Manufacturers tend to use casting when considering cost performance and higher product strength. However, it also has disadvantages, such as material waste.

You may be familiar with powder metallurgy (PM), renowned for its ability to rapidly produce complex parts.

How to choose these two manufacturing processes?

If you look forward to comparing powder metallurgy vs. casting, you are at the right place.

Contents

Powder Metallurgy Vs. Casting Overview

Casting and powder metallurgy both use molds to shape raw materials into parts. Both can produce net shape or near-net shape parts.

What sets them apart greatly is that the casting process melts metal to form parts, while powder metallurgy forms parts below the melting point.

What is PM?

Definition of PM

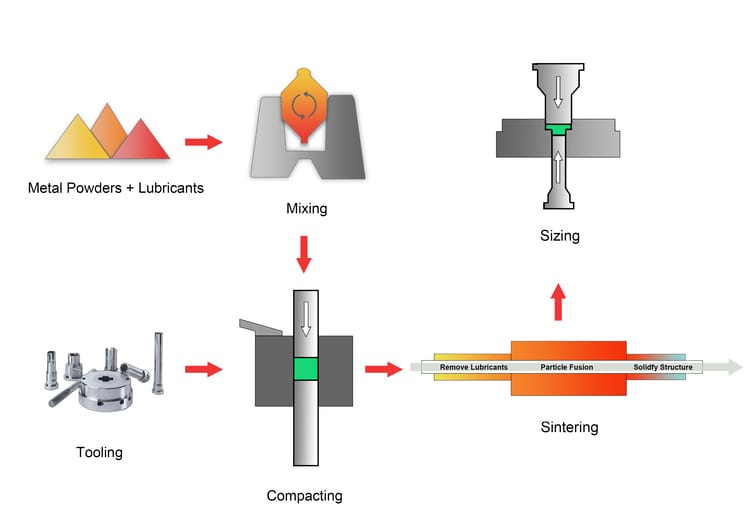

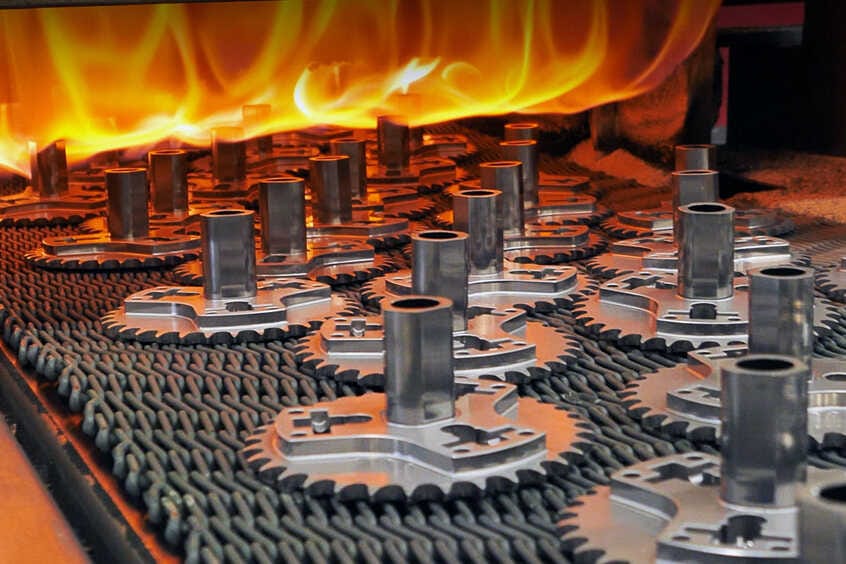

Powder metallurgy process creates metal components by heating compacted metal powders just below their melting point.

Types of Powder Metallurgy Process

Here are the common types of powder metallurgy process.

- Conventional Powder Metallurgy

- Metal Injection Molding (MIM)

- Hot Isostatic Pressing (HIP)

- Cold Isostatic Pressing (CIP)

- Spark Plasma Sintering (SPS)

- Powder Forging (PF)

- Additive Manufacturing (AM)

What is Casting?

Definition of Casting

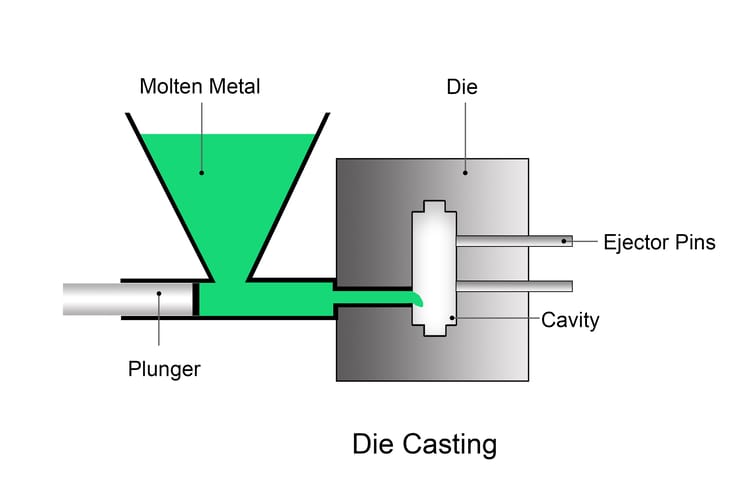

Casting process is to introduce molten metal into a mold to form the desired shape of the part. It is an ancient manufacturing process, with the earliest surviving castings dating back to 3200 BC.

Types of Casting

- Sand Casting

Sand casting uses sand molds to create parts. These molds are usually more cost-effective and sufficiently refractory.

- Die Casting

Die casting produces cast parts by forcing molten metal into a mold under high pressure. Die casting can produce components with a very good surface finish. Molds used for die casting are more expensive and have a longer service life.

- Investment Casting

Investment casting is a precision casting process that coats a wax pattern with ceramic to form the casting. Investment casting pieces have the following advantages:

- Perfect surface finish

- High dimensional accuracy

- Effective utilization of metal material

- Gravity Die Casting

Gravity casting uses gravity alone to pour molten metal into a mold. Gravity die casting has low production costs but a long production time.

- Continuous casting

Continuous casting produces continuous lengths of polygonal metal shapes. Compared with traditional casting, continuous casting can reduce both costs and energy consumption.

Advantages of Powder Metallurgy Vs. Casting

When comparing powder metallurgy to casting, we typically consider the following factors:

- Cost

- Raw Material

- Mechanical Properties

- Dimensional accuracy

- Environmental friendly

- Application

- Cost

Powder metallurgy equipment is usually more expensive, but the production efficiency is high. Sintered parts require less secondary operations, while cast pieces require more secondary processing. Besides, powder metallurgy mostly adopts fully automated processes, which greatly reduces labor costs.

- Higher Material Efficiency

Compared with cast iron, powder metal components are formed by pressing powder, with a high material utilization rate. Most castings require secondary processing to trim or machine away excess material.

- Precise Tolerances

Powder metallurgy components can achieve very high dimensional accuracy, especially after the sizing process. Generally, sintered parts can achieve an accuracy of about ± 0.04 mm. Casting, particularly sand casting, usually has lower dimensional accuracy compared to PM.

- Mechanical Properties

PM products often have a more uniform microstructure, leading to consistent mechanical properties.

Achieving optimal properties can be more difficult in casting process due to issues like segregation and porosity.

But cast pieces form a more compact structure during solidification, it typically exhibit higher tensile and yield strength.

- Surface Finish

PM parts typically have a finer surface finish with a Roughness Average (Ra) of 1.6 µm. This reduces the need for secondary operations.

- Wide Range of Raw Materials

Most Castings are made from nonferrous materials such as:

- Zinc

- Copper

- Aluminum

- Iron

- Magnesium

Because those metals have low melting points.

Powder Metallurgy has a wider range of material selection.

- Iron

- Copper

- Stainless steel

- Nickel

- Chromium

- Manganese

- Sulfur

- Phosphorus

- Silicon

- Production time

PM can be faster for producing components in high volumes due to its streamlined compaction and sintering process. The elimination of extensive machining and finishing steps also contributes to faster overall production times.

- Environmental Benefits

PM process often consumes less energy compared to melting metals. And less material waste leads to more environmentally friendly production.

Melting metal during casting consumes a lot of energy and produces waste gases. In addition, the castings are mostly cooled with water, which can become contaminated with oil, grease, and metal residues.

Applications of Powder Metallurgy and Casting

In our daily life, there are many casting products and powder metallurgy products.

For example, the sturdy frying pans we use to cook delicious meals are crafted through casting. Meanwhile, the smooth and reliable bearings in the fans that keep us cool during hot summer days are engineered using powder metallurgy.

More important powder metallurgy applications are as follows:

- Engine parts for cars, such as connecting rods, valve guides, and cam followers

- Soft magnetic components for motors, transformers and inductors

- Tools for cutting and machining

- Porous filters for gas and liquid filtration

Other significant uses of casting include:

- Engine blocks, cylinder heads, and transmission housings for automobiles

- Turbine housings, compressor housings, and landing gear for aircraft

- Heavy machinery parts: Large, strong parts such as pump housings, valve bodies, and gears.

- Molds and dies for various manufacturing processes

- Structural components and accessories used in the shipbuilding industry

Choose the Process that Suits Your Project

When you need to quickly mass produce complex small and medium-sized components, powder metallurgy is obviously better. For larger and stronger parts, casting may be more suitable.

Moreover, you also need to consider the material of the parts. For example, for metals with higher melting points, such as stainless steel, powder metallurgy is obviously more suitable.

In addition, you should consider the cost factor, including materials, equipment, production efficiency, etc.

FAQ

1. What is the Pour in the Casting Process?

In the casting process, “pour” refers to the act of transferring molten metal into a mold. Once the molten metal cools and solidifies, the Casting components are formed.

2. How Long Does Casting Process Take?

The casting process time can vary significantly based on such factors:

- The size and complexity of the part

- The specific casting method used

- The production volume.

Casting can take several weeks. For large and complex parts, it can take up to a month.