stearate or lithium stearate to enhance flow and compaction. The powder blend is subsequently compacted in the die under 400–800 MPa to produce a green compact that determines the rotor shape and functional properties.

The compact is then sintered under a controlled atmosphere to about 1120◦C, (the residues from firing can be used as the controlled atmosphere) causing solid-state diffusion to bond particles together, and densify/strong and structurally stabilize. This intermediate stage converts the delicate green compact into a dense rotor that satisfies mechanical load needs.

After sintering, secondary operations like cnc machining and sizing are adopted to achieve the basic tolerance. The method developed allows having such key features as outer diameter, end faces, internal cycloidal profile, and involute spline with smooth rotation characteristic and high performance stability in a high-speed oil pumps.

Why Choose BLUE?

BLUE is your reliable choice for excellent oil pump rotors, offering tight tolerances, free mold design, fast delivery, and competitive pricing from China.

BLUE Quality Standards

BLUE assures your product quality with ISO 9001:2015 certified quality management system. We provide a one-year warranty on your oil pump rotors. Explore more about our high quality standard.

Standard Oil Pump Rotor Shop

BLUE provides sintered rotors for gasoline and diesel engines with quick delivery and no mold fees. Explore our online shop to find what exactly match yours.

Free Mold Design Support

With over 20 years of expertise in mold design, BLUE offers free, high-precision mold design services to meet your customized needs. Let our experience work for you!

BLUE High Quality Assurance

BLUE is ISO 9001: 2015 certified and applies the most stringent quality control measures throughout the manufacturing process of oil pump rotors.

We perform metallographic analysis of our products, dimensional and positional tolerance control, hardness, tensile and fatigue strength testing to ensure that our products meet higher quality standards.

In addition, we have perfect packaging capabilities to assurance that your oil pump rotors are delivered safely and intact, just like they were just produced.

These highest and strictest quality management measures ensure that each of your oil pump rotor has the precision, strength, and wear resistance to achieve the best engine performance.

Standard Oil Pump Rotors

BLUE has a wide range of oil pump rotor models, covering oil pumps for various motorcycles and cars.

We are committed to the standardization of powder metallurgy parts to improve production efficiency and eliminate mold costs.

Our oil pump rotors cover Toyota, Ford, Honda, BMW, Nissan, Volkswagen, Audi, Mazda, Suzuki, Kawasaki and other brands.

Free download of all our standard sintered oil pump rotors – just click the button below to signup!

Applications of Oil Pump Rotor

BLUE’s oil pump rotors have been applied in Weichai, Cummins, Honda, Toyota, and many other engines.

When these vehicles are driving at high speeds, the engines run violently and need lubricating oil protection. Therefore, the oil pump rotor is indispensable.

In addition, some mechanical equipment also needs lubricating oil to protect the engine. The oil pump rotor pumps out lubricating oil to ensure the smooth operation of the equipment.

Mechanical Properties of Oil Pump Rotors Materials

Here are some common mechanical properties of oil pump rotors materials. The inner rotor typically uses FN-0208-30, while the outer rotor uses FL-4205-45. Free to ask our team if you have any questions about materials.

| Model | Density | Tensile Strength | Hardness |

|---|---|---|---|

| FN-0208-30 | 6.70 g/cm3 | 310 Mpa | 63 HRB |

| FL-4205-45 | 7.10 g/cm3 | 460 Mpa | 70 HRB |

| FC-0208-50 | 6.70 g/cm3 | 410 Mpa | 73 HRB |

| FD-0205-50 | 6.95 g/cm3 | 540 Mpa | 76 HRB |

| FD-0208-55 | 6.90 g/cm3 | 540 Mpa | 83 HRB |

| FD-0405-60 | 7.05 g/cm3 | 710 Mpa | 85 HRB |

FAQ's

Here are some of the questions we get asked often. If yours isn’t answered, don’t hesitate to contact us, we’re happy to help!

The rotor oil pump has the following advantages:

- Small size

- Light weight

- Compact structure

- Low noise during operation

- High oil suction vacuum

- Large oil pump volume

- Good oil supply uniformity

The oil pump rotor is important for oil transfer within the oil pump.

To maintain its performance, follow these precautions:

Inspect for Damage and Wear:

Regularly check the oil pump rotor for any signs of damage or wear that could affect oil supply.

Clean the Surface:

Keep the rotor surface clean to prevent contaminants from interfering with oil pump operation.

Use High Quality Oil:

Regularly replace or top up with high-quality oil to ensure proper lubrication of the oil pump rotor.

The best industrial oil pump rotor depends on your applications. Gear rotors are widely used for fast and stable oil transfer in hydraulic and lubrication systems, while piston pumps perform better in high-pressure and high-precision applications. For handling corrosive or viscous fluids, tri-rotor pumps provide smooth flow and strong durability.

Powder metallurgy oil pump rotors stand out for their precision and consistency. Their sintered microstructure provides uniform density, excellent wear resistance, and tight dimensional control.

Oil pump rotor designs differ mainly in how they displace and pressurize oil.

Gerotor pumps use an inner and outer rotor with offset lobes, creating expanding and contracting chambers that move oil smoothly with high volumetric efficiency and low noise.

Gear pumps employ intermeshing external or internal gears to push oil between teeth, offering durability and simple construction but slightly more pulsation and leakage.

Vane pumps rely on sliding blades within an eccentric housing to deliver adjustable flow and precise pressure control, though they are less common in modern engines.

Roller gerotor pumps replace the outer rotor wall with rollers, reducing friction and bypass leakage, improving torque efficiency and wear resistance.