Custom Powder Metallurgy Part in China | BLUE

BLUE offers 500+ precision-engineered crankshaft sprockets without tooling fees. Designed for a perfect fit in timing systems, our crankshaft sprocket gears are compatible with a wide range of automobiles, including Toyota, Mazda, Honda, Land Rover, Chevrolet, Volkswagen, BMW, Audi, Peugeot, and more.

#1 Powder Metallurgy Company of Standard Parts

Free Download Powder Metallurgy Product List

Custom Powder Metallurgy Part in China

Why Choose BLUE?

As a leading powder metal parts manufacturer, BLUE provides top-quality powder metallurgy parts with advanced PM machines, strict quality control, and free mold design – guaranteeing excellence across our entire parts range.

BLUE Quality Standards

BLUE assures your product quality with ISO 9001:2015 certified quality management system. We provide a one-year warranty on your products.

Standard Parts Shop

With over 20 years of expertise in mold design, BLUE offers free, high-precision mold design services to meet your customized needs. Let our experience work for you!

OEM/ODM Services

Using advanced equipment, we provides free mold design based on your drawing and offers assistance with your customized product processing.

BLUE's Other Manufacturing Capabilities

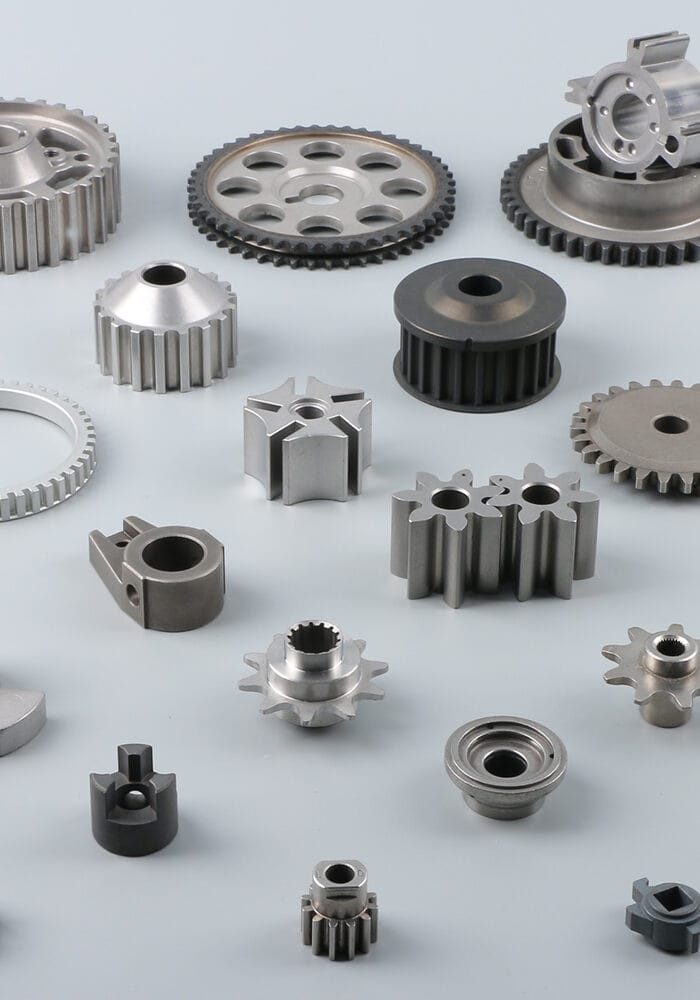

BLUE covers the full range of powder metallurgy processes, providing one-stop customization for powder metallurgy parts, MIM parts, sintered filters, and sintered ceramic components with strict quality control.

PM Parts

BLUE offers high-precision, strong powder metallurgy parts, customized to meet strict quality standards for various applications.

MIM Parts

BLUE's MIM parts feature flexible designs and top strength, produced with consistent quality for complex requirements.

Sintered Filters

BLUE's sintered filters are designed to resist corrosion, so it can perform reliably and durable even in harsh chemical environments.

Sintered Ceramics

BLUE's sintered ceramics offer excellent resistance to high temperatures and corrosion, along with good strength, hardness, and surface finish.

Wide Selection of Sintered Standard Parts

BLUE offer a wide range of powder metallurgy standard parts, such as: oil pump rotor & gear, water pump pulley & flange, sintered filter element, oil impregnated bushing, etc. we also provide customized parts, contact our team to tell us your needs.

Powder Metallurgy Materials

At BLUE, we have technical expertise and strict quality control to ensure high-quality powder metallurgy molds.

We use advanced software and manufacturing techniques and conduct rigorous inspections and testing to meet our customers’ expectations of a variety of powder metallurgy parts.

All your design 3D models and drawings will be kept strictly confidential and will not be shared with any third party or used for publicity.

Powder Metallurgy Tolerances

BLUE is committed to using the highest-quality raw materials for our powder metallurgy toolings from ASSAB in Sweden, a world-renowned material supplier.

We believe that using top-quality materials is critical to achieving the best possible results, which is why we trust them to deliver the consistent quality that we demand.

In addition, they are also takes full responsibility for the heat treatment process, by carefully controlling the heat treatment process, we can maximize the performance and lifespan of each mold, and ensure that our customers receive powder metal toolings of the highest quality.

Powder Metallurgy Standards

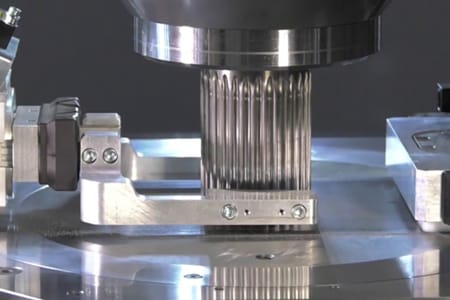

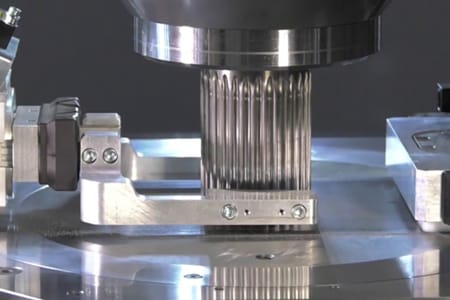

We believe that precision is crucial to producing high-quality powder metallurgy tooling, which is why we choose WEDM from Agie GF in Switzerland.

Agie GF is a world leader in the field of electrical discharge machining (EDM/WEDM), and their equipment is renowned for its precision, reliability and trustworthy.

With the state-of-the-art equipment, we are able to achieve world-class precision in every set of sintering molds that we produce, delivering exceptional quality and value to our customers.

Secondary Processing of Powder Metallurgy

BLUE is dedicated to providing our customers with the highest level of quality, and we believe that the best way to achieve this is by completing every process in our own factory.

By handling all the manufacturing process, from design and engineering to production and finishing, we are able to maintain tight control over every step and ensure the highest standards of quality, cost-effectiveness, and timely delivery.

We can offer greater flexibility, efficiency, and quality control, your trusted supplier of powder metallurgy toolings in China.

Powder Metallurgy Process

Powder Production

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur

Mixing

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Compacting

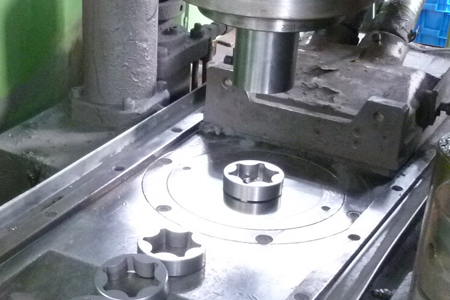

Conpacting is a process that presses metal powder into mold cavity through powder compaction machine to get a green compact part.

Conpacting is a process that presses metal powder into mold cavity through powder compaction machine to get a green compact part.

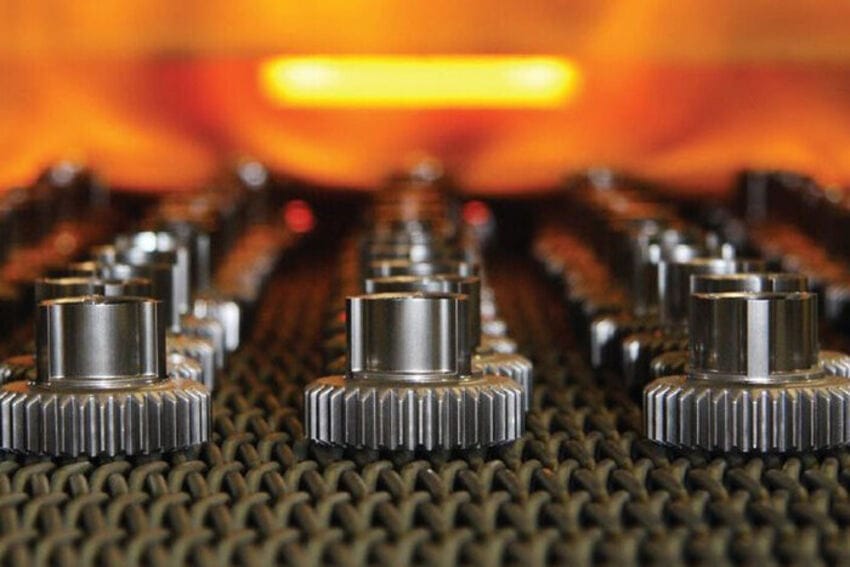

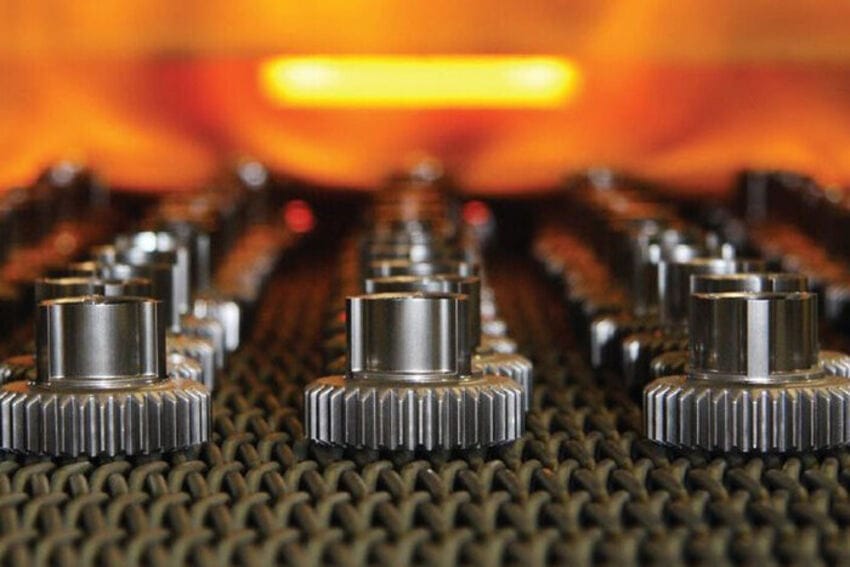

Sinteirng

Sintering heats the green compact to a temperature below its melting point in a controlled atmosphere to obtain the desired mechanical properties.

Sintering heats the green compact to a temperature below its melting point in a controlled atmosphere to obtain the desired mechanical properties.

BLUE Powder Metallurgy Processes

Powder metallurgy is a precision manufacturing process with a continuing and stable accuracy of up to 0.01mm, which requires strict control at each stage to ensure the quality of the final part. Any deviation or error during the process may result in the rejection of the entire batch.

Designing

Mold design is a critical process that must consider the desired part geometry, material properties, production volume, and cost-effectiveness.

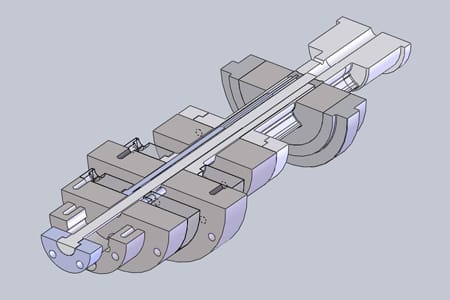

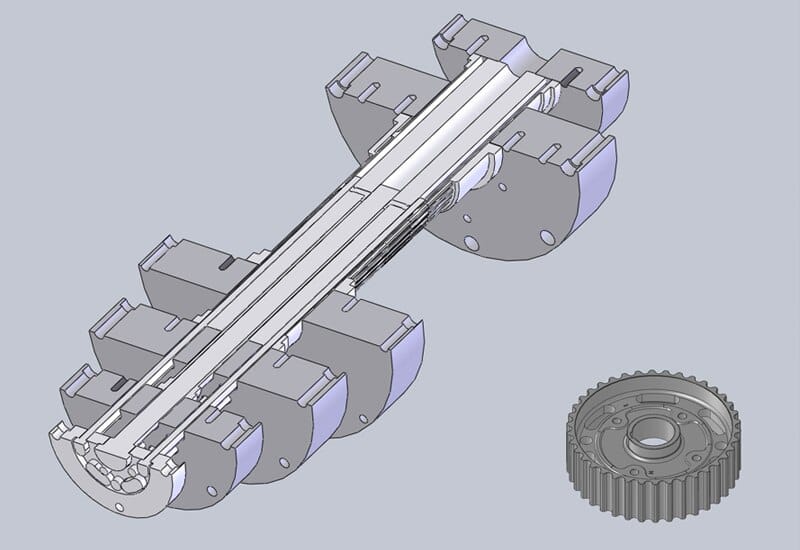

Tooling

Powder metallurgy tooling includes upper and lower punches, die, and core rod. The mold needs to have excellent strength, hardness and wear resistance.

Mixing

Mixing is the process of blending metal powder with binders to improve its uniformity and fluidity, promoting better material consistency.

Compacting

Conpacting is a process that presses metal powder into mold cavity through powder compaction machine to get a green compact part.

Sintering

Sintering heats the green compact to a temperature below its melting point in a controlled atmosphere to obtain the desired mechanical properties.

Sizing

Sizing corrects dimensional deviations after sintering and enhances product accuracy. It requires an additional, simpler set of molds compared to the forming mold.

Tumbling

Tumbling removes burrs and flash from a part's surface by vibrating it with abrasive media, such as stone or ceramic, resulting in a smoother finish.

Machining

Machining can achieve complex shapes that cannot be pressed by powder metallurgy, such as transverse holes and screw threads.

Blackening

Blackening process, or steam treatment, forms an oxide layer to prevent rust and increase hardness, offering a cost-effective solution.

Hardening

Hardening enhances the material's strength and hardness through carburizing or nitriding, resulting in improved wear resistance and fatigue life.

Inspecting

The inspecting process is always a critical step that ensures quality and performance through BLUE inspection standards before shipping.

Packaging

BLUE's packaging process uses anti-rust paper, vacuum, blister and other methods to ensure that the product is intact during transportation.

Equipment for Customizing Powder Metallurgy Parts

BLUE has a complete range of advanced powder metallurgy production equipment, including 25T to 1000T compaction press, conveyor belt sintering furnace, vacuum sintering furnace, sizing press, CNC machining equipment, Machine Center, hardening furnace, etc.

Custom Powder Metallurgy Parts Capabilities

The following are BLUE’s custom powder metallurgy parts capabilities, including part size, weight, wall thickness, surface roughness, etc.

| Attribute | Value |

|---|---|

| Size | Diameter 5 to 250 mm |

| Length | 5 to 200 mm. |

| Wall thickness | Minimum wall thickness is 1.5mm |

| Surface finish | Ra 0.8μm to Ra 1.6μm |

| Weight | 3 to 2000 grams |

| Tolerance | ±0.01 mm |

| Sintered Hardness | 50-70 HRB |

| Hardened Hardness | 30 HRC min |

| Material | All materials comply with MPIF 35 or DIN 30910 or JIN Z 2550 standards |

Custom Powder Metallurgy Parts Capabilities

The following are BLUE’s custom powder metallurgy parts capabilities, including part size, weight, wall thickness, surface roughness, etc.

| Attribute | Minimum | Typical | Maximum |

|---|---|---|---|

| Component Mass (g) | 0.030 | 10-15 | 300 |

| Dimension (mm) | 2.0 (0.08 in) | 25 (1 in) | 150 (6 in) |

| Wall Thickness (mm) | 0.025 (0.001 in)* | 5 (0.2 in) | 15 (0.6 in) |

| Tolerance (%) | 0.2% | 0.5% | 1% |

| Density | 93% | 98% | 100% |

| Production Quantity | 1000 | 100,000 | 100,000,000 |

| *Features this small could have distortion | |||

More about BLUE's Powder Metallurgy Products

BLUE pays great attention to production details, mature manufacturing processes, advanced equipment and strict quality control inspection to ensure their products are precise, accurate and of the highest quality.

A Wide Range of Standard Sintered Parts

BLUE provides a full range of standard sintered metal parts, along with free mold design services and complimentary samples to suit your needs.

Oil Pump Rotor

Oil pump rotor is composed of an inner and outer rotor and is responsible for distributing lubricating oil throughout the engine.

Oil Pump Gear

An oil pump gear is a core component in oil pump that pressurize and circulate oil throughout an engine's lubrication system.

Oil Impregnated Bushing

Oil-impregnated bushings are self-lubricating bearings made via powder metallurgy that release oil during operation to reduce friction.

Water Pump Flange

Water pump flange is a connecting element on a water pump that allows for secure attachment to pipes or other components.

Timing Pulley

A timing pulley is a toothed wheel that meshes with a timing belt to synchronize the movement of engine or mechanical components.

Water Pump Pulley

Water pump pulley works with the belt to circulate coolant throughout the engine to maintain optimum operating temperature.

ABS Ring

ABS ring is a toothed ring on the wheel hub or axle that works with ABS sensor to detect wheel speed for anti-lock braking system.

Sintered Filter

Sintered filters are porous components formed by pressing or vibrating powder particles, followed by the sintering process.

Sintered Muffler

Sintered silencer is a cost-effective solution to aerodynamic noise and can also filter impurities in the gas.

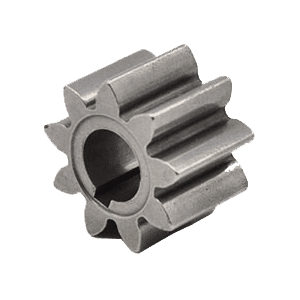

Powder Metal Gear

Powder metal gears are made from metal powders that are compacted and sintered to form solid parts with tight tolerance.

Synchronizer Ring

Synchronizer ring is a part in manual transmission that helps match gear speeds for smooth shifting.

Valve Guides

Valve guides are cylindrical bushings in engine that provide a stable path for the valves and maintain their alignment during operation.

Application of Customized Powder Metallurgy Parts

BLUE’s expertise in designing and manufacturing a wide variety of powder metallurgy molds enables our customers to produce high-quality and precision powder metal parts with complex shapes and features.

Powder Metallurgy in Automotive Applications

With the advancement of technology, powder metallurgy in automotive applications is becoming more widespread. Do you know how many powder metal parts are in an

Powder Metallurgy Applications in Power Tools

Power tools make everyday work tasks a lot easier. Today, power tools are moving towards being compact, lightweight, and safe. This naturally goes hand in

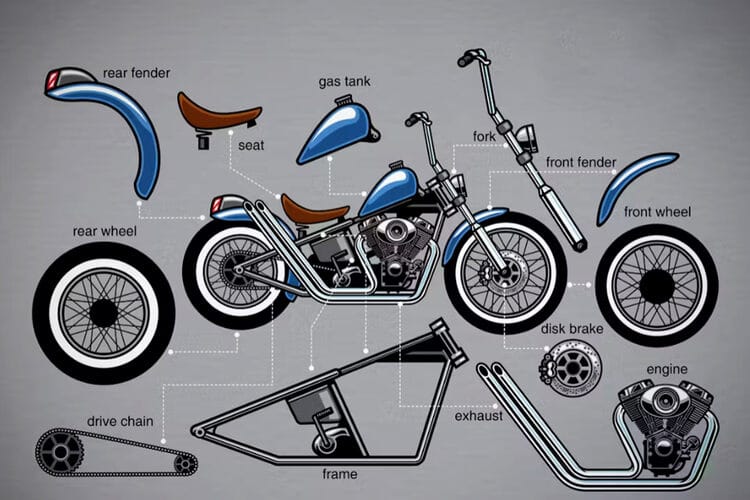

Powder Metallurgy Applications in Motorcycles

Motorcycling is closer to nature and easier to maneuver than driving. Many young people like this cool and exciting mode of transportation. Motorcycles are also

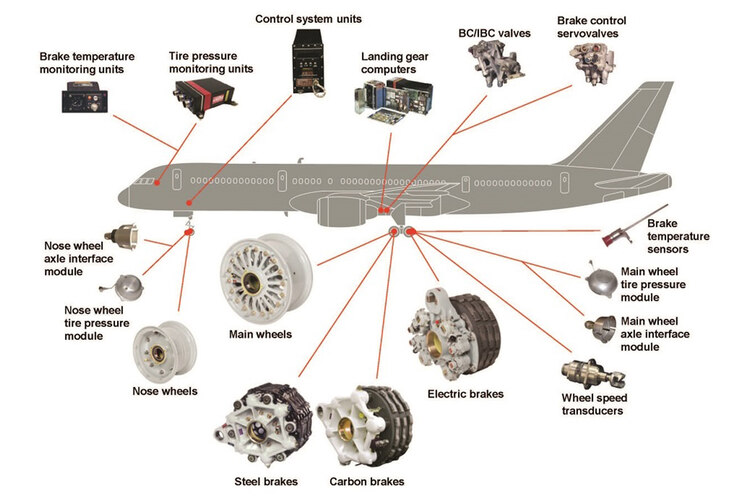

Powder Metallurgy Applications in Aerospace

You may have heard that powder metallurgy (PM) is widely applied in the mechanical industry. But do you know about powder metallurgy applications in aerospace?

Metal Injection Molding (MIM) Medical Applications

As the population ages, the health of the elderly deserves more attention. This is inseparable from advanced medical technology and equipment. It goes without saying

How to Custom a Powder Metallurgy Part in BLUE?

BLUE employs advanced technology and skilled personnel to manufacture and inspect high-quality powder metallurgy molds and other accessories.

- 3 Days | Mold Design

BLUE is committed to completing the mold design within 3 days, providing more efficient and high-quality services.

- 7 Days | Production

we are dedicated to completing all machining processes within 7-15 working days, ensuring the fastest use by customers.

- 1 Day | Inspection

BLUE prioritizes quality testing and dedicate 1 day to ensuring that every mold meets our rigorous standards.

- 5 Days | Shipment

BLUE securely packages and ships all sintered metal toolings by air couriers, arriving within 5 days on average.

Frequently Asked Questions

Below are answers to some common questions about powder metallurgy, However, if you still have any other questions, please feel free to contact us.

Powder Metallurgy VS. Stamping

Powder metallurgy uses metal powder as the raw material, while stamping uses flat metal sheets.

Powder metallurgy is suitable for high-volume manufacturing of complex-shaped parts, whereas stamping is faster for producing simple shapes in large quantities.

Powder Metallurgy VS. Machining

Powder metallurgy produces components through die compaction and sintering, while machining removes material from a solid block to achieve the desired shape.

Powder metallurgy is ideal for large quantities and complex, intricate features, whereas machining is better suited for precise dimensions and smaller batches.

What is Compaction in Powder Metallurgy?

In powder metallurgy, “compaction” is the process of applying high pressure to metal powder within a die to shape it into the desired form.

The pressed metal powder, known as “green compact”, is typically pressed by mechanical or hydraulic presses…

What is Blending in Powder Metallurgy?

Blending is the process of mixing different metal powders with binders and lubricants to enhance powder fluidity, improve compressibility, and reduce demolding force.

Some common lubricants include Acrawax, zinc stearate, and lithium stearate…

What is Sizing in Powder Metallurgy?

Sizing in powder metallurgy is a secondary operation performed on sintered components to achieve tighter tolerances.

After sintering, powder metal parts may undergo slight dimensional changes due to shrinkage or distortion.

Sizing corrects these deviations by re-press the sintered part into the die.

What are Secondary Operations in Powder Metallurgy?

Sintered parts gain additional features or improved mechanical properties and surface finish through secondary operations. Common secondary operations include:

What is Sintering Process in Powder Metallurgy?

Powder metallurgy sintering is a manufacturing process in which green compacts are heated to a temperature below their melting point in a controlled atmosphere.

The heat causes the metal particles to bond, reducing porosity and increasing density.

This fusion imparts structural integrity and enhances the material’s mechanical properties, resulting in a strong and durable final product…

Powder Metallurgy VS. Casting

Both casting and powder metallurgy are near-net-shape processes that use molds to shape raw materials into components.

Casting melts the metal to create the part, while powder metallurgy shapes the part at temperatures below the metal’s melting point.

Powder Metal Parts VS. Forged Parts

Powder metallurgy forms components through die compaction and sintering at temperatures below the metal’s melting point, while forging deforms heated or cold metal under high pressure to achieve the desired profiles.

PM is better suited for producing complex-shaped parts with controlled porosity, while forging is ideal for simple shapes requiring high strength and durability.

What is Metal Injection Molding Process?

Metal Injection Molding (MIM) is a manufacturing process that combines the plastic injection molding with the precision of conventional powder metallurgy.

Fine metal powder and binders are mixed to create feedstock. The feedstock is then molded by an injection molding machine, followed by debinding and sintering to produce the final product.

What is a Sintered Filter?

Sintered filters are manufactured by pressing metal powder into a mold and sintering it at high temperatures below the metal’s melting point.

Sintering process creates a solid, porous structure with fine interconnected pores that effectively capture contaminants while allowing liquids or gases to pass through.

What are the Advantages and Disadvantages of Powder Metallurgy?

Powder metallurgy is recognized as a green manufacturing process with numerous advantages.

It offers cost-effective mass production, high material utilization, consistent batch-to-batch quality, minimal secondary processing, and low energy consumption.

Sintered Metal Product Manufacturer

Sintered metal product are manufactured through powder metallurgy process where metal powder particles are pressed into a desired shape and then sintered below their melting point…

What is Powder Metallurgy Process?

Powder metallurgy process is a metal-forming method that presses metal powders and sinters green compacts below their melting points to create the final component.

It is a near-net-shape process, allowing the production of complex geometries and intricate features…

Powder Metallurgy Materials

The following are powder metallurgy materials classified according to the MPIF, with ferrous powder metallurgy materials being the most commonly used.

Unalloyed PM iron and carbon steels (F-0000, F-0005, F-0008) are produced from essentially pure iron powder with controlled carbon additions via graphite, pressed and sintered to the required density. The standard material designations are:

F-0000:

F-0005:

F-0008:

Iron-copper and copper-steel powder metallurgy materials are made by blending elemental iron powder with copper powder, with or without graphite.

Copper increases strength, hardness, and wear resistance, while graphite provides carbon for additional strengthening during sintering. These alloys are widely used in medium-strength structural parts, and can be heat treated for higher wear resistance or oil-impregnated for self-lubricating applications.

The commonly used material designations include:

FC-0200

FC-0205

FC-0208

FC-0505

FC-0508

Iron-nickel powder metallurgy steels are produced by mixing elemental iron powder with 1–4% nickel powder and, when needed, graphite for carbon.

Nickel additions create nickel-rich phases that improve toughness, tensile strength, and hardenability, making these materials suitable for heat-treatable structural parts requiring strength, wear resistance, and good impact properties. Common material designations include:

FN-0200

FN-0205

FN-0208

FN-0405

FN-0408

Prealloyed low-alloy steel powders in powder metallurgy are made with nickel, molybdenum, manganese, and chromium as key alloying elements, with graphite added to achieve the desired carbon content.

These materials are favored for medium- to high-density applications where heat-treated parts must deliver high strength and wear resistance, offering greater hardenability than copper- or nickel-steel blends.

Common material designations include:

FL-0405

FL-4205

FL-4400

FL-4405

FL-4805

Hybrid low-alloy steels are made by combining prealloyed low-alloy steel powders (with nickel, molybdenum, and manganese) and additional elemental metals, plus graphite for carbon control. They are chosen for applications needing heat-treatable, high-strength, and wear-resistant parts. Commonly used material designations include:

FLN2C-4005

FLN4C-4005

FLN-4205

Sinter-hardened steel is produced from low-alloy steel powders containing nickel, molybdenum, chromium, manganese, and sometimes copper. It is engineered to achieve high hardness and strength directly during the cooling phase after sintering, with a primarily martensitic microstructure often containing fine pearlite, bainite, and retained austenite for improved wear resistance. Common material designations include:

FLN2-4408

FLN4-4408

FLNC-4408

FLC-4608

FLC2-4808

Diffusion-alloyed steel is made from steel powders in which nickel, copper, and molybdenum are partially bonded to the particle surfaces, with graphite added to achieve the desired carbon content. It offers medium to high strength, can be heat treated for improved wear resistance, and typically shows a mix of bainite and martensite in its microstructure.

Common material designations include:

FD-0200

FD-0205

FD-0208

FD-0400

FD-0405

Copper-infiltrated steel is made by compacting iron-based powders, then filling interconnected pores with molten copper during sintering. This process boosts strength, hardness, impact resistance, and pressure tightness, while improving machinability and enabling surface treatments like carburizing or induction hardening.

Common material designations include:

FX-1000

FX-1005

FX-1008

FX-2000

FX-2005

Prealloyed austenitic stainless steel powders are used in PM to produce dense, homogeneous parts with good corrosion resistance and mechanical strength. Common grades like SS-303, SS-304, and SS-316 differ in machinability, corrosion resistance, and general-purpose suitability, with all being non-magnetic.

Common material designations include:

SS-303N1, N2

SS-303L

SS-304N1, N2

SS-304H, L

Ferritic and martensitic stainless steels are produced from prealloyed powders, sometimes with added graphite to control carbon content.

They are mainly used when magnetic properties or heat-treat response are required, offering lower corrosion resistance than austenitic grades but good strength, hardness, and wear resistance in specific alloys.

Common material designations include:

SS-409L

SS-410L

SS-430l

PM copper, brass, bronze, and nickel-silver for structural applications (excluding oil-impregnated bearings) are made from prealloyed powders, except for pure copper and bronze, which are usually produced from admixed elemental copper and tin powders.

Pure copper offers excellent thermal and electrical conductivity, while brass, bronze, and nickel-silver provide varying levels of strength, corrosion resistance, machinability, and attractive finishes for structural parts and hardware.

Common material designations include:

C-0000

CZ-1000

CZP-1002

Soft-magnetic PM alloys are made from iron-based powders, either unalloyed or combined with ferroalloys containing phosphorus or silicon, and in some cases prealloyed for iron-nickel systems.

They are designed to deliver high magnetic induction, low coercive field strength, and high permeability, making them suitable for DC magnetic field applications and certain structural uses requiring good ductility and impact resistance.

Common material designations include:

FF-0000

FY-4500

FN-5000

FAQ's

Here are some of the questions we get asked often. If yours isn’t answered, don’t hesitate to contact us, we’re happy to help!

Powder metallurgy has a wide range of material options, including:

- Ferrous materials

- Bronze

- Brass

- Aluminum alloys

- Stainless steels

- Titanium alloys

- Nickel-based super alloys

You can choose mixed powders and pre-alloyed powders to make powder metal parts.

Compacted metal powders only have a strength similar to chalk, making them prone to breaking and unable to meet usage requirements. Sintering is heating the green compact below the metal’s melting point, enhancing its strength, hardness, and other mechanical properties.

Powder metallurgy products contain internal pores, so they cannot achieve complete density like casting and forging. For example, iron-based powder metallurgy parts can reach 7.2 g/cm³ with one-time compacting and sintering. Using secondary compacting and secondary sintering or a copper infiltration process can achieve densities of 7.2 to 7.6 g/cm³. Powder forging can produce sintered metal parts exceeding 7.6 g/cm³, but the cost is greatly increased.

Why Choose Us for Powder Metal Manufacturing?

Our team of engineers, with 20 years of combined manufacturing and design experience, is ready to tackle your most challenging problems.

ISO 9001 Certified

BLUE is not only an ISO 9001:2015 certified supplier but also follows its own strict quality control system so every part you receive meets the highest standards.

Standard Part Shop

BLUE is committed to developing a library of standard powder metal parts. These standard parts require no tooling fees, thus reducing your production costs.

Mold Design Support

With over 20 years of manufacturing and design expertise, BLUE offers free, high-precision mold design services to meet your customized needs.

Production Capability

We have the ability to manufacture sintered metal parts ranging from 5 to 250mm in diameter and weighing 3 to 2000g, including: structural parts, sintered Bushings.

Find your Powder Metallurgy Standard Parts

What Is a Water Pump Flange ?

A water pump flange is a connecting element that secures the pump to the engine block or piping system, creating a stable and leak-free path for coolant or water circulation. What distinguishes it is the flat, bolted surface through which the pump’s inlet and outlet are joined to pipes or housings.

In automotive and industrial applications, manufacturers often choose sintered metals, since they allow cost-effective mass production while holding tight tolerances. When the flange is installed, gaskets or O-rings are typically added, so that the joint remains sealed under pressure and long service.

Production of Water Pump Flange by Powder Metallurgy Process

The following is a typical powder metallurgy route for manufacturing water pump flanges, consisting of mixing, pressing, sintering, and secondary operations.

Mixing

First, mixed the metal powder with a binder such as zinc stearate or lithium stearate. These binders aid powder flow, improve compressibility, and reduce the force required to release the pressed part from the mold.

Common water pump flange materials include FC-0205, FC-0208, and FN-0205.

Compacting

Mixed metal powder is compacted in a precision PM mold under high pressure (400–800 MPa) to form the green compact of the water pump flange.

This process establishes the flange’s basic geometry, including its profiles and dimensions. Although bulk density increases during compaction, the green compact still has low strength.

Sinteirng

Then, the green compact undergoes sintering process in a controlled atmosphere at a temperature lower than the metal’s melting point.

For ferrous materials, this is typically around 1120 °C. In this stage, solid-state diffusion bonds the particles, leading to higher density, improved strength, and enhanced structural integrity of the part.

Secondary Operations

Sintered water pump flanges may require secondary operations to obtain higher precision, surface roughness, or other features. For example, sizing can improve the dimensional accuracy of water pump flanges, and machining can improve surface finish.

Common surface treatments include steam treatment, Dacromet, electroplating, etc.